Aerated block cutting waste recycling system

A technology of waste recycling and aerated blocks, which is applied in the directions of ingredient storage, sales of raw material supply devices, manufacturing tools, etc. It can solve the problems that affect production efficiency and the recycling tank has no circulating water circulation, so as to improve work efficiency and speed up material discharge speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

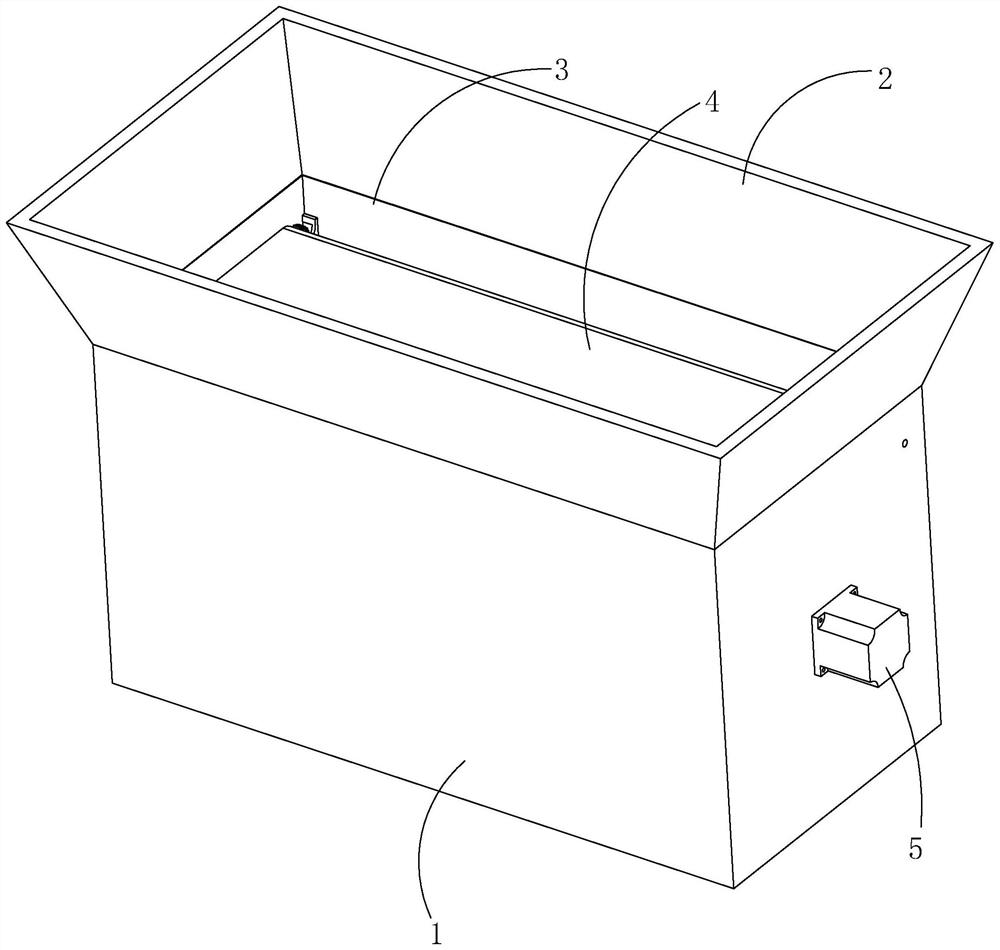

[0035] refer to figure 1 , is an aerated block cutting waste recycling system disclosed in the present invention, comprising a stirring box 1 arranged below the cutting machine (not shown in the figure), and a feeding hole facing the cutting machine is opened on the stirring box 1 ( Not shown in the figure), the opening end of the mixing box 1 is fixedly connected with the storage bin 2, the storage bin 2 opens in the direction of the cutting machine, and the storage bin 2 is opened in the direction of the feeding hole to communicate with the feeding hole The blanking hole 3, the blanking hole 3 overlaps with the feeding hole, and the blanking hole 3 is provided with a baffle plate 4 for passing through the blanking hole 3.

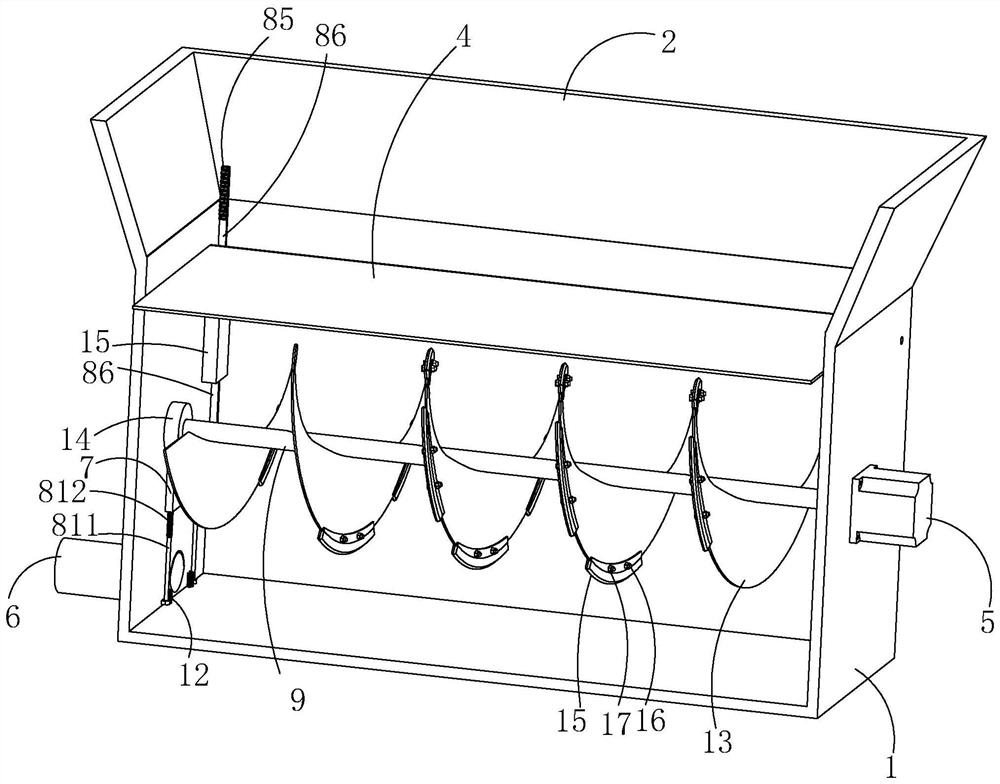

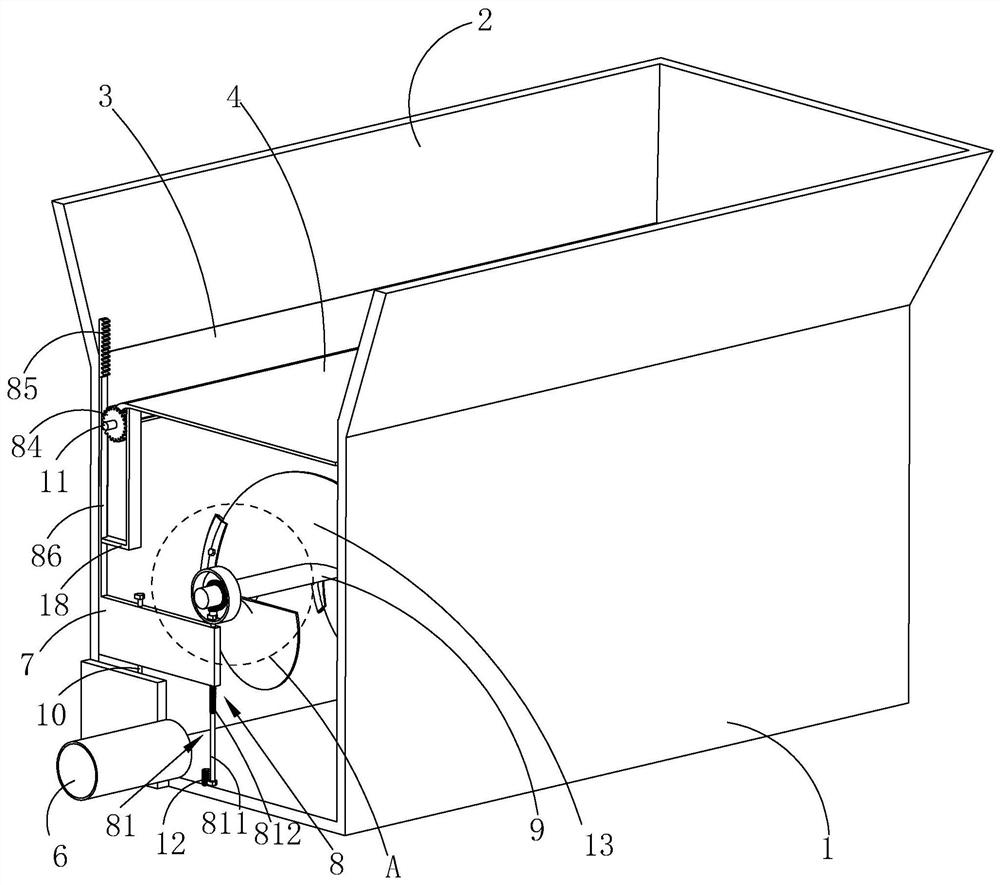

[0036] see figure 2 and image 3 , the mixing box 1 is in the shape of a cuboid, and the stirring box 1 is rotatably connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com