Sulfur positive electrode of lithium sulfur battery and preparation method

A lithium-sulfur battery and sulfur cathode technology, which is applied in the field of sulfur-based composite materials containing biomass activated carbon and its preparation, can solve the problems of low conductivity of elemental sulfur, hinder ion exchange, loss of active materials, etc., and improve the Coulombic efficiency. and cycle life, reduced shuttle effect, good effect of coating sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

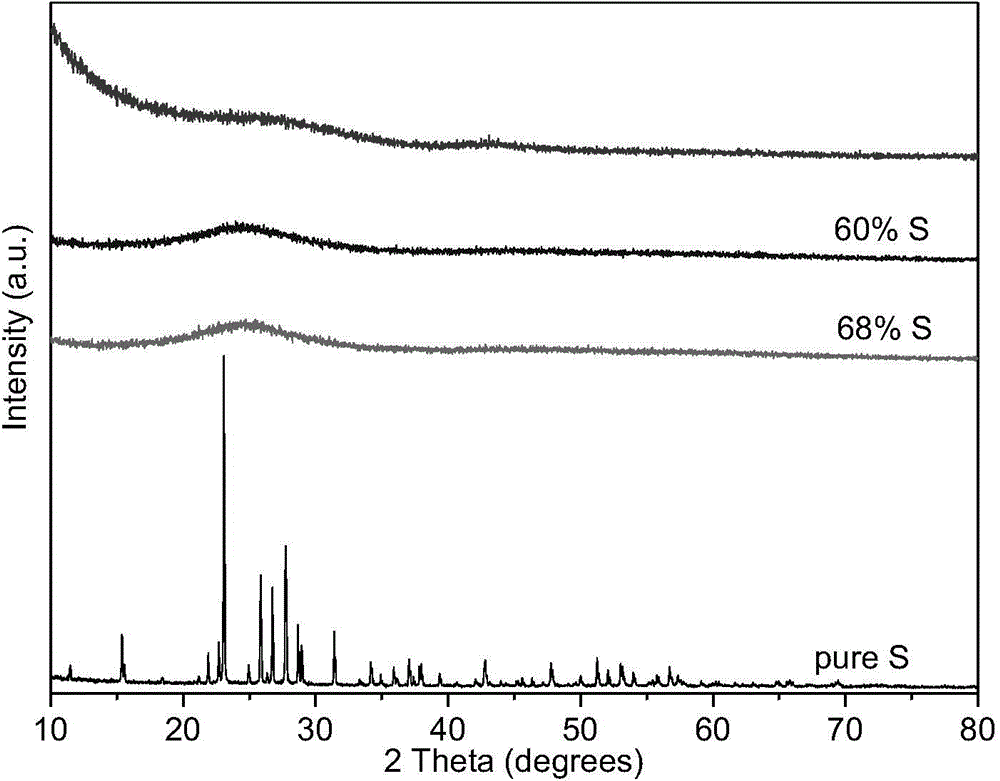

Method used

Image

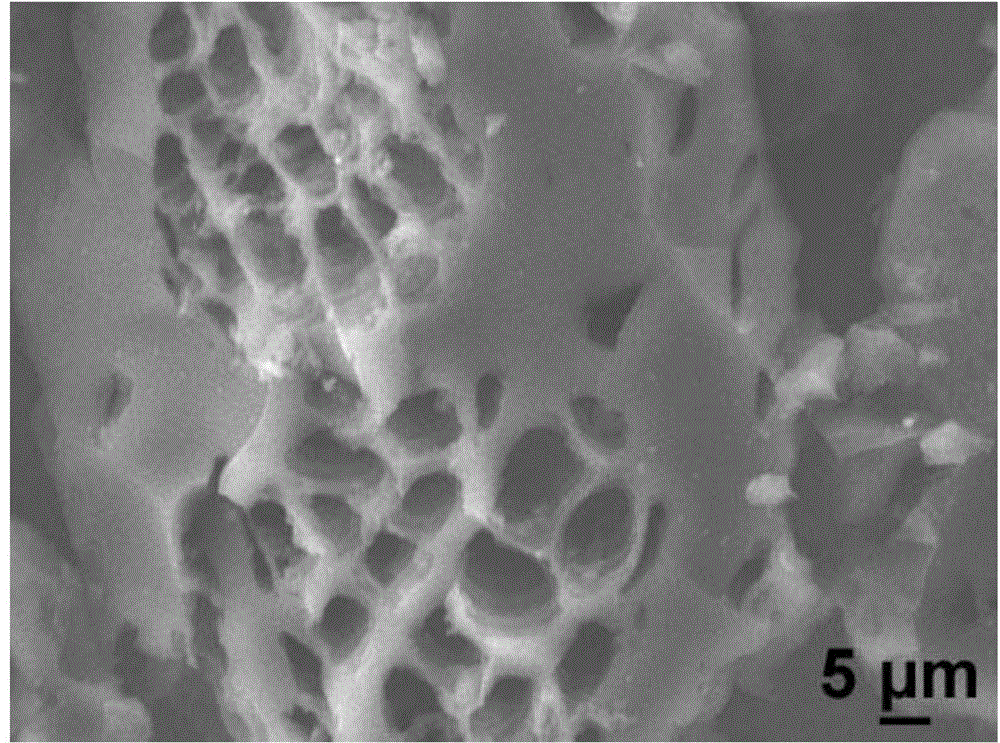

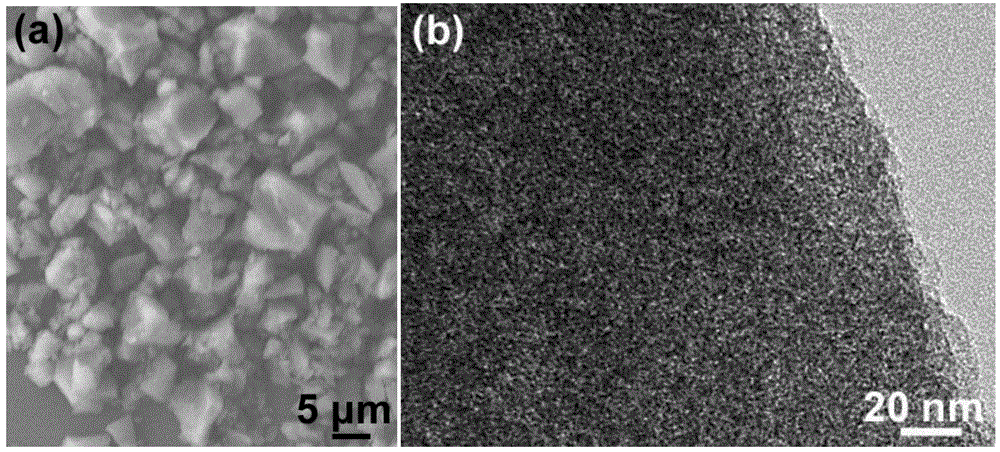

Examples

Embodiment 1

[0031] 1) Take a certain amount of lychee shells, wash them with water, dry them, and crush them into pieces;

[0032] 2) In a tube furnace, protected by argon, pre-carbonized at 500°C for 2 hours to obtain pyrolyzed litchi shells;

[0033] 3) Take it out and weigh it, mix it with KOH at a mass ratio of 1:4, dissolve KOH with water, stir the mixture fully with a magnet, and let it stand for 1 hour to ensure that the KOH solution completely penetrates into the pyrolyzed litchi shell;

[0034] 4) Then dry the mixture at 100°C with a blast drying oven, and wait for the water to evaporate completely;

[0035] 5) In the tube furnace, protected by argon, and annealed at 900°C for 1 hour to make it completely carbonized;

[0036] 6) After cooling, the sample was washed with 1M HCl solution and deionized water by suction filtration until the pH value reached 7;

[0037] 7) The sample is then dried in a blast drying oven at 80° C. to obtain a biomass activated carbon material.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com