Integrated printing and dyeing waste water treatment process

A technology for treating process and printing and dyeing wastewater, applied in the field of comprehensive printing and dyeing wastewater treatment process, can solve the problems of easy impact of biochemical treatment, reduced treatment efficiency, increased treatment cost, etc. Impact, effect of simplified distribution design

Inactive Publication Date: 2010-08-11

SHAOXING WATER TREATMENT DEV

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

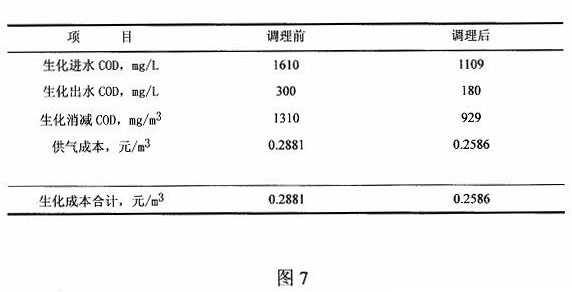

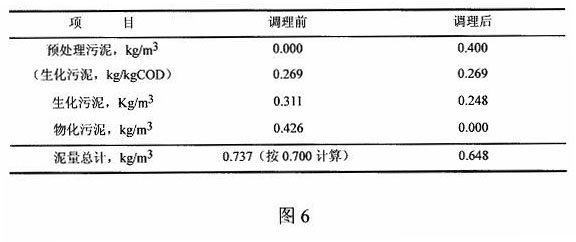

This combined biochemical treatment and physicochemical treatment wastewater treatment process can basically meet the standard of water quality COD and chroma after treatment, but the treatment process is more complicated, the treatment efficiency is reduced, and it is difficult to meet the needs of the design capacity, and because the biochemical treatment before The sewage water quality is not regulated, which makes the biochemical treatment susceptible to impact. In the process of biochemical treatment and physicochemical treatment, the consumption of chemicals and electric energy is high, which increases the unit treatment cost. Therefore, how to increase the efficiency of the existing sewage treatment process, Consumption reduction is a common problem faced by sewage treatment at present

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

This invention relates to a comprehensive process for treating dye waste-water comprising: pretreatment, biochemical treatment and wastesludge treatment. In the pretreatment, high efficiency water quality modulation agent is used for the reactions of: complexation with the organic substances, hydration, hydrolyzation and neutralization to reduce the content of soluble substances being of difficult to be degradation lowering alkalinity, reducing heavy metal ions. After that it is subjected to anaerobic treatment, where the devulcanization makes the decolourization of the dye and reducing COD content, the ion of Fe2+ reacts with S2-(the devulcanization product) to produce non-soluble sulfides. The residual of modulation agent in coordination with aerobic microganism proceed further biological reaction to increase the biochemical treatment effect. The effluent after thus treatment can be direct drained, meeting the national standards.

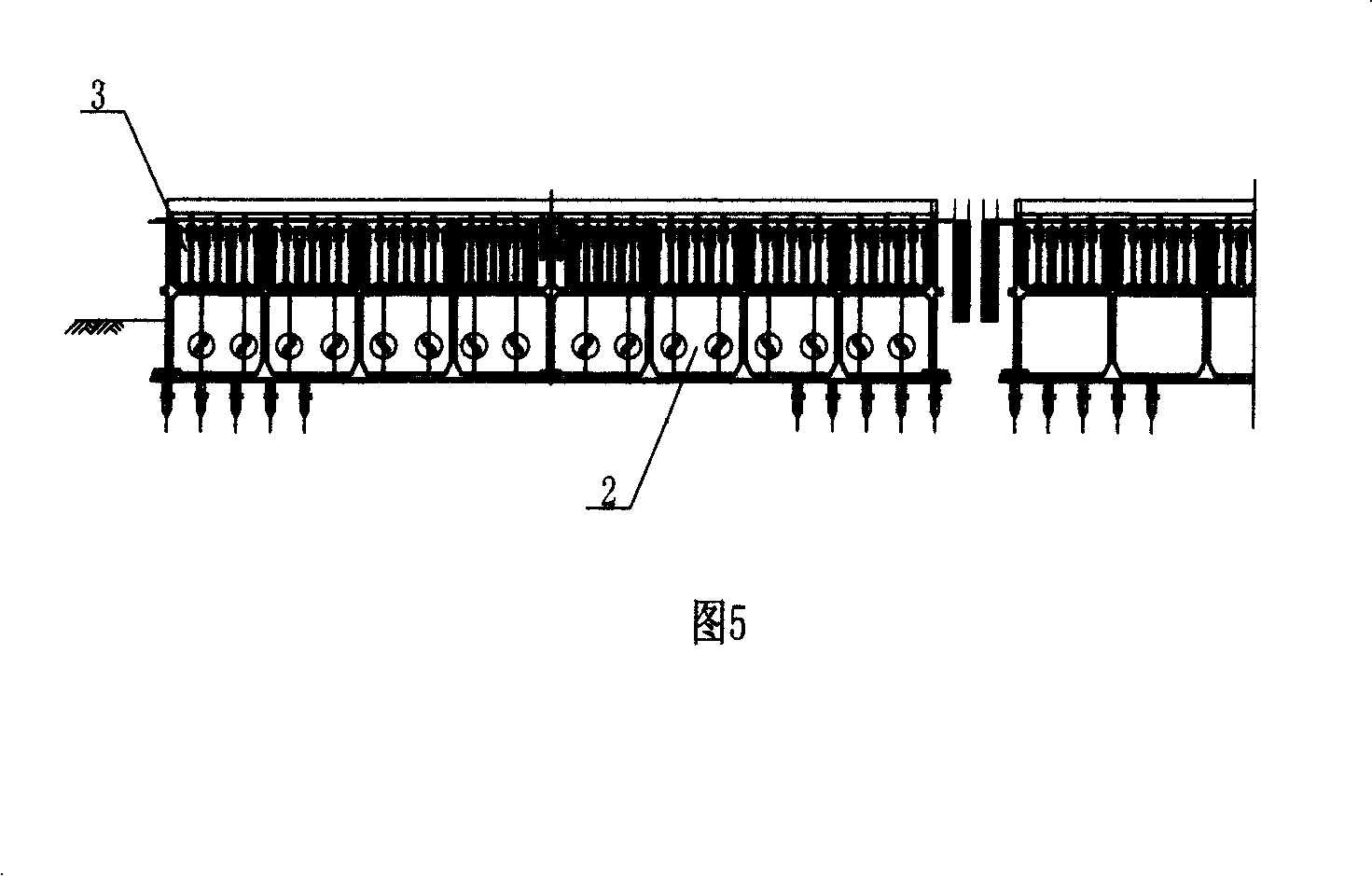

Description

technical field The invention relates to a treatment process of printing and dyeing wastewater, in particular to a comprehensive printing and dyeing wastewater treatment process integrating water quality conditioning, acidification hydrolysis, and intelligent oxygen supply and aeration. technical background With the development of urbanization and industrialization, the problem of water pollution has become increasingly prominent. Among them, printing and dyeing wastewater is one of the main industrial wastewater in my country. It has the characteristics of large water volume, high chroma, and complex composition, causing serious pollution to the environment. At present, the treatment methods of printing and dyeing wastewater mainly include chemical coagulation, biochemical treatment and physical treatment. The chemical coagulation method uses coagulants mainly composed of magnesium salts and iron salts. Cause secondary pollution; biochemical treatment is currently the main ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F9/14C02F3/28C02F11/12C02F1/66

Inventor 王欣张志峰蔡芝斌蔡建峰虞伟权沈荣根

Owner SHAOXING WATER TREATMENT DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com