Space Debris Removal System Based on Split Multi-telescope Form of Laser Beam Combination

A space debris and laser beam combining technology, applied in the space field, can solve problems such as thermal deformation of components, achieve the effects of improving the impact, weakening the thermal deformation of the mirror surface, and improving the cleaning effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

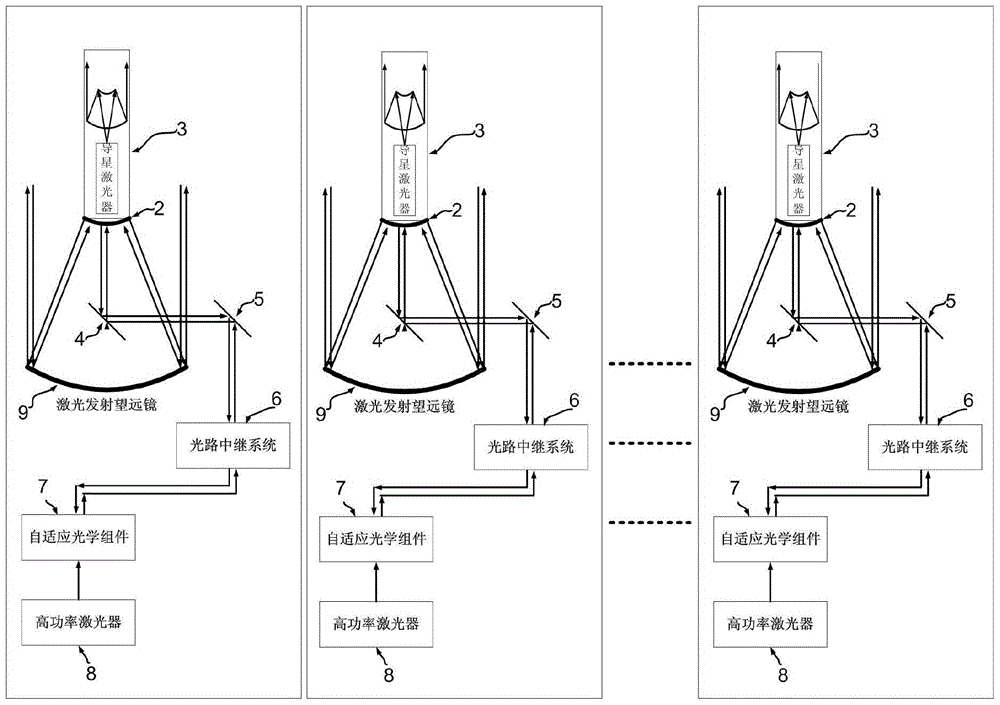

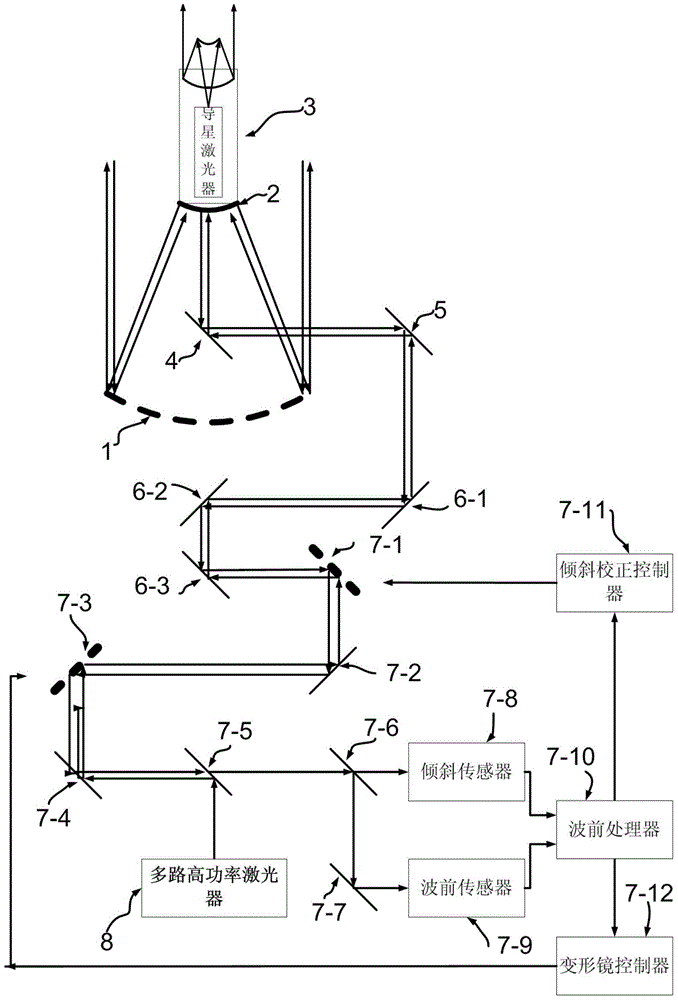

[0015] Specific implementation mode 1. Combination Figure 1 to Figure 5 Describe this embodiment, based on the laser beam combining space debris removal system in the form of separate multi-telescopes, for the form of separate multi-telescopes, each telescope system has a set of corresponding support and target tracking systems. Each telescope system is mainly composed of a laser emitting telescope, a laser guide unit 3, an optical path relay system 6, an adaptive optics component 7 and a high-power laser emitter 8. Wherein the main optical system composed of monolithic primary mirror 1 and secondary mirror 2 is installed on a set of support and target tracking system to form a laser emitting telescope; the laser guide unit 3 is installed on the back of secondary mirror 2 to emit a beam of laser light to At an altitude of about 90 kilometers, a laser guide star is formed, and the telescope receives the light of the guide star. After passing through the optical path relay syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com