Layer-by-layer electroosmosis method and device for dewatering energy-containing sludge

A technology of sludge dehydration and electroosmosis, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems that the moisture content of sludge cannot be very balanced, affect the effect of electroosmosis, and the operation process is complicated, etc., to achieve favorable Promote, improve production efficiency, save the effect of crushing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

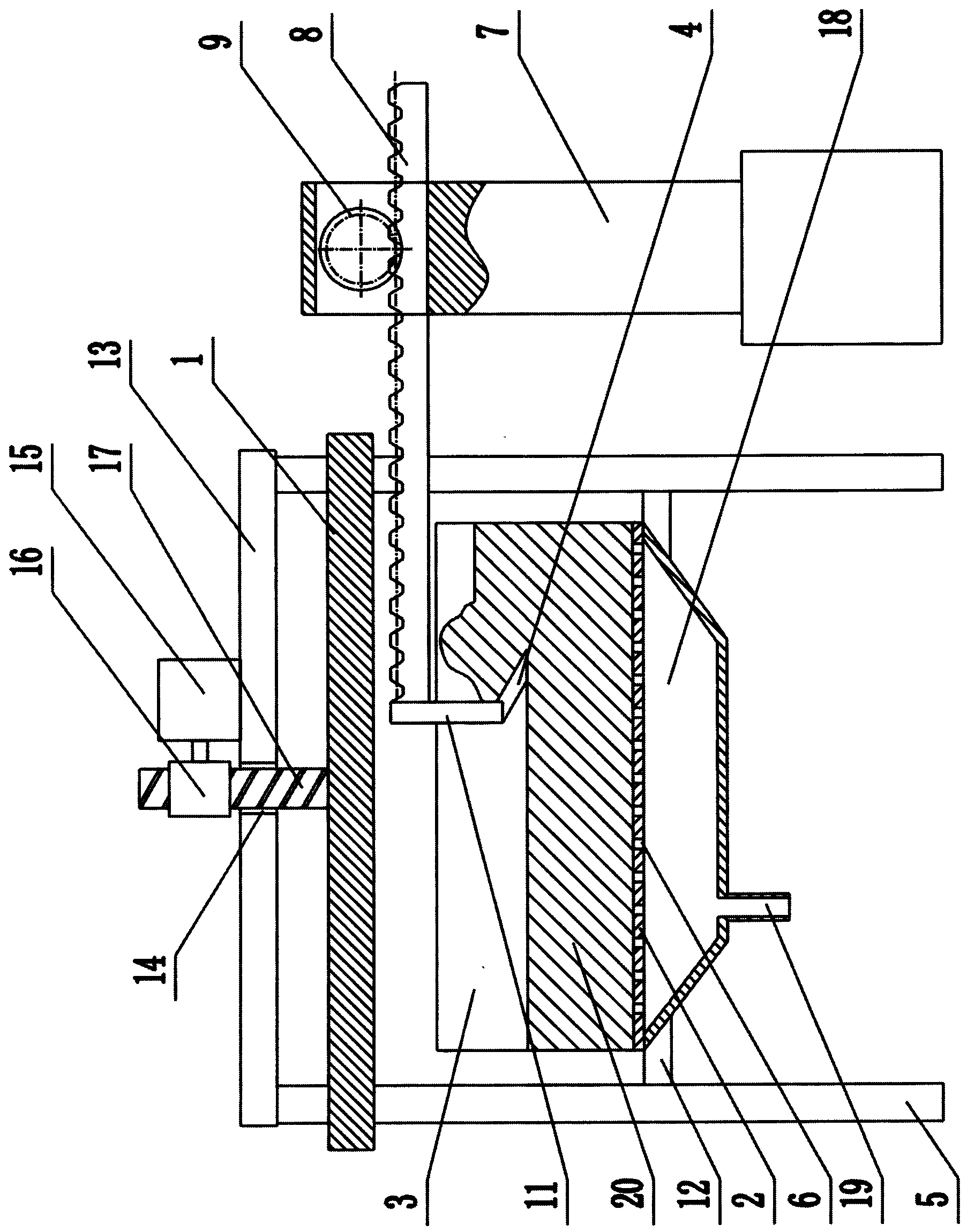

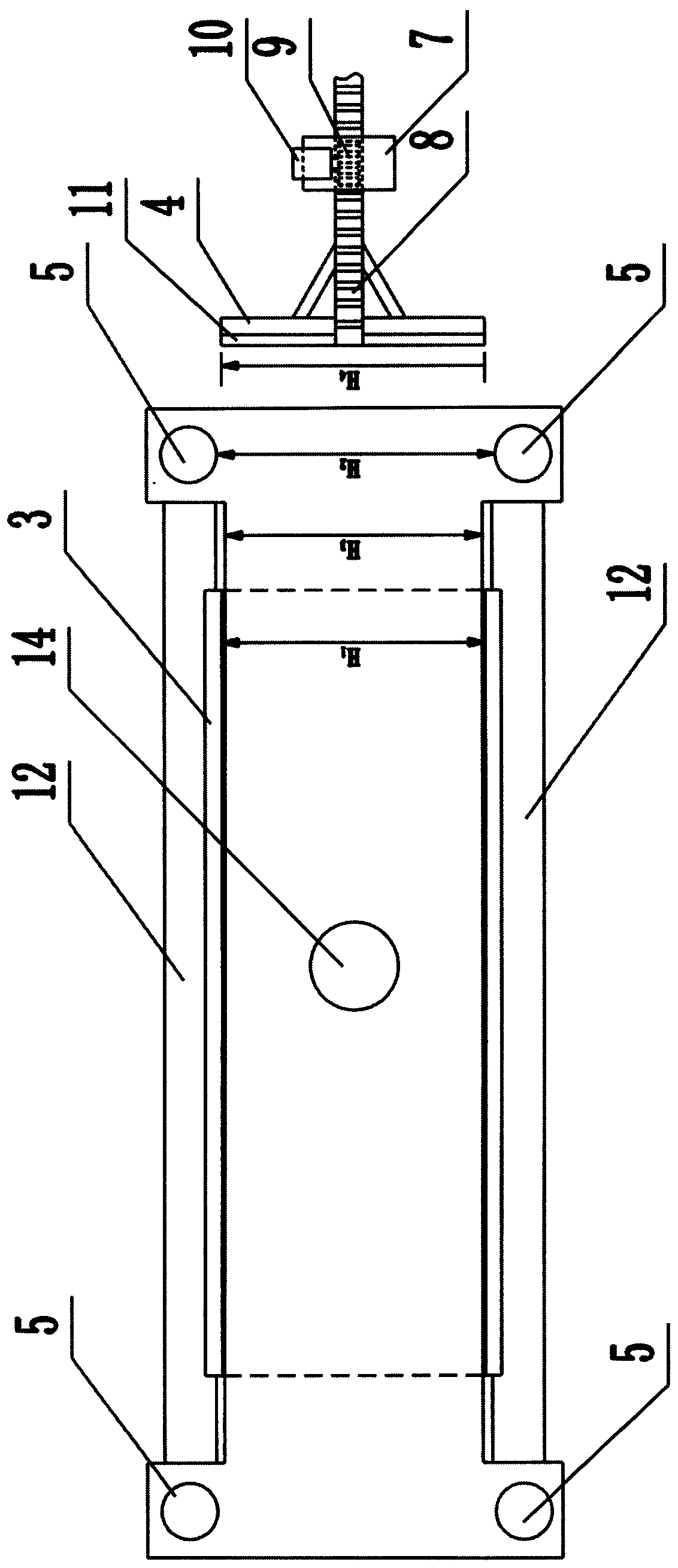

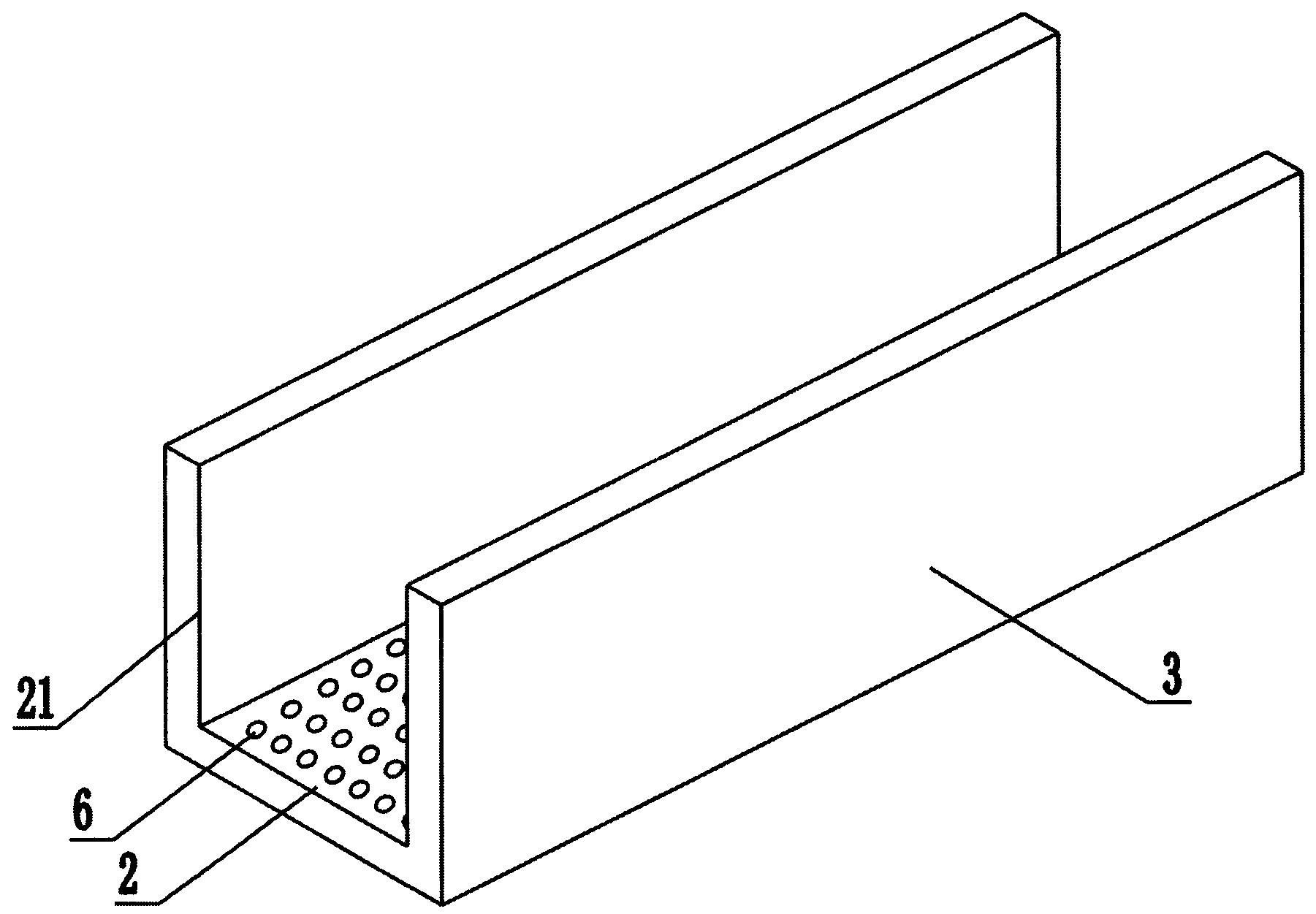

[0034] As an embodiment of the electroosmotic method of energetic sludge dewatering described in the present invention, such as figure 1 , figure 2 and image 3 As shown, it includes an anode 1, a cathode 2, a sludge tank 3, a scraper 4 and four columns 5, and the columns 5 are arranged around the sludge tank 3, and the anode 1 is arranged above the sludge tank 3, And the column 5 passes through the anode 1, the anode 1 moves up and down along the column 5, the cathode 2 is arranged on the bottom surface of the sludge tank 3, and the cathode 2 is provided with a water seepage hole 6. One side of the sludge tank 3 is provided with a sludge feed port 21, and the other side is provided with a support column 7, and the support column 7 is provided with a scraper feeding device, and the scraper 4 is arranged on the on the scraper feeder.

[0035] In this embodiment, the scraper feeding device includes a rack 8, a gear 9 and a first motor 10, the rack 8 is arranged on the support ...

Embodiment 2

[0049] As an embodiment of the electroosmotic method for dewatering energetic sludge in the present invention, the difference from Embodiment 1 is that in this embodiment, the diameter of the seepage holes 6 is 3 millimeters, and the hole distance is 10 millimeters; The anode 1 moves down to the upper surface of the sludge 20 to perform electroosmosis on the sludge 20. The initial voltage setting value of the electroosmosis is 40 volts. As the electroosmosis proceeds, the current decreases continuously. When the current is reduced to 10% of the initial current, the electroosmosis is stopped, and the electroosmosis takes 5 minutes, and the upper layer of the sludge 20 becomes dry and cracked, and the water content decreases; The scraper 4 is moved to 20 mm below the upper surface of the sludge 20, and the scraper 4 is moved to scrape off a layer of sludge 20 close to the anode, and the moisture content of the treated sludge 20 is reduced from higher than 80% to about 50% %.

...

Embodiment 3

[0052] As an embodiment of the electroosmotic method for dewatering energetic sludge in the present invention, the difference from Embodiment 1 is that in this embodiment, the diameter of the seepage holes 6 is 5 mm, and the hole distance is 20 mm; The anode 1 moves down to the upper surface of the sludge 20 to perform electroosmosis on the sludge 20. The initial voltage setting value of the electroosmosis is 20 volts. As the electroosmosis proceeds, the current decreases continuously. When the current is reduced to 10% of the initial current, the electroosmosis is stopped. The electroosmosis takes 10 minutes, and the upper layer of the sludge 20 becomes dry and cracked, and the water content decreases; The scraper 4 is moved to 100 mm below the upper surface of the sludge 20, and the scraper 4 is moved to scrape off a layer of sludge 20 close to the anode, and the moisture content of the treated sludge 20 is reduced from higher than 80% to about 70% %.

[0053] In this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com