Preparation method of composite nanometer piezoelectric generator

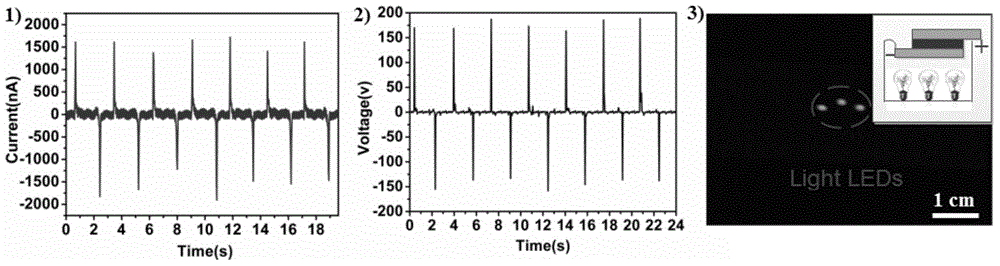

A generator and piezoelectric technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, generator/motor, material selection for piezoelectric devices or electrostrictive devices, etc., can solve the output of nano-film Not high, polydimethylsiloxane has no piezoelectric performance and other problems, and achieves the effects of low price, uniform external force, and high output short-circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

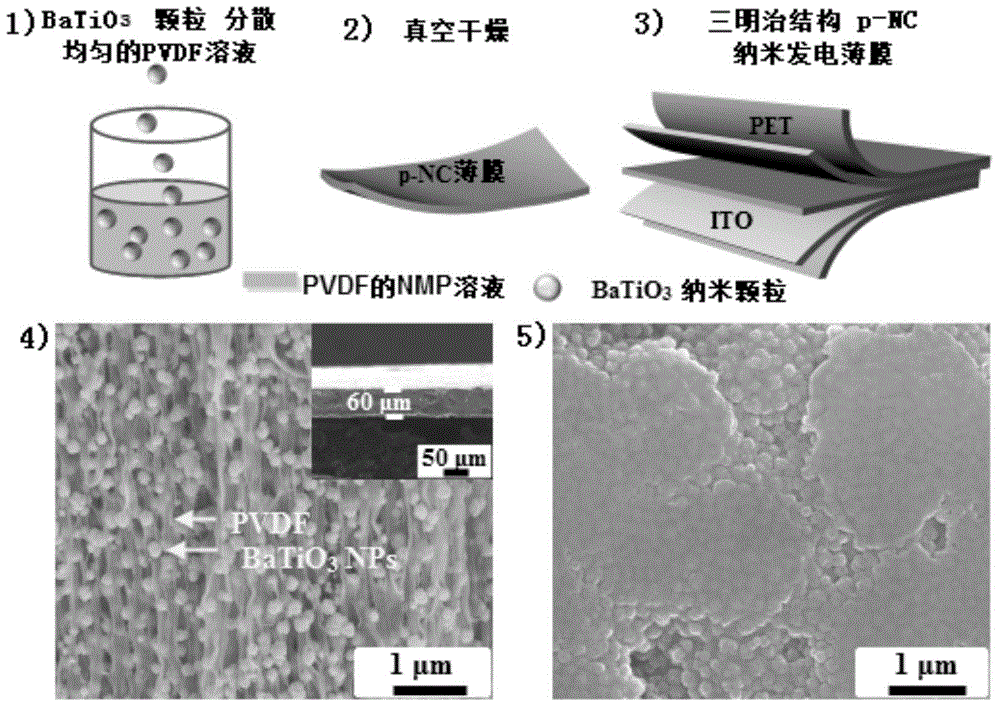

[0020] Embodiment 1: Preparation of PVDF / barium titanate nanoparticle composite nanofilm

[0021] (1) Preparation of PVDF organic solvent: Weigh 3g of PVDF particles with a balance and put it into a clean round-bottomed flask, weigh 30ml of nitrogen methylpyrrolidone (NMP) organic solvent with a graduated cylinder and pour it into the round-bottomed flask, and put it in the flask. rotor, place the flask in a magnetic stirring water bath, adjust the temperature to 45°C, and rotate the speed to 3000r / min. Stirring was continued for 12 hours to obtain a fully dissolved PVDF organic solvent. preparation process such as Picture 1-1 to 1-3.

[0022](2) Substrate cleaning and preparation of PVDF / barium titanate nanoparticle mixed solution: After ultrasonically cleaning the glass slide substrate with acetone, ethanol, isopropanol, and deionized water, dry it with nitrogen gas; measure 3ml of the PVDF organic solution obtained above Put it into a clean beaker, weigh 0.7g of bariu...

Embodiment approach 2

[0025] Embodiment 2: Preparation of PVDF / lithium niobate nanoparticle composite nanofilm

[0026] (1) Prepare PVDF organic solvent as in Example 1.

[0027] (2) Substrate cleaning and preparation of PVDF / lithium niobate nanoparticle mixed solution: substrate cleaning, measure 3ml of the PVDF organic solution obtained above into a cleaned beaker, weigh 0.3g of lithium niobate nanoparticles into the beaker with a balance In the process, seal the mouth of the beaker with a parafilm, put the beaker in an ultrasonic machine, and keep stirring for 10-30min, and stir evenly.

[0028] (3) Obtain the composite nano film: put the washed glass slide on a very flat petri dish, drop the obtained mixed solution on the glass slide with a dropper, and spread the solution on the glass slide. Put the petri dish into a vacuum drying oven, evacuate, adjust the temperature to 55° C., and vacuum dry for 1 hour. Take out the petri dish, and carefully peel off the film on the glass slide with twe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com