A waste incineration treatment device

A technology for processing equipment and garbage, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as unsatisfactory, imperfect, and air cannot be supplied normally, and achieve improved incineration treatment quality, high interception effect, and use cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

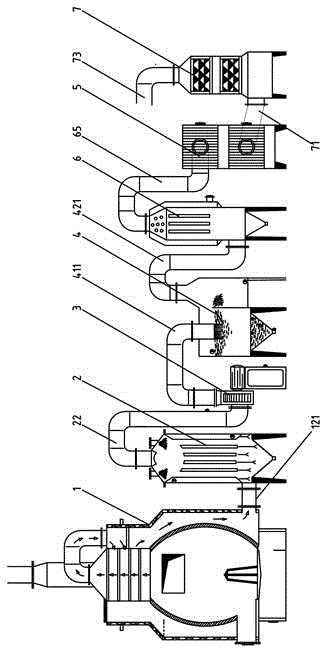

[0031] Such as figure 1 As shown, the present invention includes an incinerator 1, a quenching type high-pressure spray dedusting device 2, an induced draft fan 3, a flue gas melting water exchange treatment device 4, a flue gas treatment condenser 6, a combined sticky dust collector 5, and activated carbon Adsorption chamber 7, these components are connected one by one in the above order;

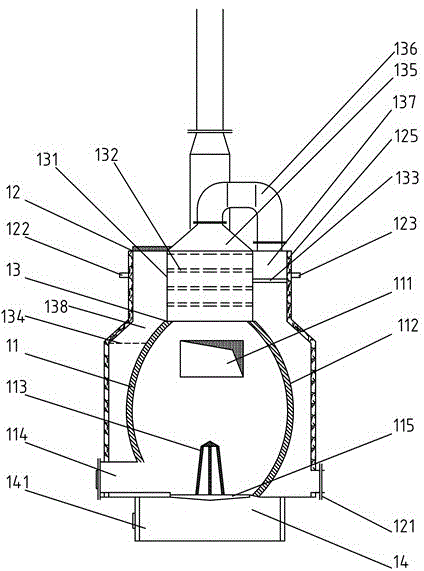

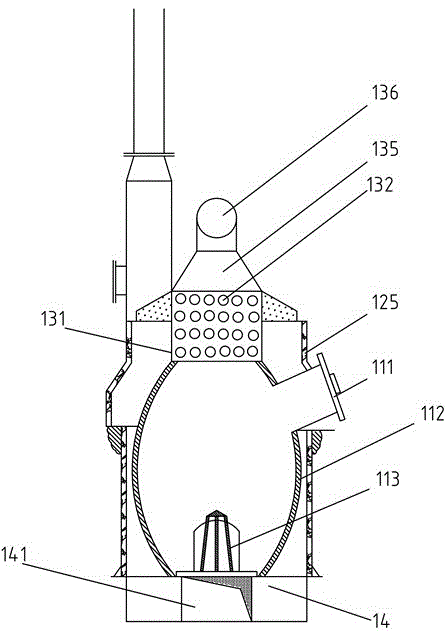

[0032] Such as figure 2 , image 3 As shown, the incinerator 1 includes a body of furnace 12, a furnace combustion chamber 11, a second combustion chamber 13, and a body of furnace base 14. In the middle and upper part, the second combustion chamber 13 is also connected with the upper end of the furnace combustion chamber 11, the furnace body base 14 is arranged on the bottom surface of the furnace body 12, and the furnace body base 14 is also connected with the furnace combustion chamber 11; the furnace combustion chamber 11 comprises a furnace 112, Garbage feed port 111, slag removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com