Novel power conversion unit allowing laminated coating row and composite busbar to be used in hybrid mode

A composite busbar and conversion unit technology, which is applied in the field of new power conversion units, can solve the problems of multiple main circuit cable connections, easily damaged power devices, and large stray inductance of the circuit, so as to reduce operating losses and maintenance costs, and improve Reliability, effect of reducing stray inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

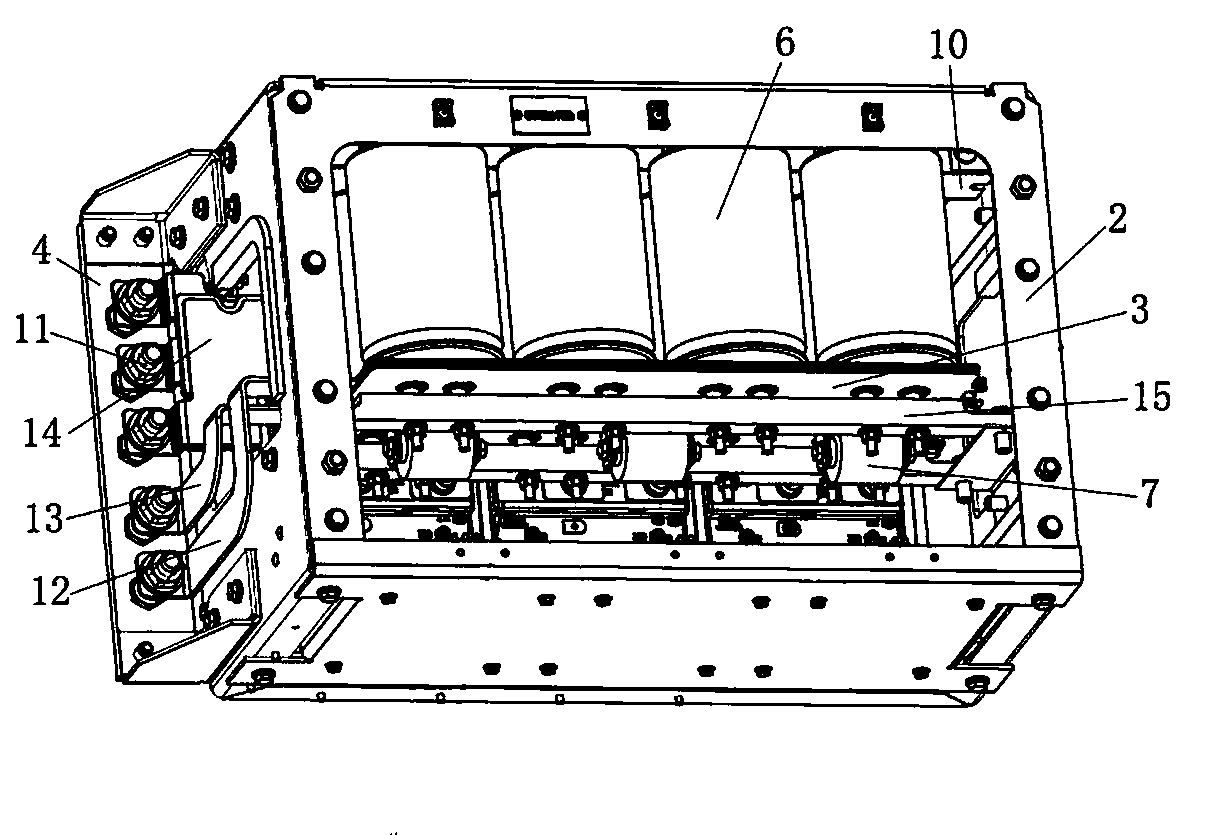

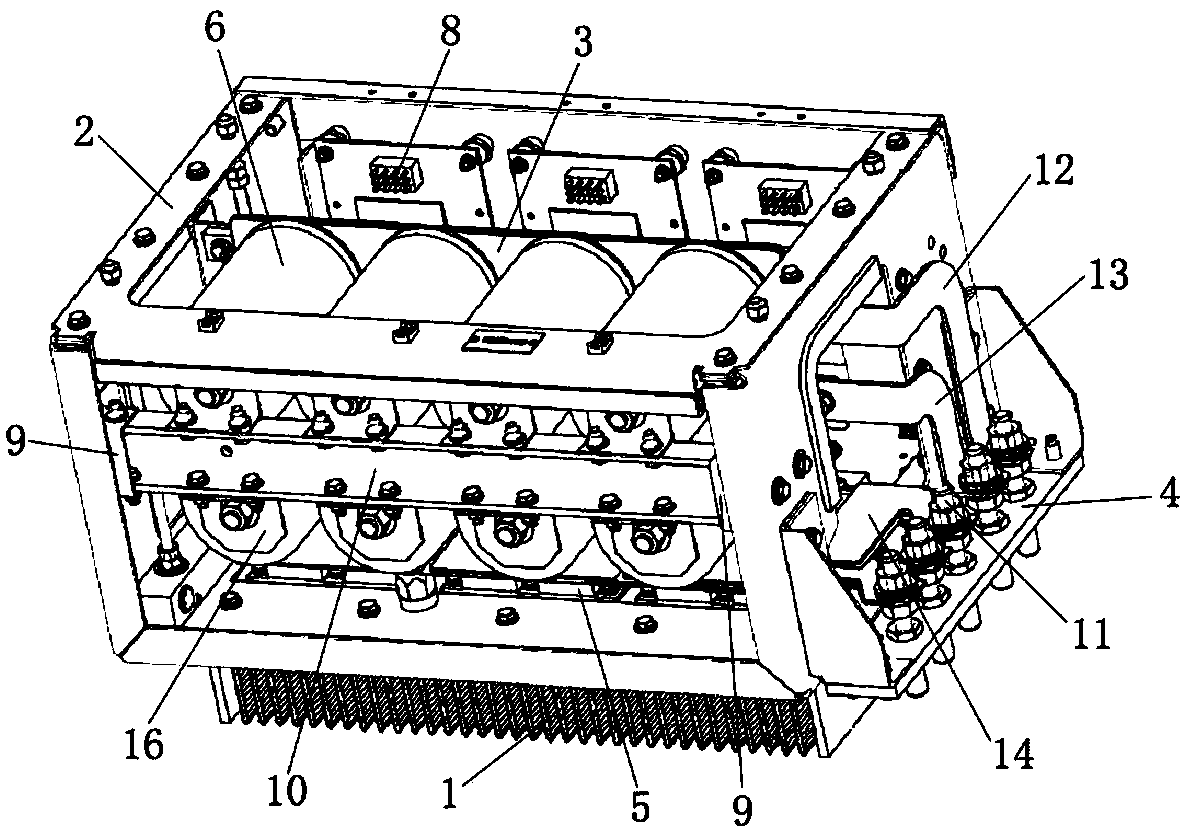

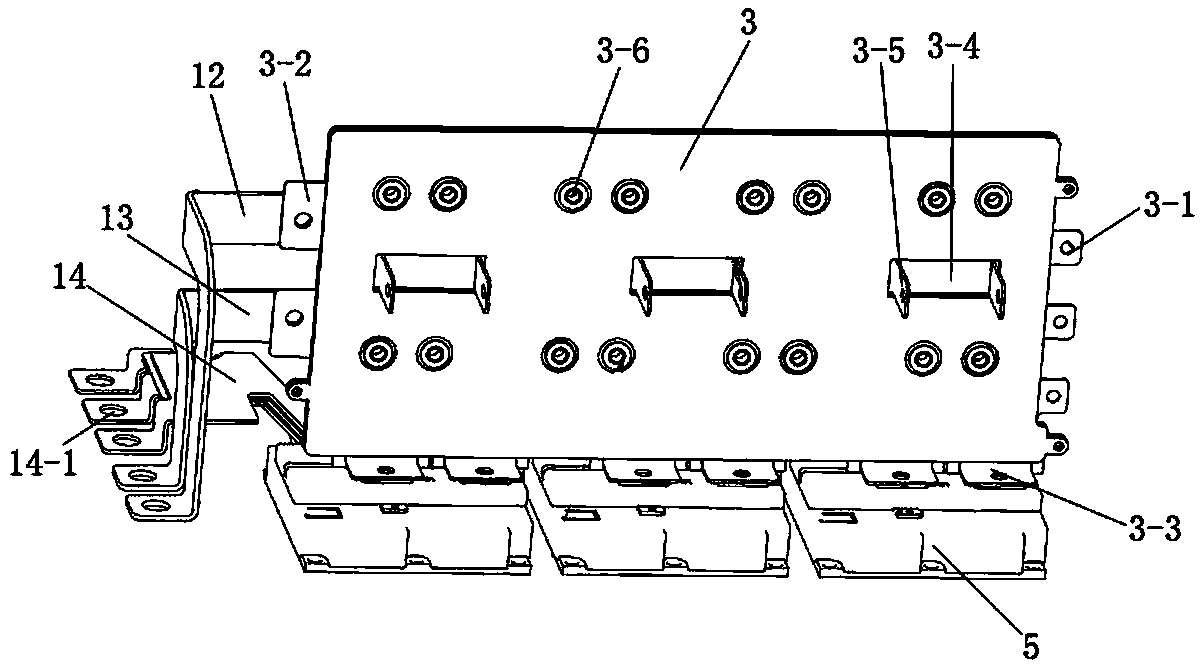

[0034] Such as Figure 1 to Figure 4 As shown, a new type of power conversion unit mixed with laminated spray bars and composite busbars, including air-cooled radiator 1, frame 2, composite busbar 3, mounting plate 4, three IGBTs 5, eight support capacitors 6, Three absorption capacitors 7, three drive circuit boards 8 and two discharge resistors; frame 2 is installed on the top of air-cooled radiator 1, and composite busbar 3 is installed between the left and right frame walls in frame 2; The surface of the base plate of the cold radiator 1 is connected to the composite busbar 3 respectively; eight support capacitors 6 are installed in the frame 2 through the insulating support plate 10 at a position between the rear frame wall and the composite busbar 3, and the eight support capacitors 6 is divided into upper and lower rows, each row has four supporting capacitors 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com