A new type of floor tile and its manufacturing method

A new type of floor tile technology, applied in building structures, floors, buildings, etc., can solve the problems of consuming keel materials, complicated joint processing, and inability to guarantee quality, and achieve the effect of saving costs, reducing costs, and preventing liquid penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Although the present invention has been described with reference to specific embodiments, those skilled in the art will be able to make obvious modifications and modifications to the present invention after reading the above description without departing from the intent and essence of the present invention. The present invention intends to include such modifications and modifications within the scope of the claims.

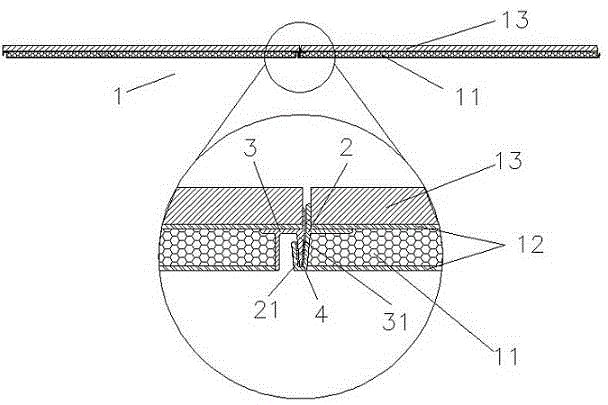

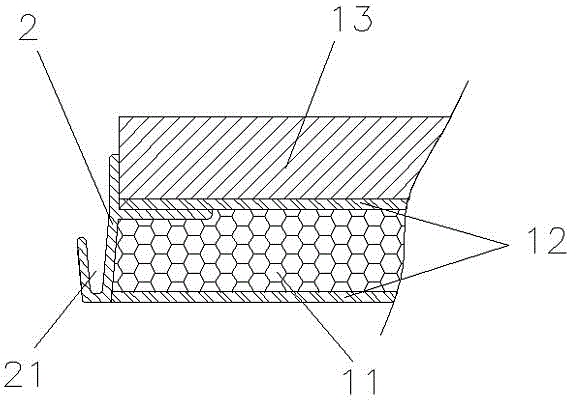

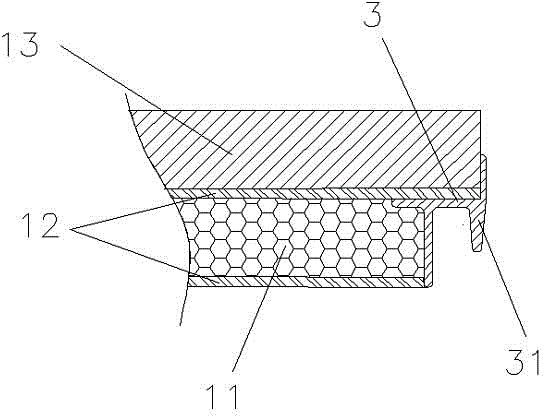

[0024] A new type of floor tile, such as Figure 1 to Figure 3 As shown, a brick body 1 is included, and the brick body 1 is made of a lightweight honeycomb composite material. The brick body 1 includes a honeycomb layer 11, a surface layer 12 and a surface layer 13, and the honeycomb layer 11 includes an aluminum honeycomb core material, At least one of paper honeycomb core material, plastic honeycomb core material and steel honeycomb core material, this embodiment preferably adopts aluminum honeycomb core material, which has the advantages of light weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com