Degradation treatment method for eichhornia crassipes

A processing method and technology for water hyacinth, applied in the field of degradation treatment of water hyacinth, can solve the problems of water hyacinth lignin destruction, environmental pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

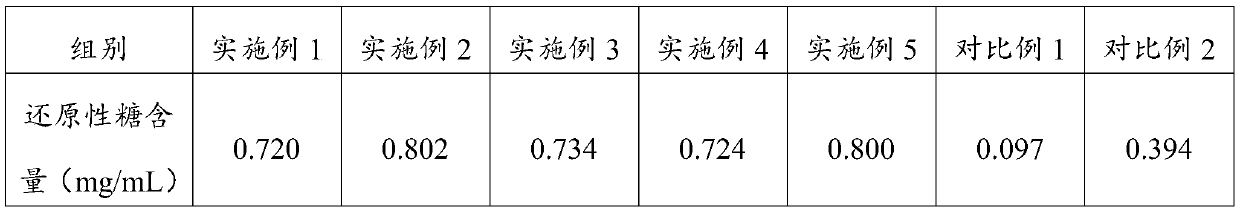

Examples

Embodiment 1

[0018] Preparation of oxidized electrolyzed water, the specific process is: use an electrolytic cell with a cathode chamber, a middle chamber and an anode chamber, the middle chamber is arranged between the cathode chamber and the anode chamber, the cathode chamber and the middle chamber Separated by an anion exchange membrane, the anode chamber is separated from the middle chamber by a cation exchange membrane, the cathode in the electrolytic cell is a pure titanium plate, and the anode in the electrolytic cell is a platinum electrode; and the negative electrode The volume ratio of chamber, middle chamber and anode chamber is 5:1:5.

[0019] Pipette the sodium chloride electrolyte solution with a mass fraction of 0.5% and pour it into the electrolytic cell, and the cathode chamber, the middle chamber and the anode chamber in the electrolytic cell need to be filled with sodium chloride electrolyte solution, and the electrolytic coefficient is set: power supply The voltage is 3...

Embodiment 2

[0023] Preparation of oxidized electrolyzed water, the specific process is: use an electrolytic cell with a cathode chamber, a middle chamber and an anode chamber, the middle chamber is arranged between the cathode chamber and the anode chamber, the cathode chamber and the middle chamber Separated by an anion exchange membrane, the anode chamber is separated from the middle chamber by a cation exchange membrane, the cathode in the electrolytic cell is a pure titanium plate, and the anode in the electrolytic cell is a platinum electrode; and the negative electrode The volume ratio of chamber, middle chamber and anode chamber is 5:1:5.

[0024] Pipette the sodium chloride electrolyte solution with a mass fraction of 0.5% and pour it into the electrolytic cell, and the cathode chamber, the middle chamber and the anode chamber in the electrolytic cell need to be filled with sodium chloride electrolyte solution, and the electrolytic coefficient is set: power supply The voltage is 3...

Embodiment 3

[0028] Preparation of oxidized electrolyzed water, the specific process is: use an electrolytic cell with a cathode chamber, a middle chamber and an anode chamber, the middle chamber is arranged between the cathode chamber and the anode chamber, the cathode chamber and the middle chamber Separated by an anion exchange membrane, the anode chamber is separated from the middle chamber by a cation exchange membrane, the cathode in the electrolytic cell is a pure titanium plate, and the anode in the electrolytic cell is a platinum electrode; and the negative electrode The volume ratio of chamber, middle chamber and anode chamber is 5:1:5.

[0029] Pipette the sodium chloride electrolyte solution with a mass fraction of 0.5% and pour it into the electrolytic cell, and the cathode chamber, the middle chamber and the anode chamber in the electrolytic cell need to be filled with sodium chloride electrolyte solution, and the electrolytic coefficient is set: power supply The voltage is 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com