Compressed air drying device based on vortex tube refrigeration technology and working method of compressed air drying device

A technology of compressed air and drying equipment, applied in the field of compressed air, which can solve the problems of complex structure of drying equipment, low working efficiency, waste of air potential energy, etc., to improve refrigeration efficiency and energy utilization, facilitate operation, and reduce outlet moisture content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

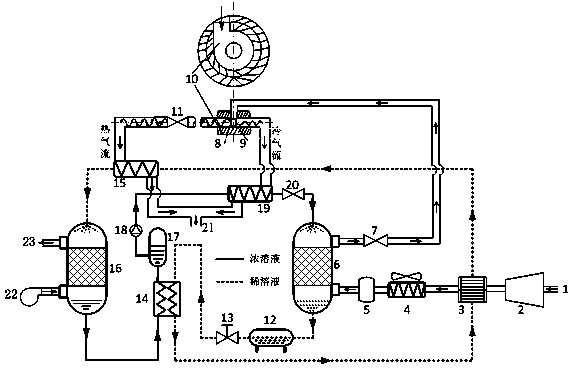

[0019] Embodiment 1 Compressed air drying device based on vortex tube refrigeration technology

[0020] Such as figure 1 As shown, the compressed air drying device based on the vortex tube refrigeration technology includes an air inlet 1, an air compressor 2, a gas-liquid heat exchanger 3, an air cooler 4, a high-pressure gas storage tank 5, a high-pressure dehumidifier 6, and a first control valve 7. Nozzle 8, orifice plate 9, vortex chamber 10, second control valve 11, high pressure liquid storage tank 12, first throttle valve 13, intermediate heat exchanger 14, solution heater 15, normal pressure regenerator 16, normal pressure Pressure storage tank 17, high-pressure solution pump 18, solution cooler 19, third control valve 20, dry air outlet 21, blower fan 22 and regeneration air outlet 23; the above components respectively constitute the compressed air solution deep dehumidification drying assembly, high-pressure solution Dehumidification and atmospheric solution regener...

Embodiment 2

[0025] Embodiment 2 Working method of compressed air drying device based on vortex tube refrigeration technology

[0026] The working method of the compressed air high-efficiency dehumidification and drying device based on the vortex tube refrigeration technology mainly includes a compressed air drying process, a high-pressure solution dehumidification regeneration cycle process, and a vortex tube refrigeration enhanced solution dehumidification regeneration process.

[0027] The compressed air drying process is as follows: the wet air enters the air compressor 2 through the air inlet 1 to obtain compressed air after being compressed, the compressed air is cooled by the gas-liquid heat exchanger 3 and the air cooler 4, and then enters the high-pressure dehumidifier through the high-pressure gas storage tank 5 6. At the same time, the concentrated solution is pressurized and cooled by the high-pressure solution pump 18 and the solution cooler 19 in turn, and then enters the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com