Carrier for microbial purification of water body and manufacturing method of carrier

A microbial purification and carrier technology, applied in the field of microbial purification carrier and its production, water microbial purification carrier and its production field, can solve the problems of poor biocompatibility and mass transfer, difficult recycling, complicated operation, etc. Achieve the effects of increasing the amount of biofilm, high tensile strength, and expanding the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

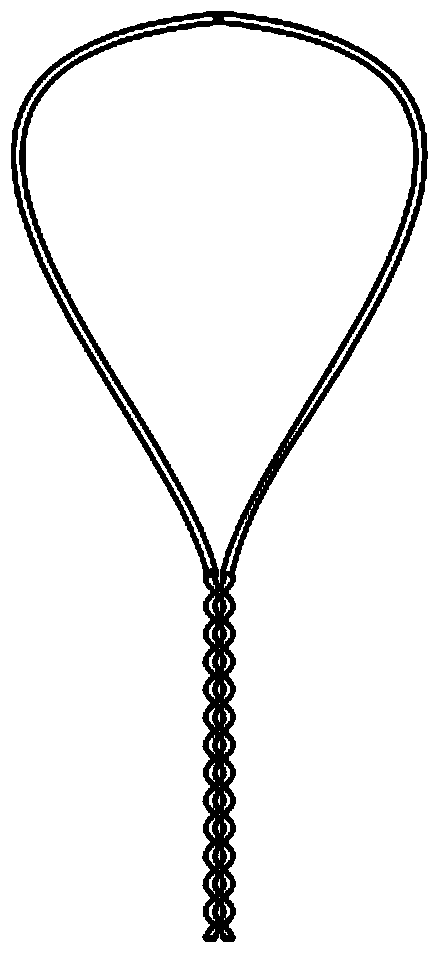

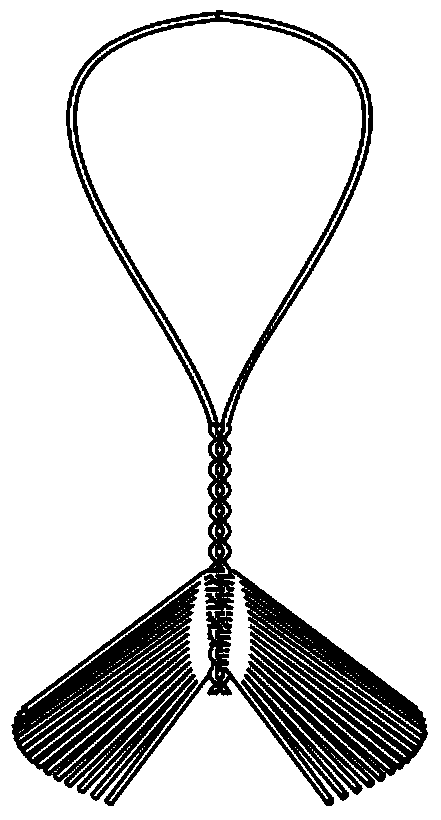

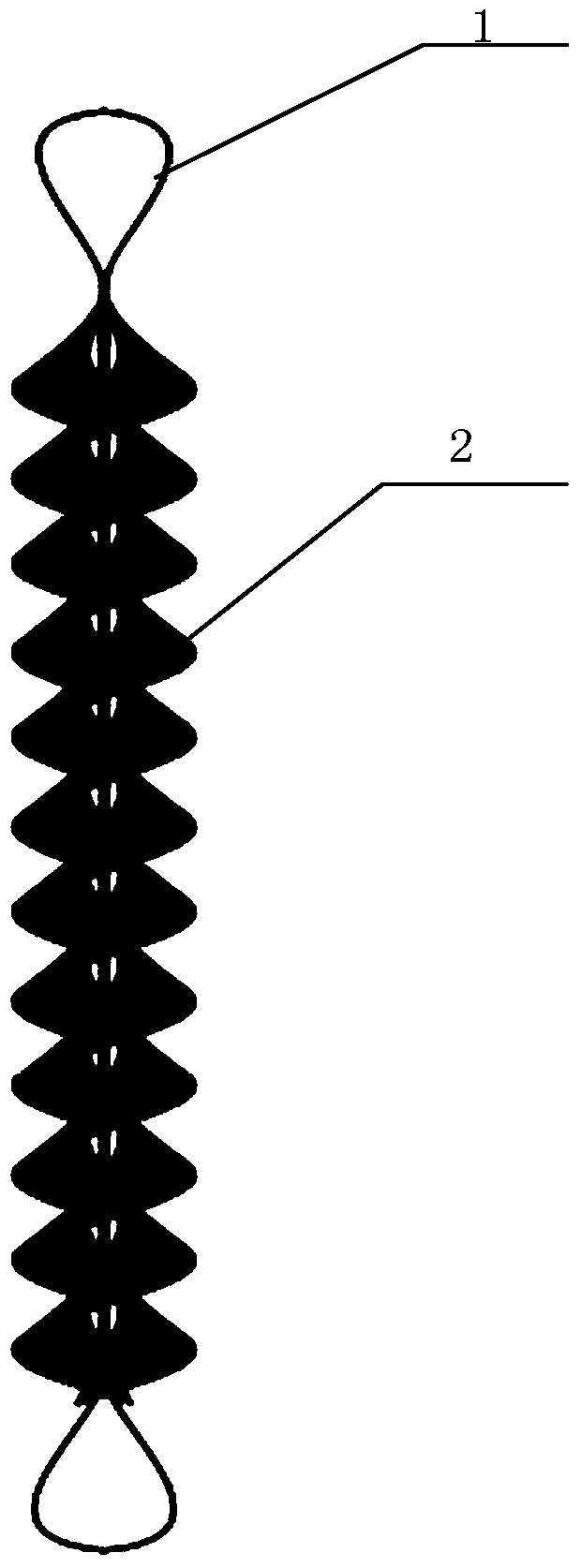

[0021] Cut basalt fiber bundles with a length of 20cm and 1000 basalt fibers in each bundle, and arrange them in a spiral order with a size of 6mm 2 on the insulation layer of the single-core cable. The production method is as follows: the basalt fiber bundle is sandwiched in the middle of the double-folded single-core cable through manual twisting until the length of the unit carrier bundle is 50cm.

Embodiment example 2

[0023] Cut basalt fiber bundles with a length of 25cm and 800 basalt fibers each, and arrange them in a spiral order with a size of 4mm 2 on the insulation layer of the single-core cable. The production method is as follows: the basalt fiber bundle is sandwiched in the middle of the double-folded single-core cable through manual twisting, until the length of the unit carrier bundle is 60cm.

Embodiment example 3

[0025] Cut basalt fiber bundles with a length of 30cm and 600 basalt fibers each, and arrange them in a spiral order with a size of 2.5mm 2 on the insulation layer of the single-core cable. The production method is as follows: the basalt fiber bundle is sandwiched in the middle of the double-folded single-core cable through manual twisting, until the length of the unit carrier bundle is 70cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com