Powder coating metal overlay decoration plate and manufacturing method thereof

A powder coating and metal panel technology, applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve the problems of affecting the appearance decoration effect, difficult to meet the aesthetic requirements, high moisture content of wood, etc., and achieve good promotion and application Value, reasonable production method, good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

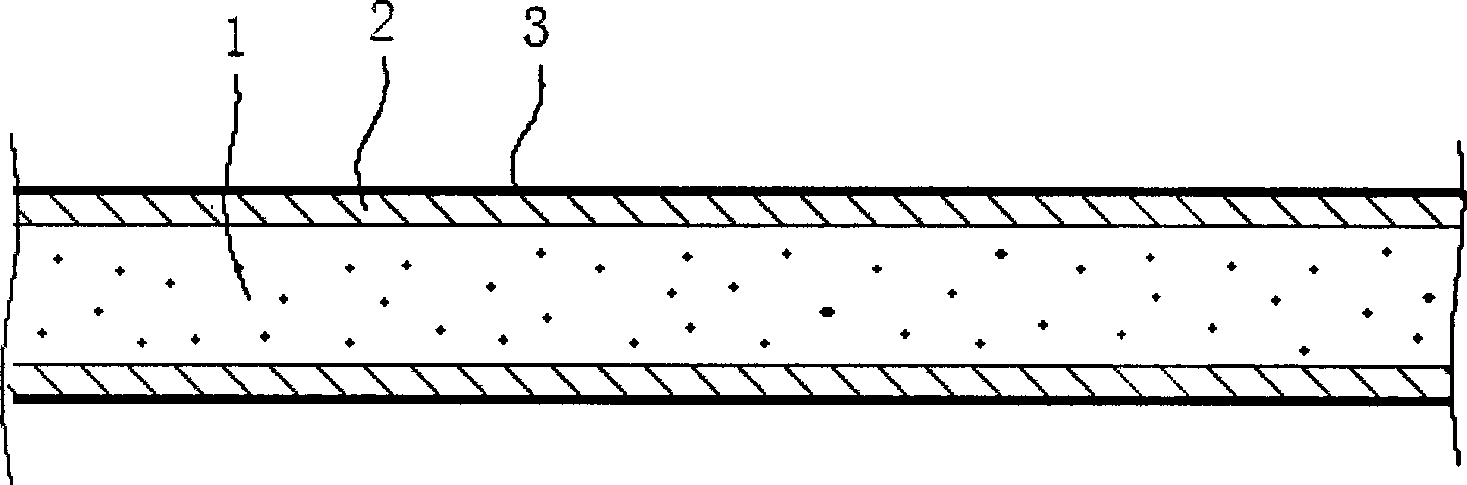

[0025] see figure 1 , the powder coating metal veneer decorative board of the present invention comprises a man-made board or a natural board substrate 1, and a metal panel 2 is covered by a strong adhesive on both sides of the man-made board or natural board substrate 1, and the metal panel 2 The surface is sprayed with a thermosetting powder coating layer 3.

Embodiment 2

[0027] see figure 2 In this embodiment, on the basis of Embodiment 1, a decorative layer 4 is thermally transferred on the powder coating layer.

Embodiment 3

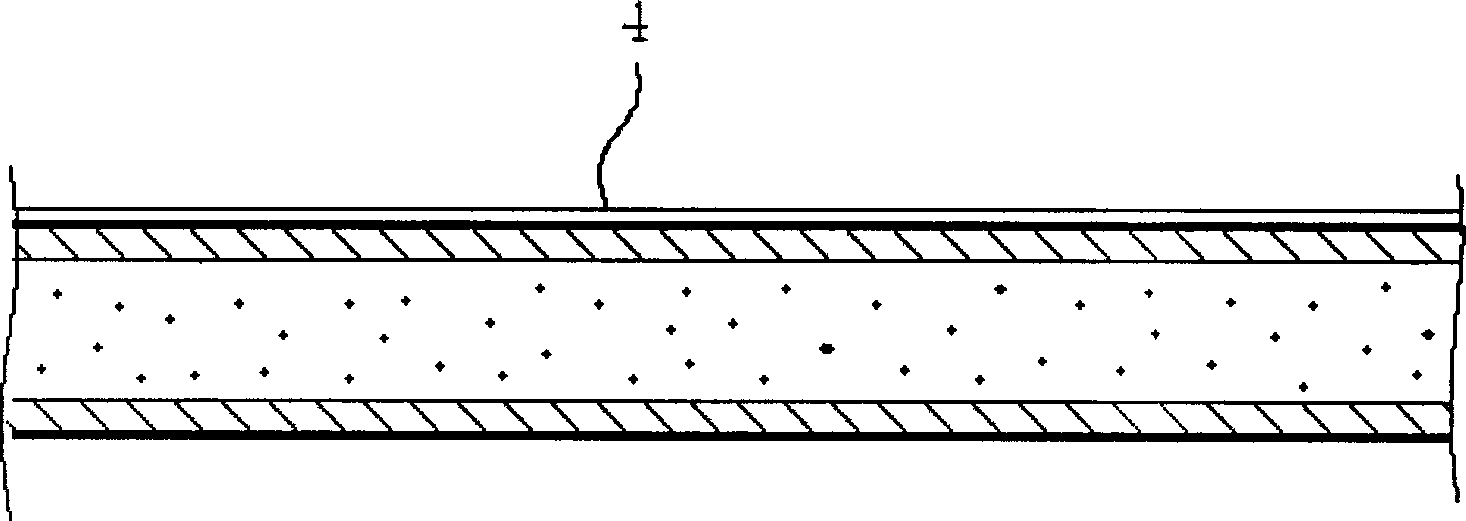

[0029] see image 3 In this embodiment, on the basis of Example 2, a flexible material filling layer 5 is provided between the metal panel and the wood-based panel or natural panel base material, which is used to fill the pits on the surface of the base material, so that the metal panel is more Good adhesion to the substrate.

[0030] The base material of the artificial board is one of low, medium and high density fiberboard, particle board, wood board and plywood.

[0031] The metal panel is one of aluminum plate, stainless steel plate, steel plate, copper plate and alloy plate.

[0032] The flexible material is a natural or man-made fiber or a composite material.

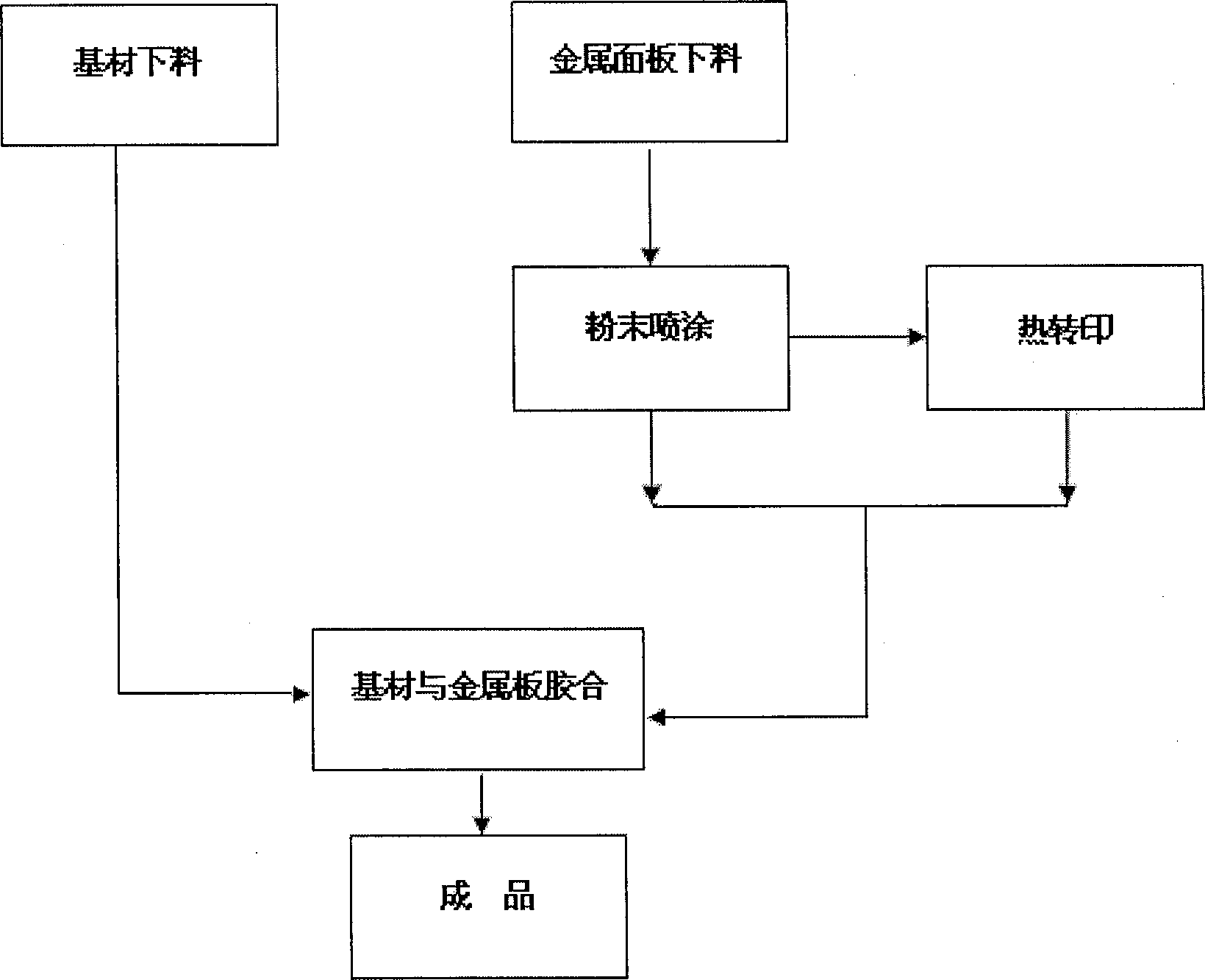

[0033] The preparation method of powder coating metal veneer decorative board of the present invention, as Figure 4 shown, including the following steps:

[0034] 1. Blanking: Cutting the wood-based panel or natural board substrate and the metal panel separately according to the size requirements;

[0035] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com