Thin-film transistor, manufacturing method of thin-film transistor, array substrate and display device

A technology of thin film transistors and substrate substrates, which is applied in transistors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problem of increased subthreshold swing of thin film transistors, affecting the semiconductor characteristics of thin film transistors, reducing nitrogen vacancy mobility, etc. problem, achieve the effect of reducing subthreshold swing, improving semiconductor characteristics, and improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

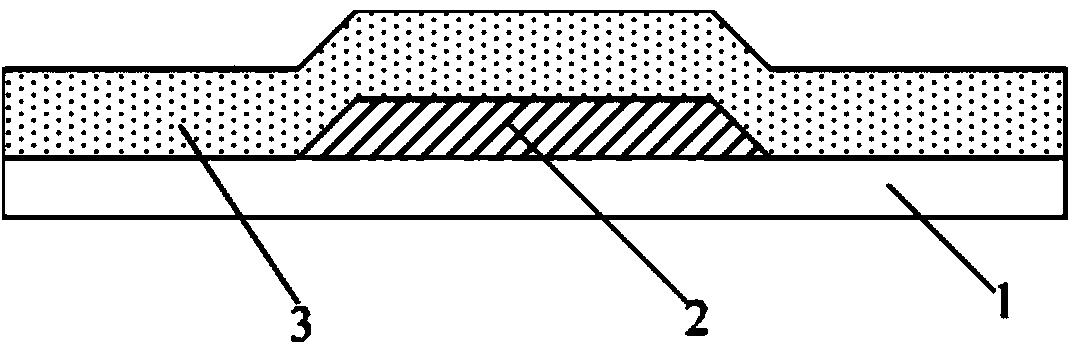

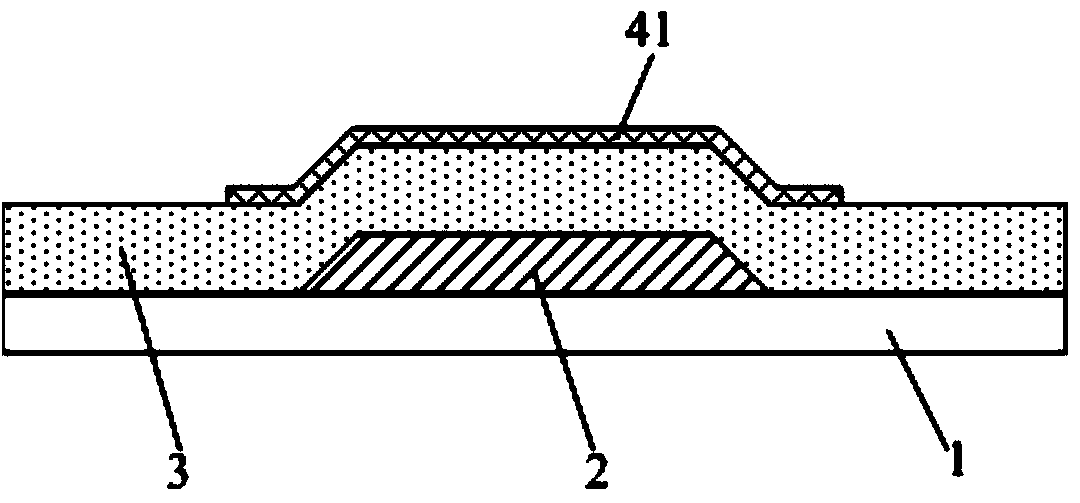

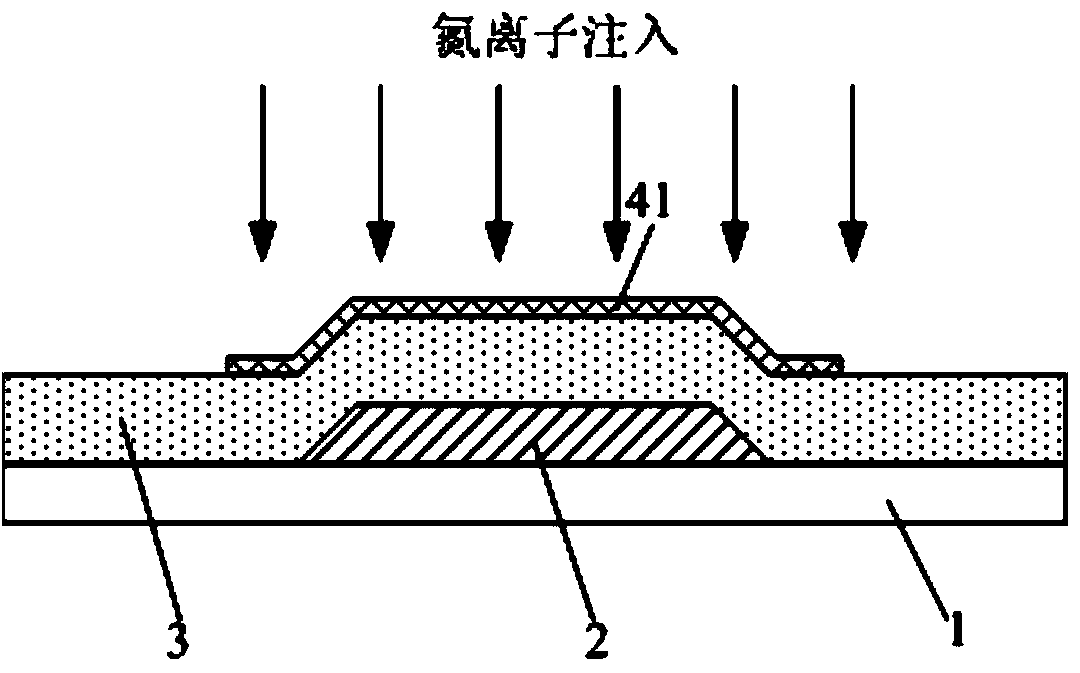

[0032] This embodiment provides a method for preparing a thin film transistor, such as Figure 1-6 As shown, it includes forming a gate 2, a gate insulating layer 3, an active region 4, a source 5 and a drain 6 on a base substrate 1, and the active region 4 is formed by using ZnON material, while forming the active region 4 Nitrogen ion implantation is performed on the active region 4 so that the sub-threshold swing of the thin film transistor is ≤0.5mV / dec.

[0033] Among them, the sub-threshold swing is the slope of the part of the semiconductor output characteristic curve from the off state (off state) to the on state (conducting state). The smaller the slope, the response of the thin film transistor from the off state to the on state The faster the speed, correspondingly, the better the subthreshold swing characteristics, and the better the performance of the thin film transistor; the larger the slope, the slower the response speed of the thin film transistor from the off ...

Embodiment 2

[0046] This embodiment provides a method for manufacturing a thin film transistor. The difference from Embodiment 1 is that the gate is formed above the active region, that is, the thin film transistor in this embodiment has a top-gate structure.

[0047] The preparation method of other structures of the thin film transistor in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

[0048] Beneficial effects of embodiment 1-2: in the preparation method of the thin film transistor provided in embodiment 1-2, nitrogen ion implantation is performed on the active region while forming the active region, so that the active region is in an effective conductive position The concentration of nitrogen ions is greatly increased, so that when the thin film transistor is in the working state, the nitrogen element lost due to the diffusion effect in the active region can be sufficiently replenished, thereby greatly improving the mobility of nitrogen vacancies in...

Embodiment 3

[0050] This embodiment provides a thin film transistor, which is manufactured by any one of the preparation methods in Embodiments 1-2.

[0051] In this embodiment, the active region of the thin film transistor includes a first active region layer and a second active region layer, the second active region layer is located on the first active region layer, and the first active region layer is located The concentration of nitrogen ions at the effective conduction position is greater than the concentration of nitrogen ions at the effective conduction position in the second active region layer. Such setting can make the nitrogen ions in the first active region layer replenish into the second active region layer during the operation of the thin film transistor, and be in an effective conductive position in the second active region layer, thereby improving the The mobility of nitrogen vacancies in the entire active region further increases the mobility of carriers in the active regi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com