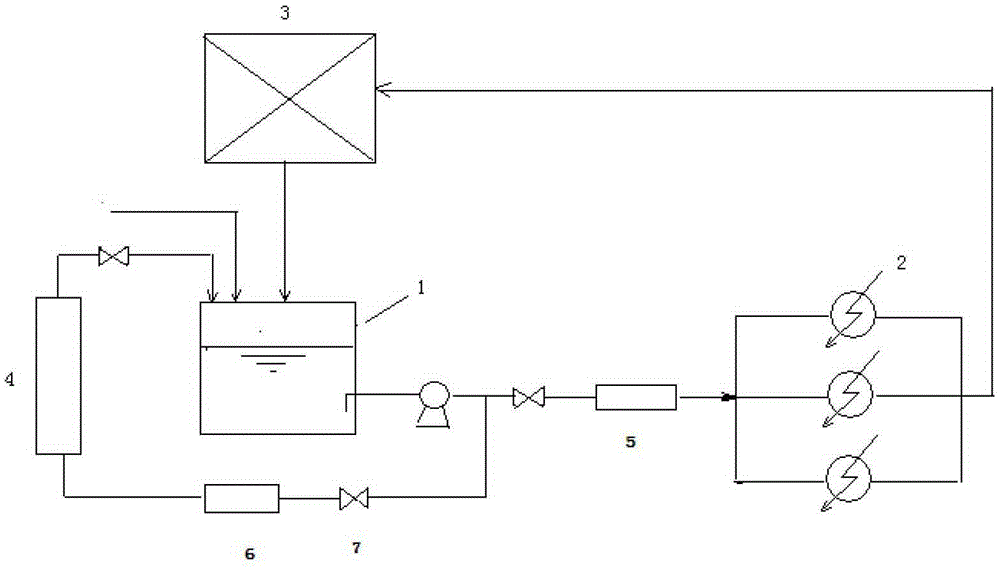

A cooling water circulation method

A cooling water and circulating cooling water technology, which is applied in the direction of sterilization/microdynamic water/sewage treatment, etc., can solve the problems of water pollution and large amount of fungicides, and achieve the effects of low dosage, simple method and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

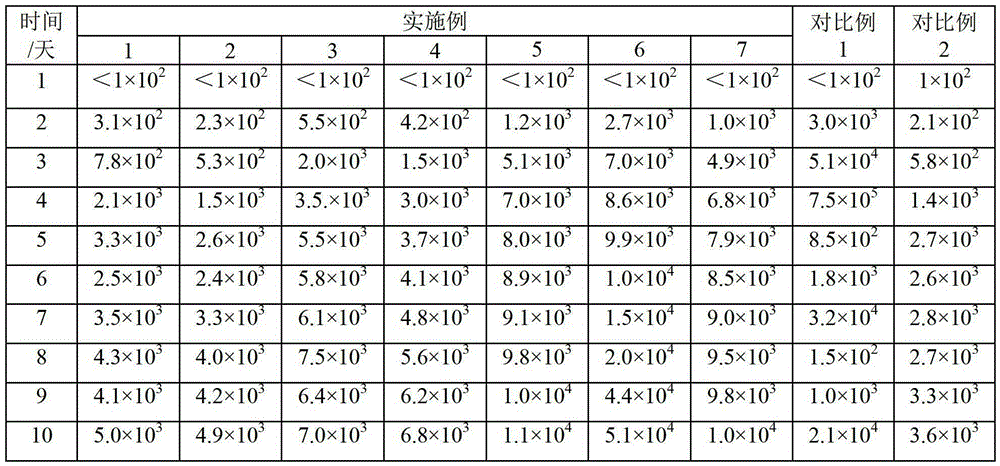

Examples

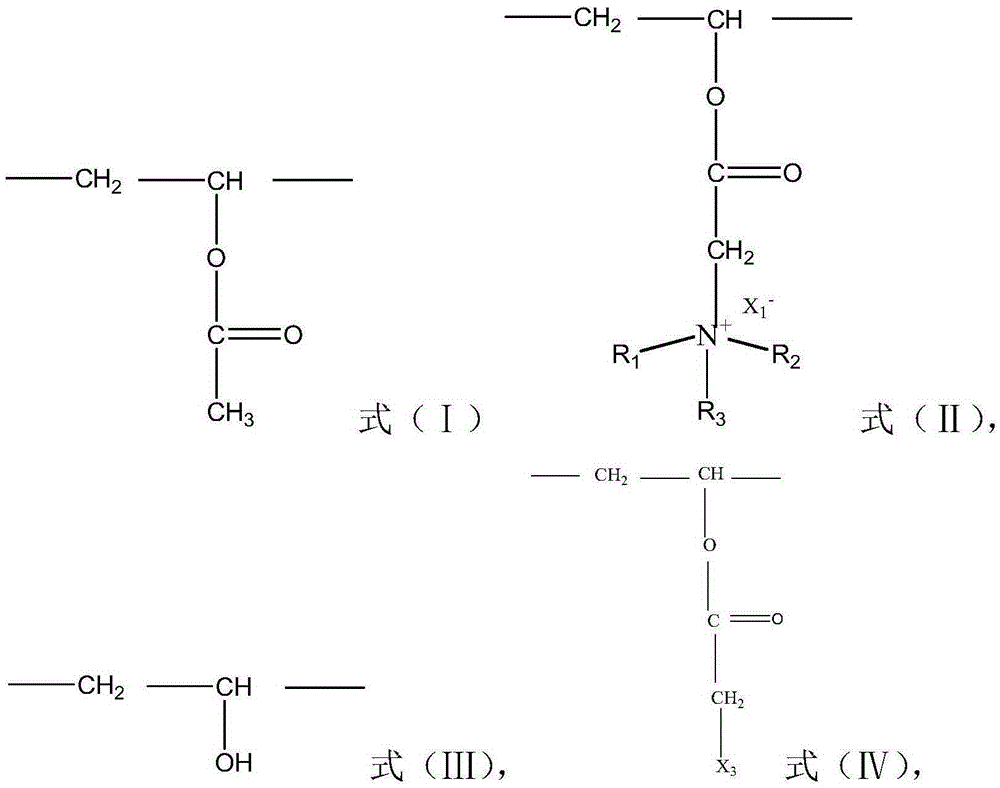

preparation example 1

[0046] The number average molecular weight of 10.0 grams is 1.2×10 4 Add polyvinyl alcohol (containing 12% by weight of acetyl groups) and 20.0 grams of chloroacetic anhydride to 30 grams of methyl ethyl ketone, and react at 80 ° C until the suspension of the entire reaction system becomes a clear solution , the reaction ends. With a concentration of 5% by weight sodium bicarbonate solution 100mL wash the mixture obtained by the reaction twice, the product is separated out, after filtration, the product obtained is added to acetone, then 35.0 grams of N,N-dimethylbenzylamine is added, heated to After 5 hours of reflux reaction, the acetone was evaporated, and then dried to obtain 55.1 g of polymer, which was designated as quaternary ammonium salt J1.

preparation example 2

[0048] The number average molecular weight of 5.0 grams is 2.0×10 4 Add polyvinyl alcohol (containing 12% by weight of acetyl groups) and 30.0 grams of bromoacetic anhydride to 30 grams of methyl ethyl ketone, and react at 80 ° C until the suspension of the entire reaction system becomes a clear solution , the reaction ends. With a concentration of 5% by weight sodium bicarbonate solution 100mL wash the mixture obtained by the reaction twice, the product is separated out, after filtration, the product obtained is added to acetone, then 25.0 grams of N,N-dimethylbutylamine is added, heated to After reflux for 5 hours, the acetone was evaporated, and then dried to obtain 53.2 g of polymer, which was designated as quaternary ammonium salt J2.

preparation example 3

[0050] The number average molecular weight of 5.0 grams is 1.8×10 4 Add polyvinyl alcohol (containing 12% by weight of acetyl groups) and 10.0 grams of chloroacetic anhydride to 20 grams of methyl ethyl ketone, and react at 80 ° C until the suspension of the entire reaction system becomes a clear solution , the reaction ends. After washing the reaction mixture twice with 100 mL of 5% by weight sodium bicarbonate solution, the product precipitated out. After filtration, the obtained product was added to acetone, and then 25.0 grams of triethylamine was added, heated to reflux for 5 hours and then evaporated. Acetone was removed, and then by drying, 51.8 g of polymer was obtained, which was designated as quaternary ammonium salt J3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com