Method for preparing a coating for protecting a stone surface against acid rain

A technology that resists acid rain and stone. It is applied in the device, coating, and pretreatment surface of the surface coating liquid. It can solve the problem that the stone is easy to be corroded and eroded, and achieve outstanding acid and alkali resistance and stain resistance. and the effect of improving acid resistance and reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further illustrate the present invention below by embodiment

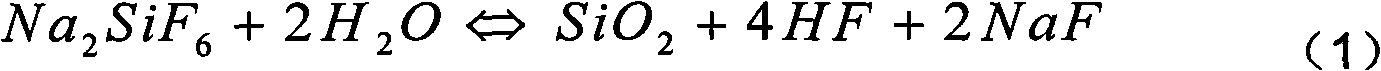

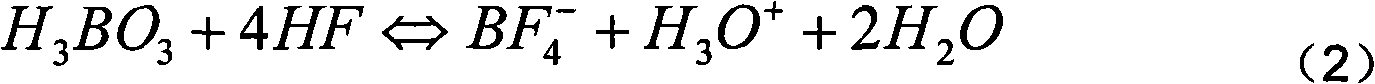

[0024] Preparation of anti-acid rain film layer on stone surface:

[0025] 1. The main materials for making the coating include: stone, Na 2 SiF 6 (analytical pure), anhydrous acetone (chemical pure), hydrochloric acid (analytical pure), H 3 BO 3 (analytical pure), cetyltrimethylammonium chloride (analytical pure), n-butanol, absolute ethanol, ammonia water (chemical pure), polyvinyl chloride film.

[0026] 2. The main equipment involves: ultrasonic cleaning machine, electric stirring, drying box, PH meter.

[0027] 3. The production process of the anti-acid rain environmental coating for stone buildings is as follows:

[0028] (A) Stone cleaning

[0029] The surface of the stone is ultrasonically cleaned first with deionized water and a cleaning agent composed of an organic solvent, and dried in the air. The organic solvent is prepared from acetone and ethanol at a volume ratio of 1:1 to 1:5.

[0030...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com