Controllable shunt double-tungsten electrode coupling electric arc welding gun device based on center filler wire and welding method thereof

A technology of arc welding and tungsten electrode, applied in the field of welding equipment, can solve the problems of workpiece welding deformation, increase of welding heat input, expansion of heat-affected zone, etc., and achieve the effect of improving weld shape, strengthening accessibility and high melting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in more detail below in conjunction with accompanying drawing example:

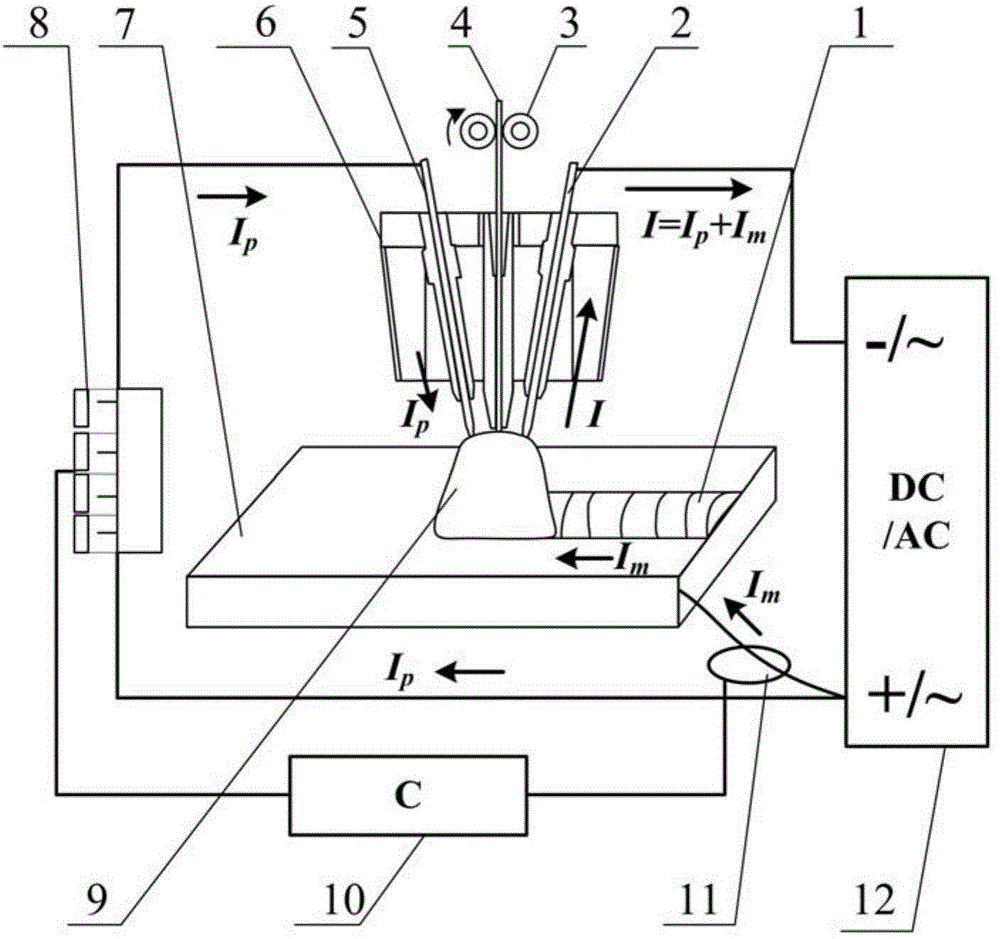

[0028] figure 1 It is the principle diagram of double tungsten coupled arc welding with center-filling controllable shunt, which mainly consists of wire feed wheel 3 , center-filling controllable shunt double tungsten-electrode arc welding torch 6 , IGBT current control module 8 , control system 10 , current sensor 11 and Welding power supply 12 and other components. During the welding process, the current sensor 11 is used to monitor the welding current flowing through the base metal, and the control system 10 and the IGBT current control module 8 are used to change the ratio of the main and bypass currents to achieve precise heating of the base metal and welding wire.

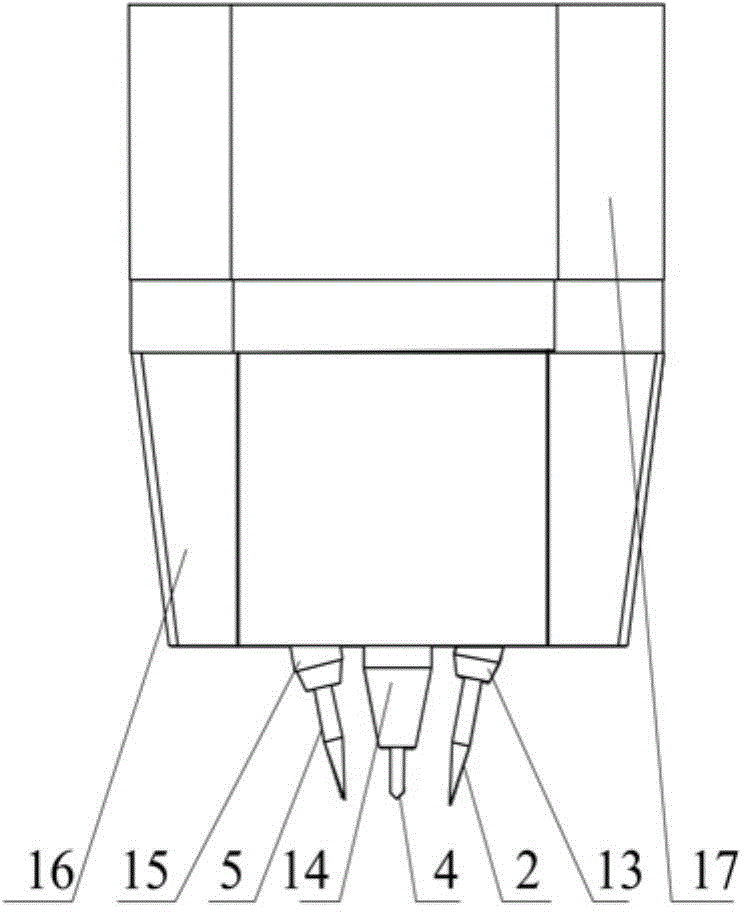

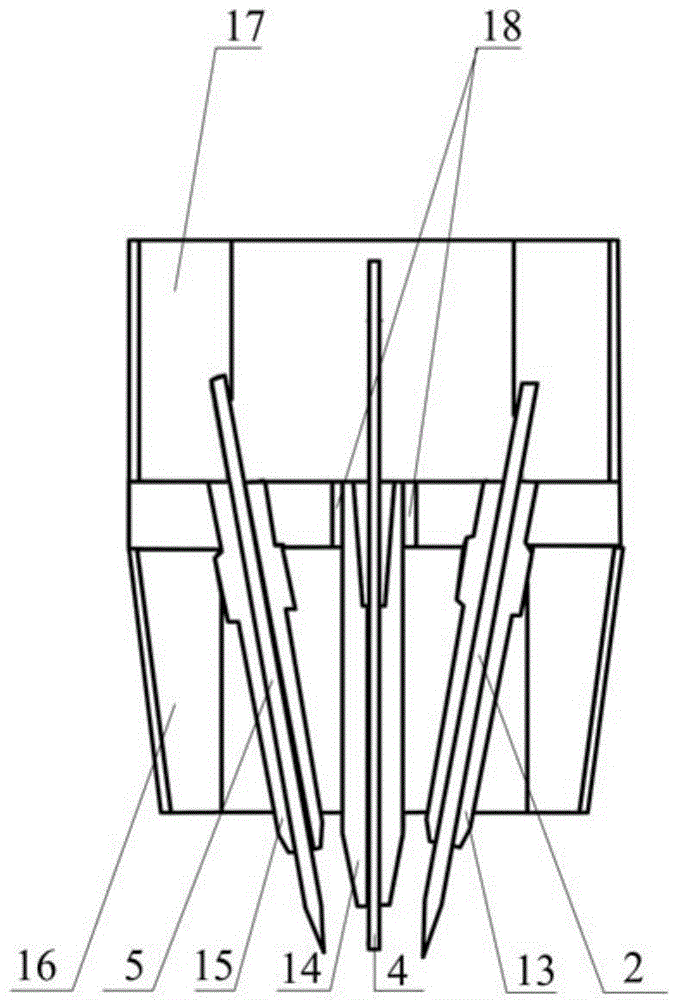

[0029] Figure 2 is a structure diagram of a center-filled wire-filled controllable shunt double tungsten coupled arc welding torch, which mainly consists of main tungsten electrode 2, welding wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com