Processing method of sargassum fusiforme oral liquid

A vegetable oral liquid and processing method technology, which is applied in the field of hijiki oral liquid processing, can solve problems such as hidden safety hazards and residual impurities, and achieve the effects of convenient consumption, low bacterial content, and improved nutritional and health care value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The processing method of the hijiki oral liquid comprises the following steps: (1) soaking and washing, placing the hijiki material in clear water to wash away the salinity and sediment on the surface of the material, the weight ratio of the clear water to the hijiki being 1:3-5, Soaking time is 2-3 hours; (2) Cooking, remove and drain the soaked materials and put them in a steamer for cooking, the cooking temperature is 100-120°, and the cooking time is 2-3 hours; (3) Vacuum drying, put them in a closed Heating and drying in the container and vacuuming at the same time, the pressure in the container is kept below 800Pa, the drying time is 40-50min, and the moisture content of the material after completion is below 15%; 40 mesh, separate the bud ear from the stem and remove the bud ear, and keep the stem; (5) pulverize, grind the screened material through a pulverizer, so that the particle size of the material is less than 3mm; (6) acid wash out arsenic, Soak the pulver...

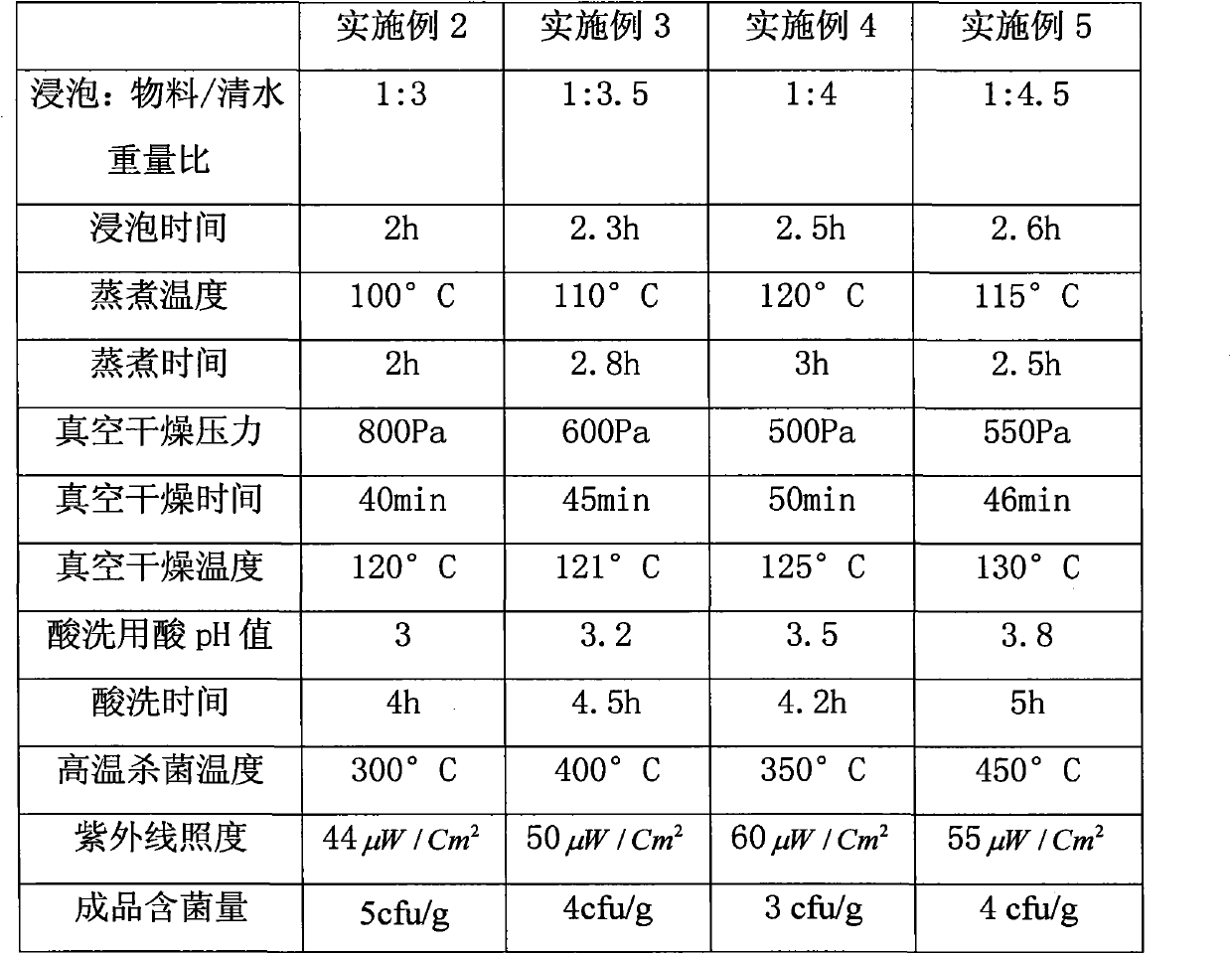

Embodiment 2-5

[0026] See Table 1 for the parameters of each step in Examples 2-5.

[0027]

[0028] Table 1

[0029] As can be seen from Table 1, the hijiki oral liquid prepared by this process is far lower than the 100cfu / g bacterial content allowed by the national standard.

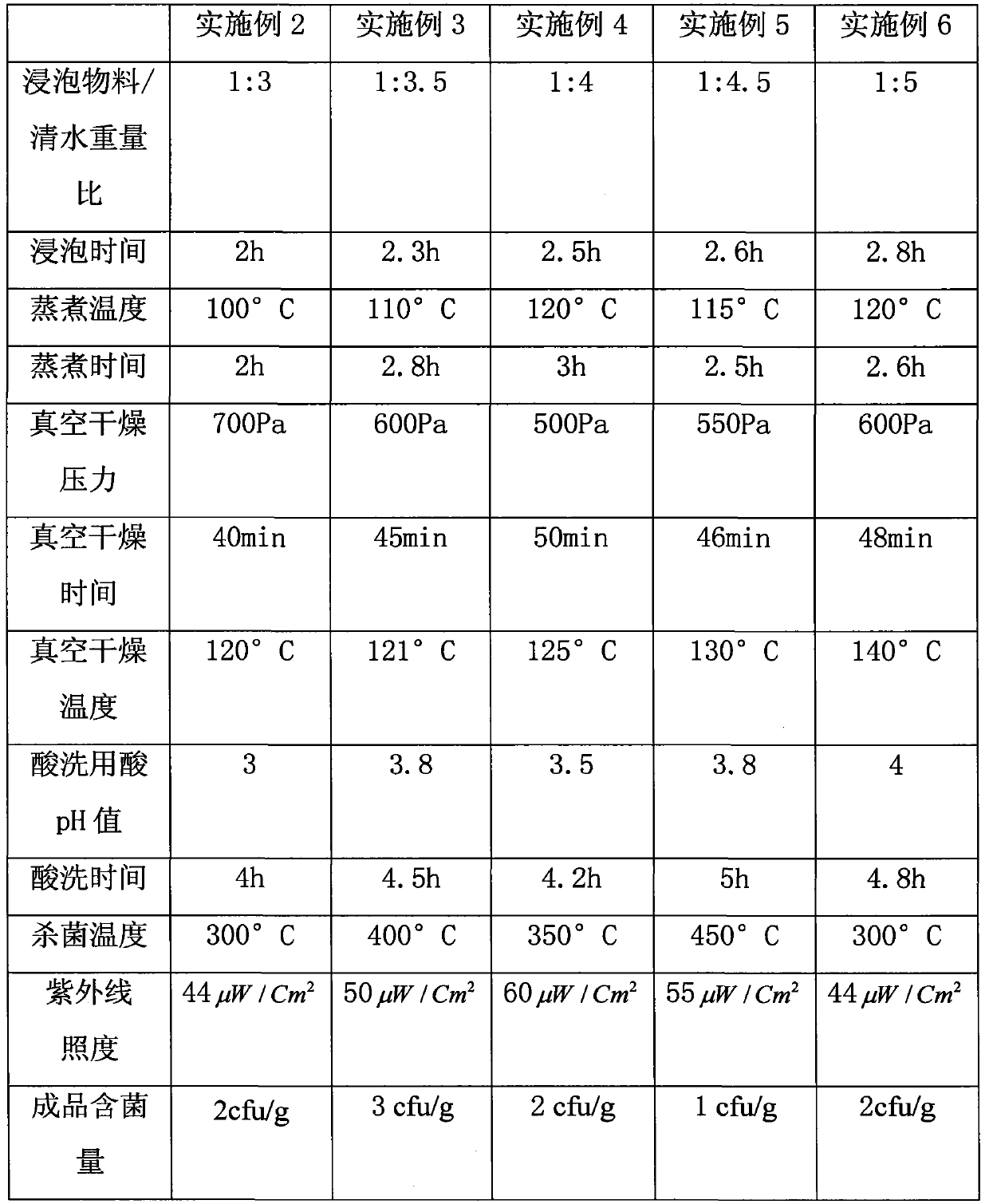

Embodiment 6-10

[0031] See Table 2 for the parameters of each step in Examples 6-10.

[0032]

[0033] Table 2

[0034] The nutritional components of the oral liquid obtained in Examples 6-10 are consistent with the aforementioned research results, and a variety of auxiliary nutritional elements are added, which is suitable for long-term administration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com