Plasma lenses, air bearings, flying heads, nanofabrication systems and applications

An air bearing and plasma technology, applied in the field of nano-processing, can solve the problems of complex processing equipment, low processing efficiency, and cost a lot of money, and achieve the effects of high processing resolution, high processing efficiency, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

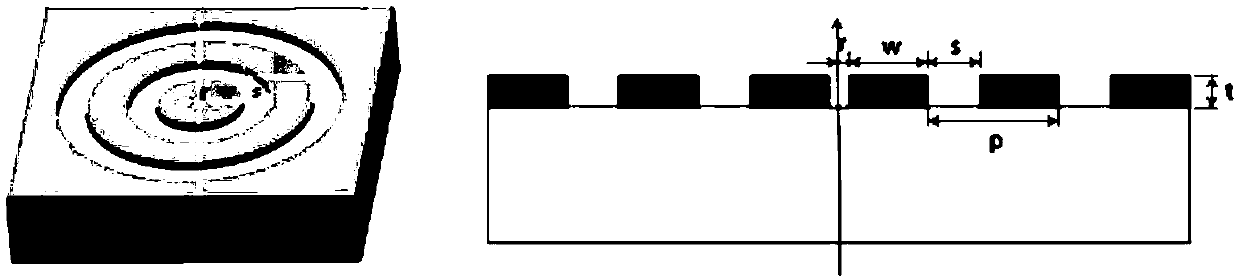

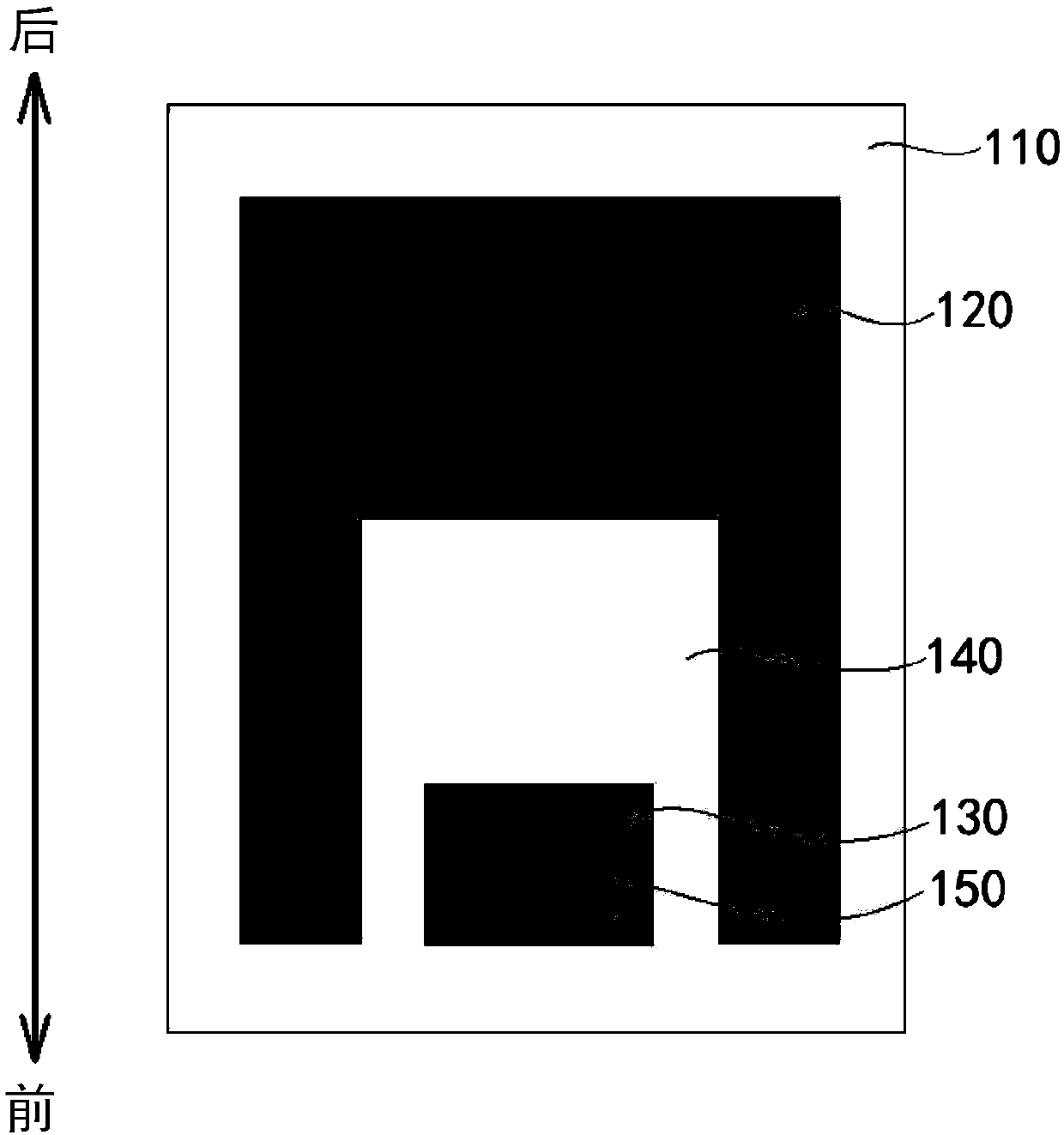

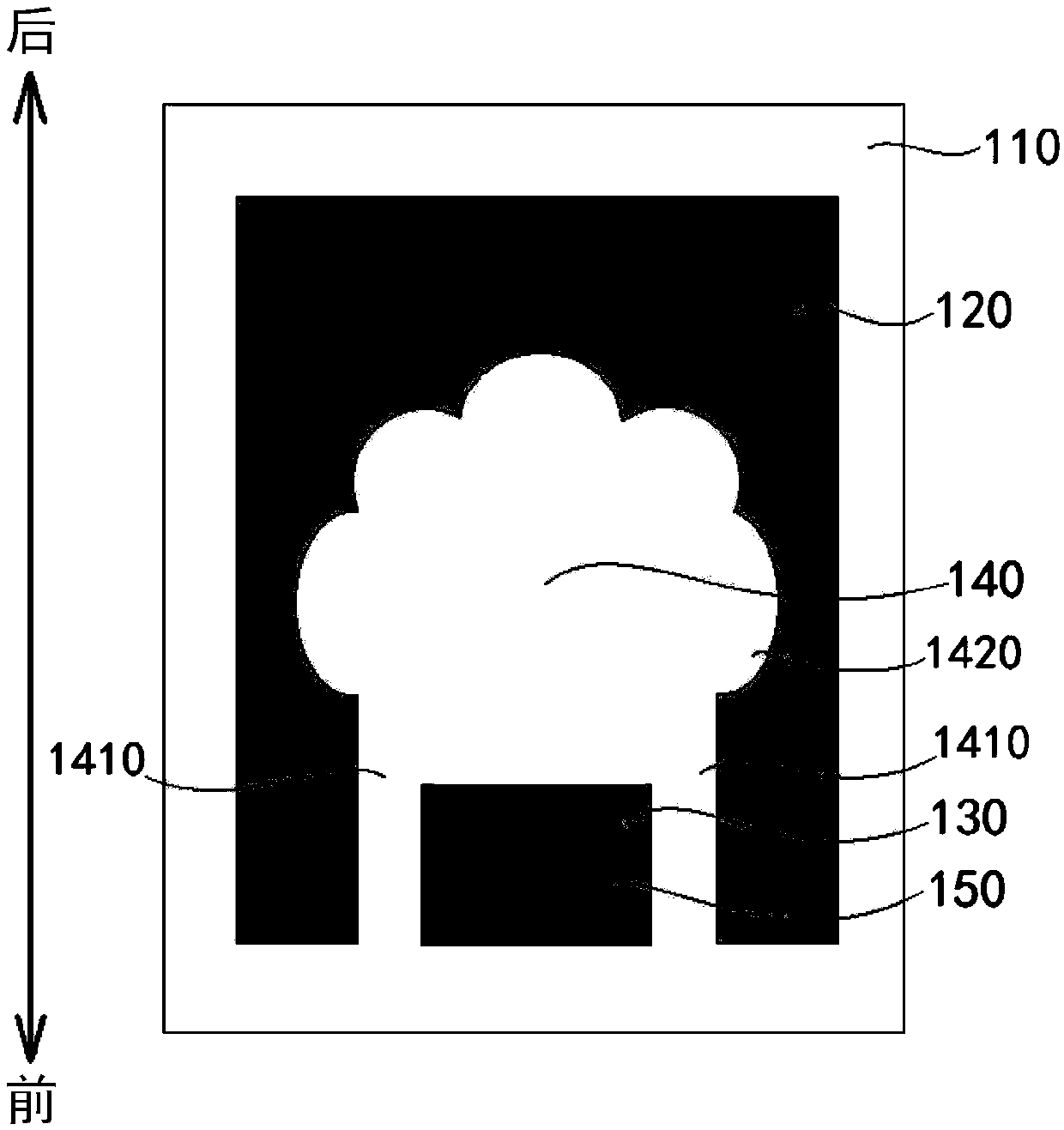

[0092] In this example, in the inorganic thermosensitive photoresist TeO 1.14 The surface is processed by photolithography with the help of nanofabrication system. Specifically, in this embodiment, the structure of the air bearing is as Figure 4 As shown; the plasma lens contains 9 circular grooves, and the material of the metal thin film on the surface of the plasma lens is Cr and the thickness is 30nm, the diameter of the central small hole is 5nm, the groove period of the circular groove is 300nm, and the groove width is 100nm ; The substrate of the flight head is quartz; the beam spot is 30nm.

[0093] The specific operation steps are as follows: adjust the spindle speed to 10000rmp, and wait for the plasma flight head to be in TeO 1.14 When the surface of the photoresist is flying stably, the plasma flying head is moved to the flying height of the disk by the voice coil motor, and the linear velocity at this time is 11.3m / s; then the linearly polarized light with a wav...

Embodiment 2

[0098] In this embodiment, according to the substantially same processing method as in embodiment 1, the inorganic heat-sensitive photoresist TeO with a thickness of 40nm 1.14 The surface is processed by photolithography with the help of nanofabrication system. The difference is that, in this embodiment, the inorganic heat-sensitive photoresist TeO on the substrate surface 1.14 The ratio of argon to oxygen during sputtering preparation is adjusted so that the photoresist TeO 1.14 The sensitivity of the plasma lens is reduced; the thickness of the metal film of the plasma lens is 40nm, the diameter of the central hole is 10nm, the groove period of the circular groove is 350nm, and the groove width is 150nm; the beam spot is 15.8nm; and the spindle speed is 5400rmp.

[0099] The photoresist sample after the photolithographic processing of this embodiment, the result observed under the scanning electron microscope is as follows: Figure 12 shown.

[0100] Figure 12 .a is the...

Embodiment 3

[0102] In this embodiment, according to basically the same processing method as in Embodiment 1, photolithographic processing is performed on the surface of the chemically amplified molecular glass glue FPT-8Boc of the organic photoresist by means of a nanofabrication system. The difference is that in this embodiment, the thickness of the metal thin film of the plasma lens is 100nm, the diameter of the central hole is 20nm, the groove period of the circular groove is 400nm, and the groove width is 200nm; the beam spot is 25nm, and the spindle speed is 1000rmp and, the processed disc is baked in a 100°C oven for 60s to prevent excessive diffusion of the acid generator, and then the disc is taken out of the oven and left at room temperature, and then placed in a developer solution of tetramethylammonium hydroxide For 60 seconds, use a glass rod to stir the developer to make it fully reflect with the exposure area, take out the disk and rinse it with deionized water to remove the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com