Casting method of high-volume-fraction reinforced-phase titanium-based composite material casting

A titanium-based composite material and high volume fraction technology, applied in the casting field of titanium-based composite materials, can solve the problems of complex centrifugal casting method, difficult filling of gravity casting, difficult to guarantee internal quality, etc. The effect of uniform hardness distribution, dimensional accuracy and high surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

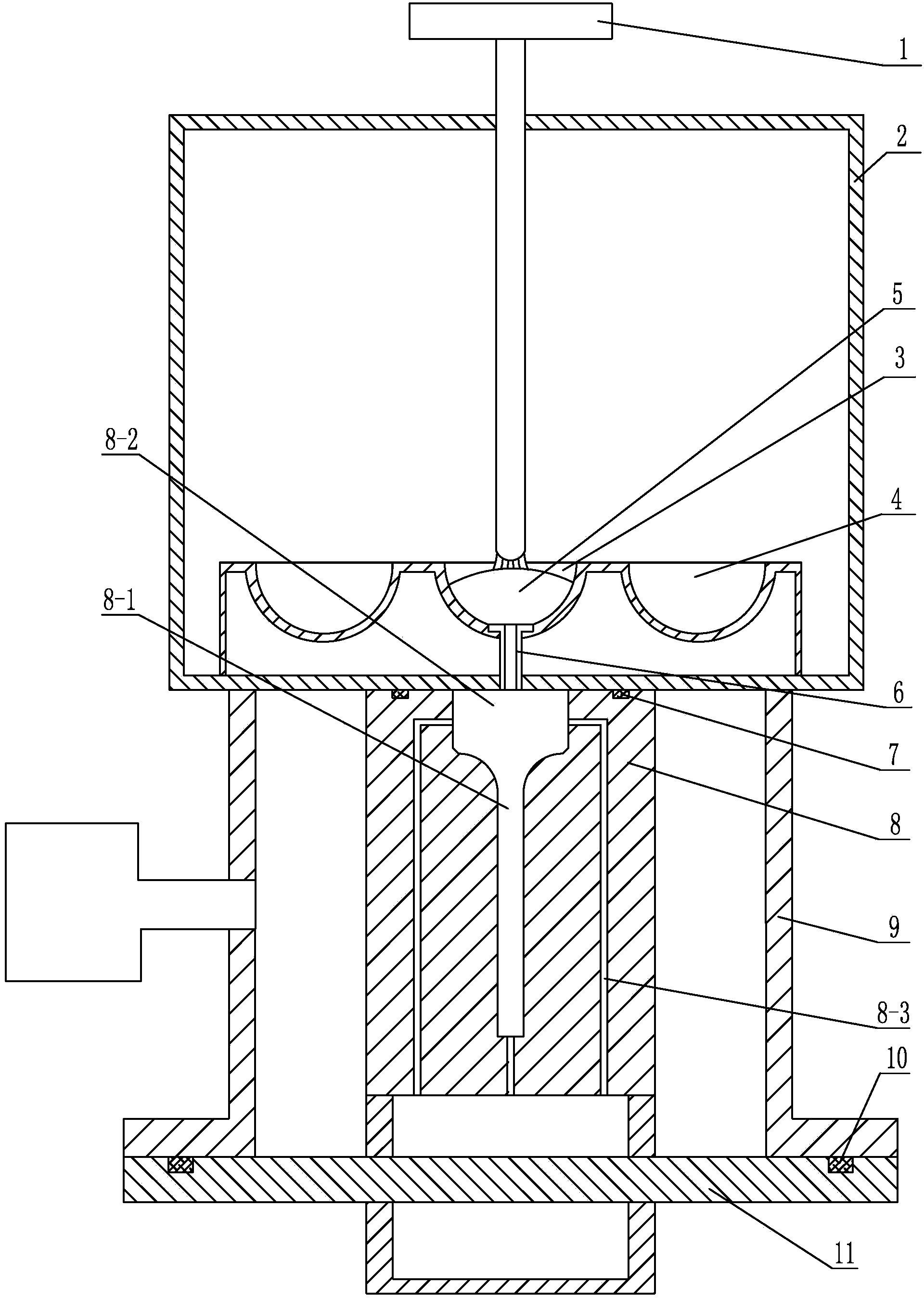

[0020] Specific implementation mode one: combine figure 1 and Figure 7 To illustrate, the casting method of a high volume fraction reinforced phase titanium-based composite casting in this embodiment is carried out in accordance with the following steps:

[0021] Step 1, manufacture the suction casting mold 8, the suction casting mold 8 is a metal mold, the middle part of the suction casting mold 8 is processed with a cavity 8-1, and the inside of the suction casting mold 8 is processed with two exhaust channels 8-3, Two exhaust passages 8-3 are arranged side by side on both sides of the cavity 8-1, the upper end of the exhaust passage 8-3 communicates with the cavity 8-1, and the lower end of the exhaust passage 8-3 communicates with the suction casting mold 8. The bottom is offset, the upper surface of the suction casting mold 8 is provided with an annular sealing groove, and the gate 8-2 of the suction casting mold 8 is located in the annular sealing groove;

[0022] Ste...

specific Embodiment approach 2

[0033] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the titanium alloy matrix material of the high volume fraction reinforced titanium-based composite material in step 2 is TAl titanium alloy, TC 4 Titanium alloy, TB 5 Titanium alloy or Ti 60 titanium alloy. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034]Embodiment 3: This embodiment differs from Embodiment 1 to Embodiment 2 in that: in step 6, the melting current is 400A. After smelting for 2.5 minutes, increase the arc current to 625A and keep it for 1.5 minutes to obtain a superheated melt. The other steps and parameters are the same as those in the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com