Method manufacturing medium density fiberboard by recycling rim charge

A technology of recycling edge material and medium density, which is applied in the field of recycling medium density fiberboard edge material regenerated fiber to manufacture medium density fiberboard. The effect of manufacturing cost and improving comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

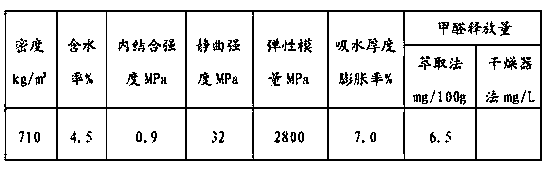

Examples

Embodiment Construction

[0019] The present invention is described in further detail below with embodiment:

[0020] Recycling edge materials to manufacture medium density fiberboard, the production steps are as follows:

[0021] ⑴ Board edge crushing: Send the board edge cut in the original production to the crusher for crushing. The diameter of the crushed dust particles is 0.063mm ~ 1.000mm, and then the dust is transported to the dust bin for storage by a fan;

[0022] ⑵Put the treated wood chips into the thermal grinder to grind out the fibers and send them into the drying pipeline. During the process, 23% of adhesive, 0.5% of paraffin, and 1.5% of curing agent are applied;

[0023] (3) Drying: Spray the dust stored in the dust bin into the drying pipe with a high-pressure fan and mix it evenly with the fiber. During the mixing process, add 5% of the adhesive on the basis of the original adhesive, that is, apply 1.15% of the adhesive agent; the content of dust after mixing is 4.0-5.0%; the inlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com