Method for reinforcing carbonate rock stone historical relics

A technology of stone cultural relics and carbonate rocks, which is applied in the field of reinforcement of loose calcium carbonate rocks, can solve problems such as different capillary forces, and achieve the effects of good compatibility, improved stain resistance, and improved stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

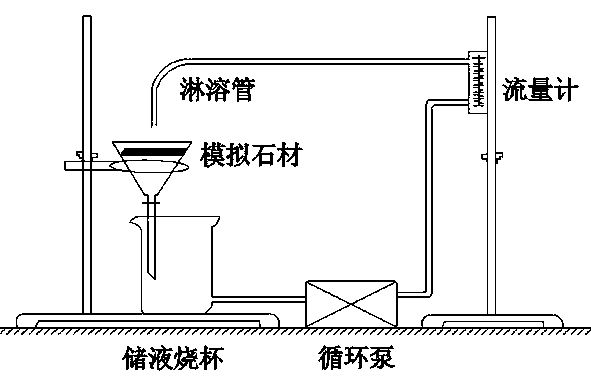

Method used

Image

Examples

Embodiment 1

[0020] (1) Clean the rock surface with deionized water;

[0021] (2) Adjust the pH to 3.8 with tartaric acid and ammonia water, and the concentration of tartaric acid is 0.15mol L -1 Ammonium tartrate solution to treat the rock surface to form a calcium tartrate transition layer on the rock surface, thereby bringing functional hydroxyl groups on the rock surface;

[0022] (3) Then the surface of the stone is treated with modified tetraethyl silicate sol, and a reinforced protective layer with silica as the main component is formed in the pores of the loose rock, and these protective layers are connected with calcium carbonate through hydroxyl groups;

[0023] (4) Aging at room temperature for 30 days.

[0024] Preparation of the modified tetraethyl orthosilicate sol described in step (3): at room temperature, first mix ethyl orthosilicate and ethanol, stir for 10 minutes, add deionized water, and then ultrasonicate for 10 minutes under stirring conditions, and then Add polyd...

Embodiment 2

[0030] (1) Clean the rock surface with deionized water.

[0031] (2) Adjust the pH to 4.0 with tartaric acid and ammonia water, and the concentration of tartaric acid is 0.17mol L -1 The ammonium tartrate solution is used to treat the rock surface to form a calcium tartrate conversion layer on the rock surface, so that the rock surface can be equipped with functional hydroxyl groups.

[0032] (3) Then the surface of the stone is treated with modified tetraethyl silicate sol, and a reinforced protective layer with silica as the main component is formed in the pores of the loose rock, and these protective layers are connected with calcium carbonate through hydroxyl groups.

[0033] (4) Aging at room temperature for 30 days.

[0034] Preparation of the modified tetraethyl orthosilicate sol described in step (3): first, mix ethyl orthosilicate and isopropanol, stir for 10 minutes, add deionized water, and then ultrasonicate for 10 minutes while stirring, then vigorously Add hydr...

Embodiment 3

[0037] (1) Clean the rock surface with deionized water.

[0038] (2) Adjust the pH to 4.0 with tartaric acid and ammonia water, and the concentration of tartaric acid is 0.17mol L -1 The ammonium tartrate solution is used to treat the rock surface to form a calcium tartrate conversion layer on the rock surface, so that the rock surface can be equipped with functional hydroxyl groups.

[0039](3) Then the surface of the stone is treated with modified tetraethyl silicate sol, and a reinforced protective layer with silica as the main component is formed in the pores of the loose rock, and these protective layers are connected with calcium carbonate through hydroxyl groups.

[0040] (4) Aging at room temperature for 30 days.

[0041] Preparation of the modified tetraethyl orthosilicate sol described in step (3): first, mix ethyl orthosilicate and acetone, stir for 10 minutes, add deionized water, and then ultrasonicate for 10 minutes while stirring, and then vigorously stir Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com