Preparation method of superfine silver powder for electronic material

An electronic material and ultra-fine silver technology, which is applied in the field of preparation of ultra-fine silver powder for electronic materials, can solve the problems of low cost, unsatisfactory properties such as the purity and particle size of the ultra-fine silver powder, and the comprehensive performance of the ultra-fine silver powder is not good enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

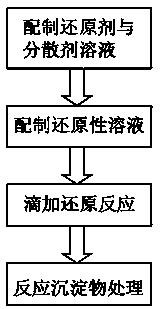

Image

Examples

Embodiment 1

[0018] The specific preparation method is as follows:

[0019] a) Prepare reducing agent and dispersant solution. The specific preparation process is: first take a certain amount of ascorbic acid, dissolve it in deionized water, and make a reducing agent solution with a concentration of 0.4mol / L; then take an appropriate amount of oleic acid, whose mass is ascorbic acid 3%, dissolved in absolute ethanol to make a dispersant solution with a concentration of 3g / L.

[0020] b) Prepare the reducing solution. The specific preparation process is as follows: first pour the reducing agent solution into a special container equipped with a stirring device, and heat it to 50°C in a water bath; then adjust the stirring speed to 400r / min, and put the prepared Add the dispersant solution into the reducing agent solution, and stir for 10 minutes at a speed of 400r / min, so that the reducing agent is evenly dispersed, and the reducing solution is prepared.

[0021] c) Dropping reduction react...

Embodiment 2

[0024] The specific preparation method is as follows:

[0025] a) Prepare reducing agent and dispersant solution, the specific preparation process is: first take a certain amount of ascorbic acid, dissolve it in deionized water, and make a reducing agent solution with a concentration of 0.6mol / L; then take an appropriate amount of oleic acid, whose mass is ascorbic acid 3%, dissolved in absolute ethanol to make a dispersant solution with a concentration of 5g / L.

[0026] b) Prepare the reducing solution, the specific preparation process is: first pour the reducing agent solution into a special container equipped with a stirring device, and heat it to 60°C in a water bath; then adjust the stirring speed to 400r / min, and put the prepared Add the dispersant solution into the reducing agent solution, and stir for 10 minutes at a speed of 400r / min, so that the reducing agent is evenly dispersed, and the reducing solution is prepared.

[0027] c) Dropping reduction reaction, the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com