APCVD furnace tube recover maintenance method

A furnace tube and organic matter technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of high cost, time-consuming, low production efficiency, etc., achieve low cost, high efficiency, and prevent impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

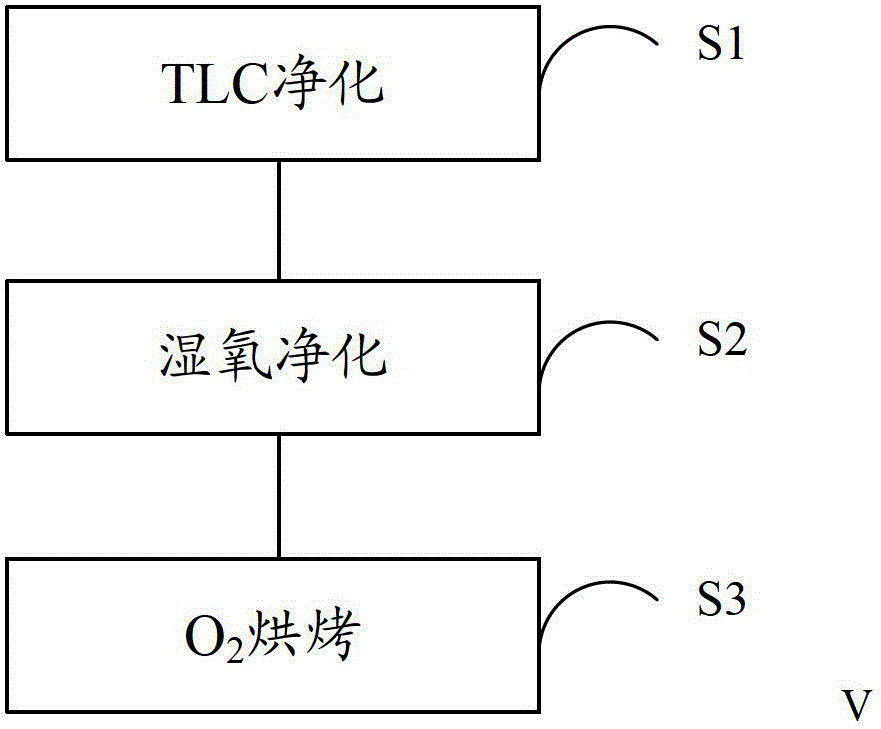

[0034] see image 3 , the present embodiment provides a method for repairing and maintaining an APCVD furnace tube, comprising the following steps:

[0035] Step 1, please refer to step S1, TLC purging (TLC purge), using N2, O2 combined with DCE (ie trans-dichloroethylene) to remove metal ions in the furnace tube and on the crystal boat located in the furnace tube. The temperature of the reaction is usually 1000-1150 degrees Celsius, and the thickness of the growth is about 1000 Angstroms (A). DCE is liquid at normal temperature. When using (i.e. when running a program), N2 enters the DCE storage bottle and then takes out the DCE to turn DCE into a gaseous state. Chloride ions from the DCE liquid enter the furnace tube in the form of a spray, and then react. Chloride ions mainly play a cleaning role, which can reduce the ion charge on the wafer, thereby reducing structural defects on the silicon surface. Since this step is a conventional technical means in the art, it will ...

Embodiment 2

[0045] see Figure 5 , the difference between the APCVD furnace tube recovery and maintenance method of this embodiment and the first embodiment is that: before step one, please refer to step S0, first perform O 2 Pre-baking to remove organic residues in the furnace tube and on the wafer boats in the furnace tube.

[0046] Preferably, in the above-mentioned APCVD furnace tube recovery maintenance method, O 2 During pre-baking, O 2 The gas flow rate is 10L ~ 20L / min, too high flow rate will affect the reaction effect, too high flow rate will affect the exhaust. The flow rate of 10L-20L / min combines the above two points to reach a better balance point. The reaction temperature is controlled at 1000°C-1150°C. A temperature that is too low will affect the reaction effect, and a temperature that is too high will affect the service life of the heater used to heat the temperature of the reaction chamber of the furnace tube. This temperature range better balances the above two fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com