Method for preparing surface micro-nano pattern by two-step method

A micro-nano and graphic technology, applied in welding equipment, manufacturing tools, laser welding equipment, etc., can solve the problems of difficult to realize complex pattern preparation, difficult placement of micro-fiber, etc., to achieve strong controllability and improved resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

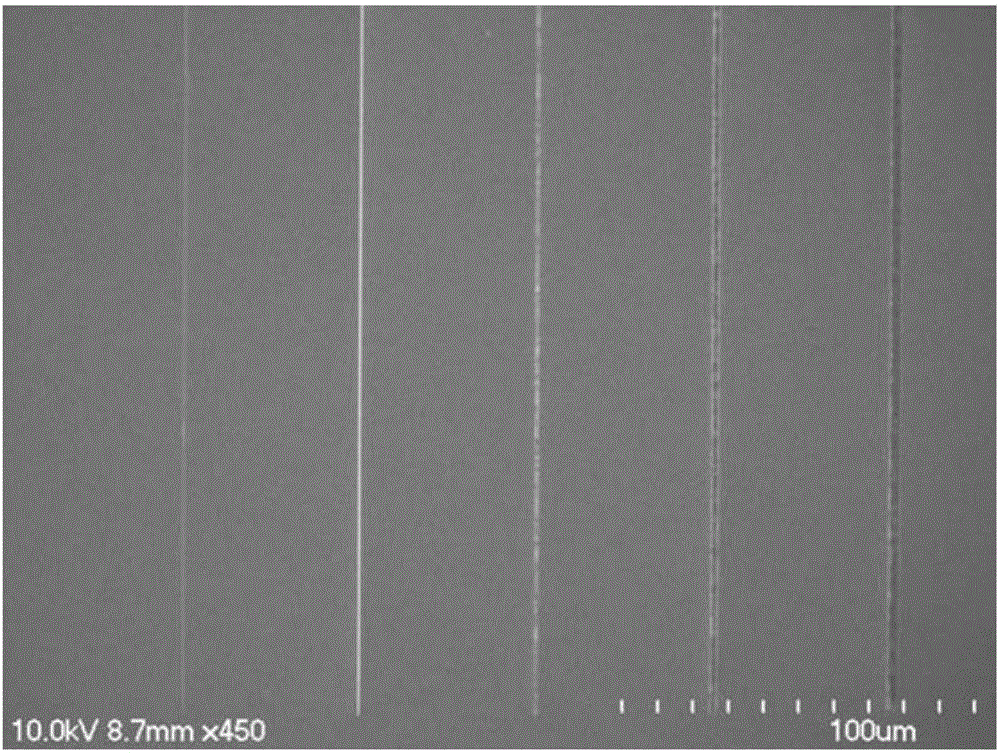

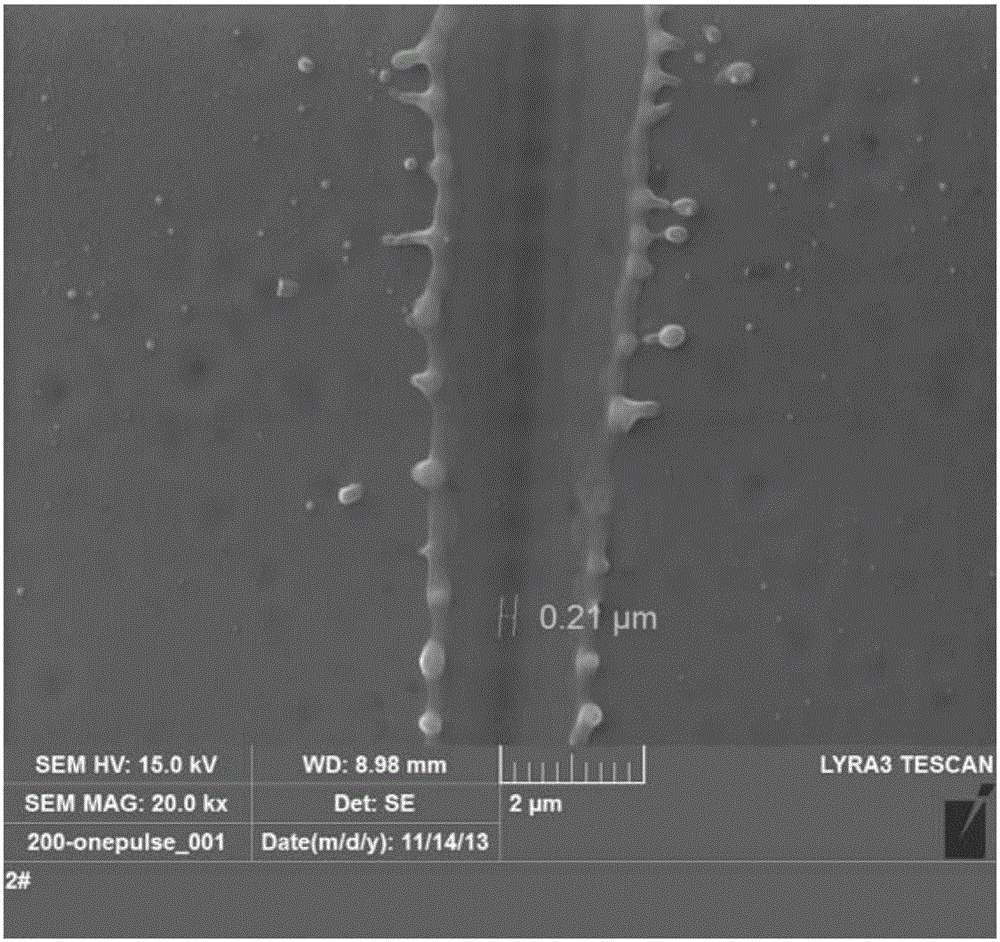

[0040] Example 1. Preparation of micro-nano patterns on the surface of polysilicon using femtosecond laser

[0041] 1. Using the femtosecond laser multiphoton polymerization processing method, the focusing element is prepared on the surface of polysilicon according to the required pattern requirements

[0042](1) Select polysilicon as the material to be processed, and uniformly coat IP-L photoresist (purchased from Nanoscribe, Germany) in the central area of its surface. The characteristic absorption band of IP-L photoresist is 180nm-320nm.

[0043] (2) According to requirements, strip trenches of different widths are to be prepared on the surface of polysilicon. Through calculation (the specific calculation method is as follows: use the finite difference time domain algorithm (FDTD) to calculate the energy field distribution of cylindrical polymeric components with different widths and diameters under the action of the laser, and compare it with the material damage threshol...

Embodiment 2

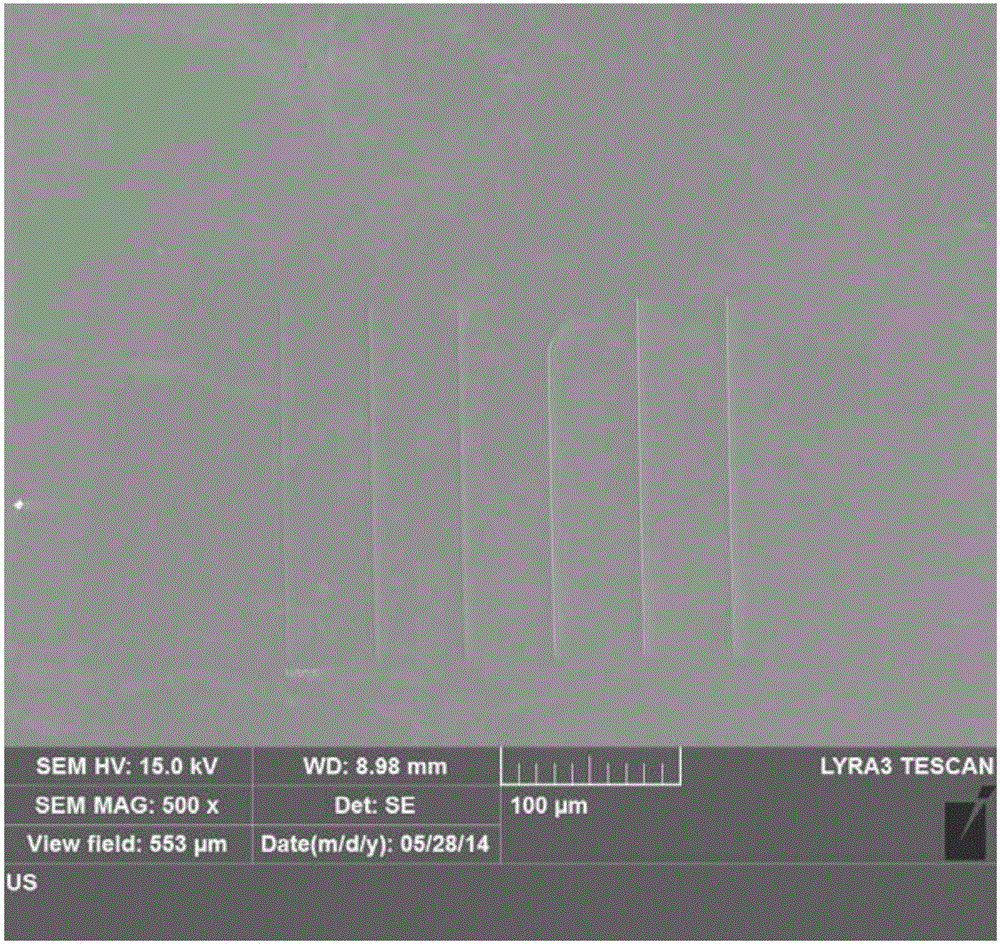

[0054] Example 2. Using nanosecond laser to prepare micro-nano patterns on the surface of polysilicon

[0055] 1. Using the femtosecond laser multiphoton polymerization processing method, the focusing element is prepared on the surface of polysilicon according to the required pattern requirements

[0056] (1) Select polysilicon as the material to be processed, and uniformly coat IP-L photoresist (purchased from Nanoscribe, Germany) in the central area of its surface. The characteristic absorption band of IP-L photoresist is 180nm-320nm.

[0057] (2) According to requirements, strip trenches of different widths are to be prepared on the surface of polysilicon. Through calculation (the specific calculation method is as follows: use the finite difference time domain algorithm (FDTD) to calculate the energy field distribution of cylindrical polymeric components with different widths and diameters under the action of the laser, and compare it with the material damage threshold to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com