Traceable synchronous measurement ruler-based mixed double-light source laser range finding device and method

A technology of laser ranging and synchronizing ruler, applied in measurement devices, radio wave measurement systems, and re-radiation, etc., can solve problems such as lack, improve real-time performance, overcome non-direct traceability, and improve measurement efficiency and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

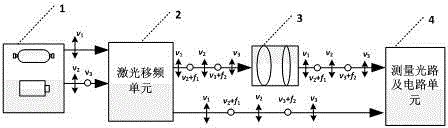

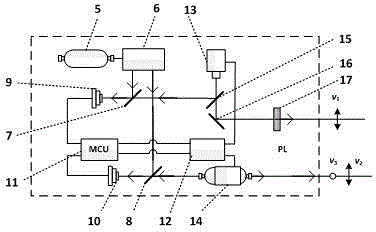

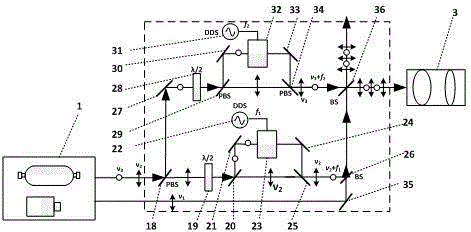

[0032] A hybrid dual light source laser distance measuring device based on a traceable synchronous measuring ruler, comprising a beam expanding collimating lens group 3, the device is composed of a measuring ruler generating unit 1, a laser frequency shifting unit 2, a beam expanding collimating lens group 3 and The measuring optical path and circuit unit 4 are composed, the laser output from the measuring ruler generation unit 1 is output to the input end of the laser frequency shifting unit 2, and the laser output from the laser frequency shifting unit 2 is output to the measuring optical path and circuit through the beam expanding collimating lens group 3 One input end of unit 4, the other laser output from the laser frequency shifting unit 2 is directly input to the other input end of the measurement optical path and circuit unit 4;

[0033] The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com