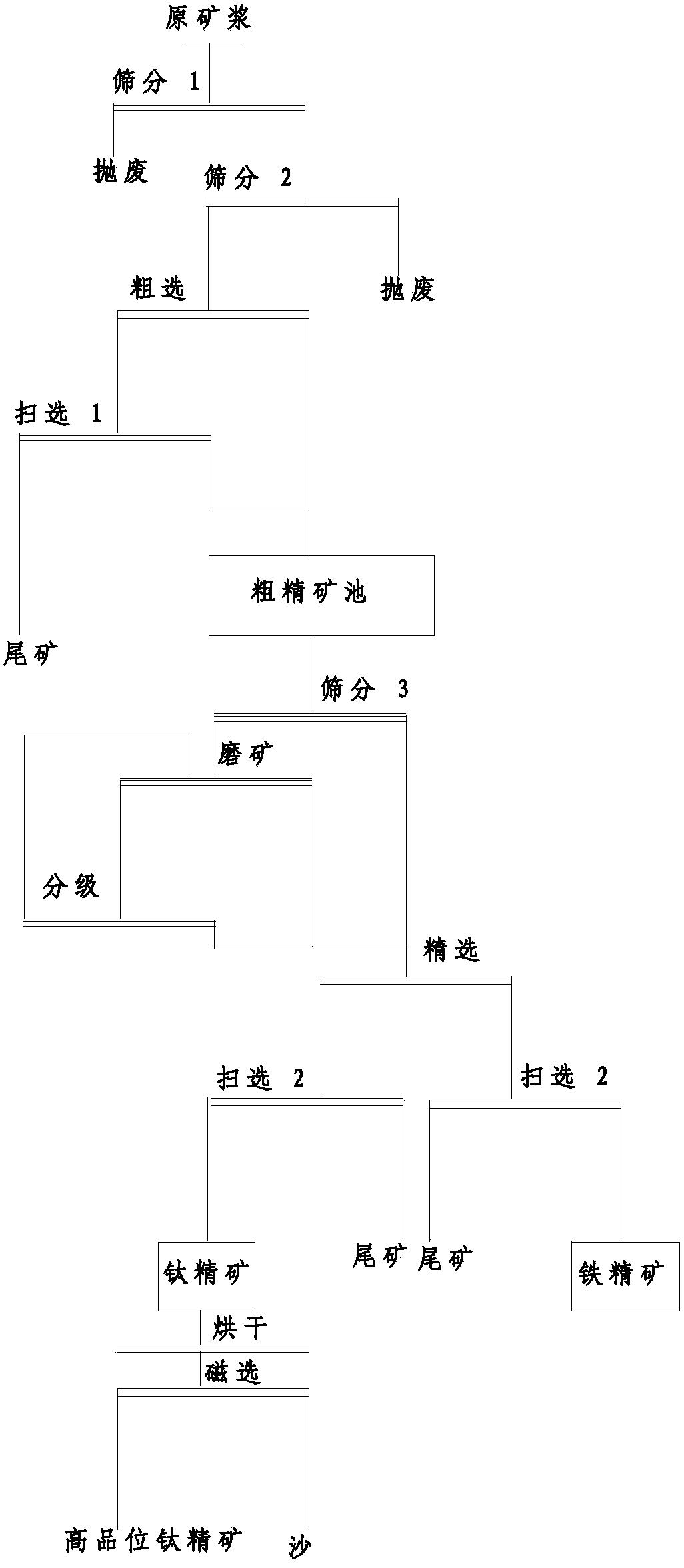

Combined magnetic separation process for selecting weathering sand ilmenite

A technology for ilmenite and molding sand, applied in magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of low economic value, low concentrate grade, small processing capacity, etc., and achieve enhanced processing effect and high production efficiency , the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Weathering type sandy ilmenite beneficiation combined magnetic separation process of the present invention comprises the following steps:

[0026] According to chemical analysis and phase analysis, TiO in weathered placer 2 The grade is generally 3%-15%, TiO 2 It mainly occurs in ilmenite in the form of independent minerals, and a small amount is distributed in titanium magnetite and rutile, and secondly it occurs in limonite and silicate in the form of isomorphism. The raw ore of an ilmenite mine in Guangxi The results of the laboratory analysis are as an example:

[0027] Raw ore multi-element analysis results Table 3

[0028] the element

TiO 2

TF

S

P

As(10 -6 )

SiO 2

MgO

Content (%)

6.74

16.42

0.02

0.13

5.66

28.57

0.87

the element

al 2 o 3

CaO

K 2 o

Na 2 o

/

/

/

Content (%)

24.08

0.45

0.38

0.55

/

/

/

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com