Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as large gate-source parasitic capacitance and parasitic on-resistance, and reduce parasitic resistance effects and parasitic on-resistance. Capacitance effect, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0062] Furthermore, repeated reference numerals or designations may be used in different embodiments. These repetitions are merely for the sake of simplicity and clarity of describing the present invention, and do not imply any relationship between the different embodiments or structures discussed.

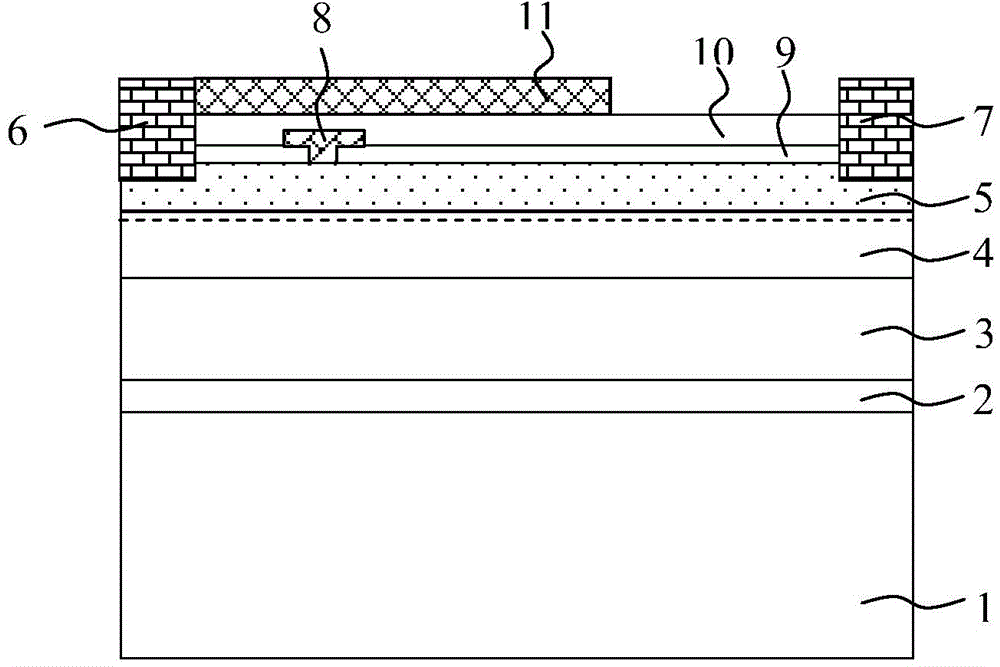

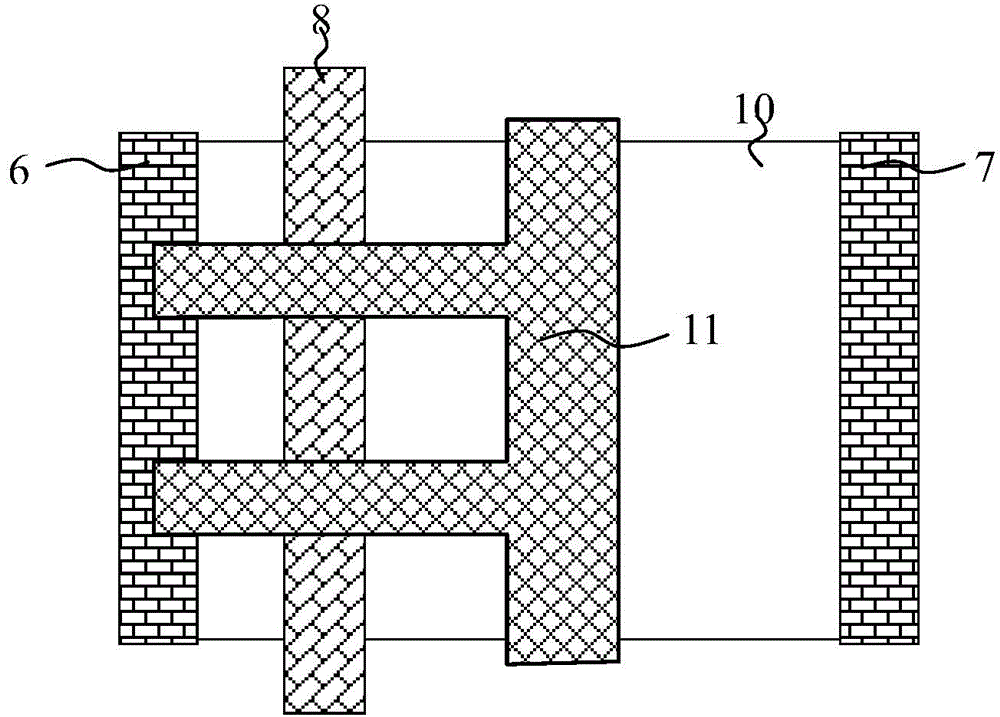

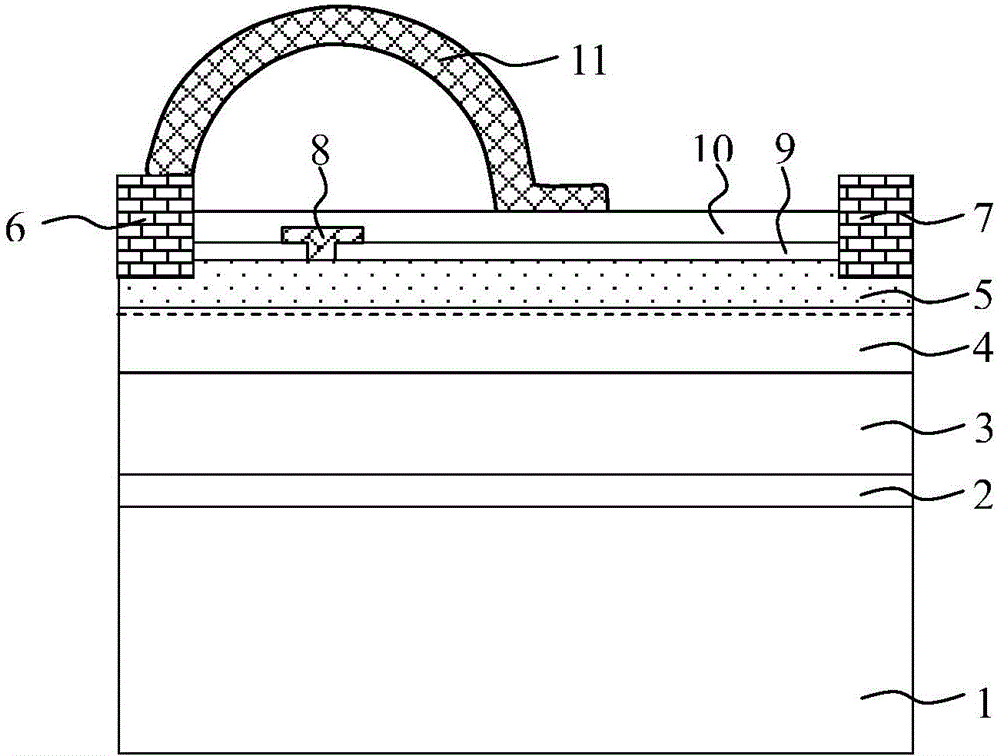

[0063] Figure 3A is a schematic cross-sectional view of a semiconductor device with a segmented air-isolated source-field plate structure in the first embodiment of the present invention, Figure 3B Its plan view.

[0064] like Figure 3A As shown, the semiconductor device includes:

[0065] Substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com