A high-sensitivity three-axis mems accelerometer and its manufacturing process

A high-sensitivity, accelerometer technology, applied in the field of sensors, can solve the problems of high installation accuracy, increased cost, and decreased detection accuracy, and achieves the effect of reducing overall size, accurate detection, and increasing modal isolation ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing, the present invention is described in further detail:

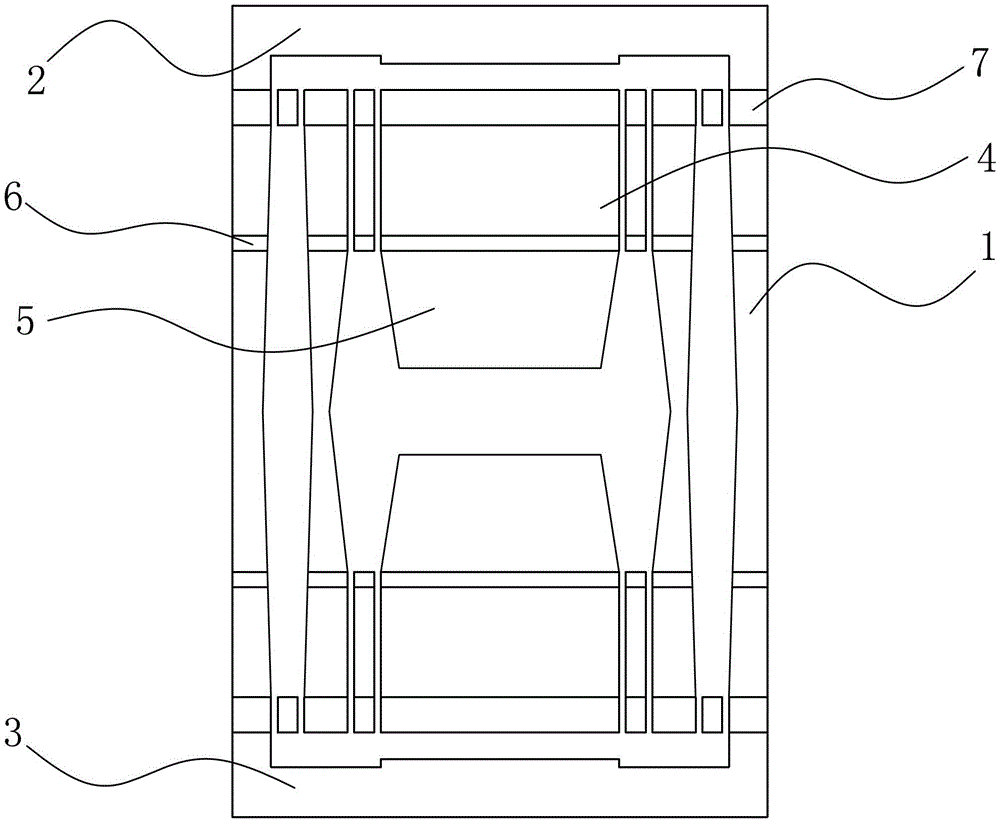

[0055] refer to figure 1 , according to a kind of high-sensitivity three-axis MEMS accelerometer provided by the present invention, comprise: measuring body 1, the upper cover plate silicon chip 2 that is connected with described measuring body 1 and the lower cover plate silicon chip 3; Said measuring body 1 1. The upper cover silicon wafer 2 and the lower cover silicon wafer 3 are respectively provided with electrodes; the measuring body 1 adopts a silicon-on-insulator epitaxial structure including an upper silicon layer 4 and a lower silicon layer 5, referred to as SOI structure. A buried oxide layer 6 is arranged between each silicon layer, and an epitaxial layer 7 is formed on the surface of the upper silicon layer 4 .

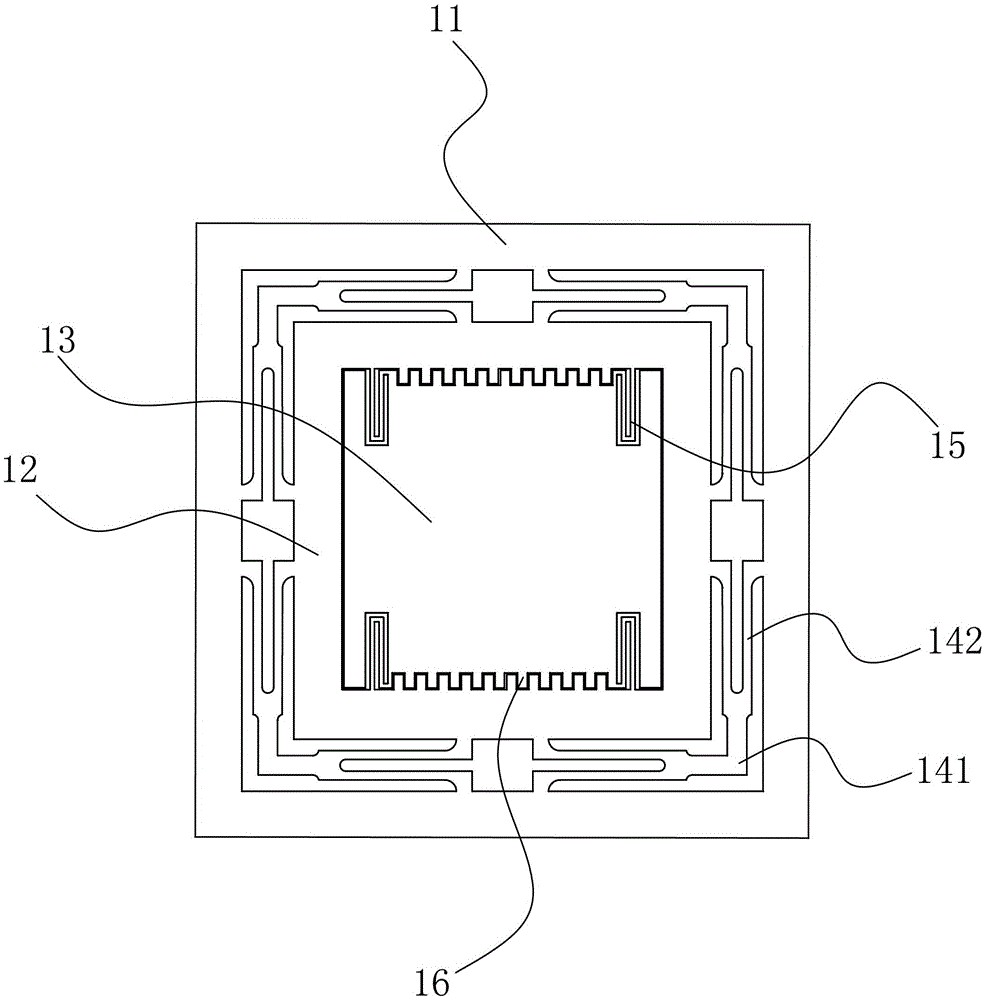

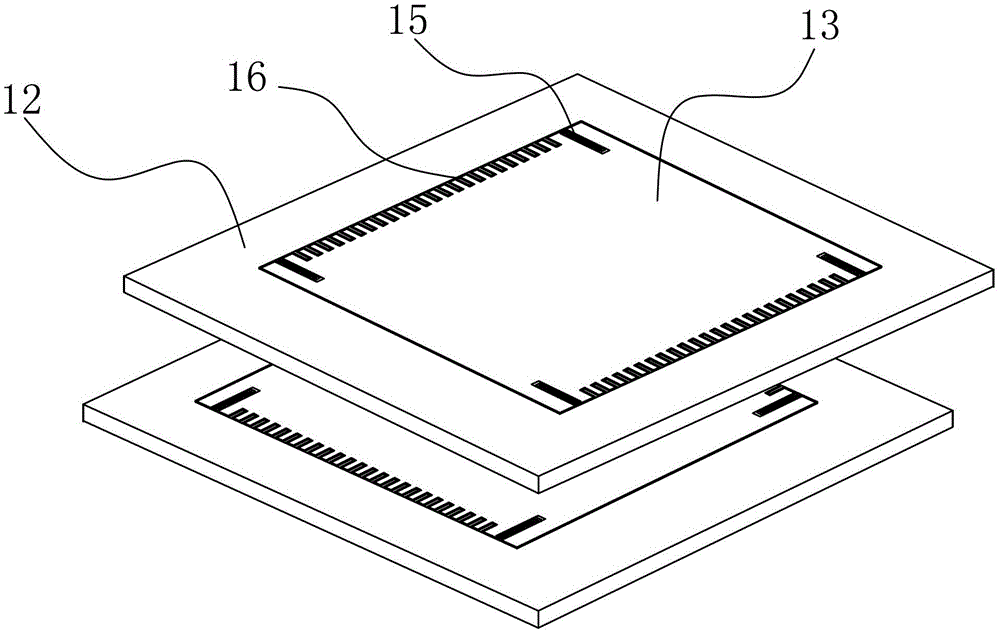

[0056] see figure 2 , the measuring body 1 includes an outer frame 11 , an inner frame 12 inside the outer frame 11 and a mass block 13 ; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com