Composite sound insulation high-resilience automobile main carpet anti-vibration pad and manufacturing method thereof

A shock-proof pad, high-rebound technology, applied in chemical instruments and methods, vehicle parts, special positions of vehicles, etc., can solve the problems of poor shock absorption, poor elastic recovery, and lack of good touch, and achieve flame retardant. Enhanced resistance and slip resistance, good sound absorption, good attraction and elastic recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

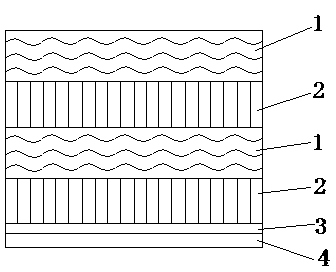

[0062] A composite sound-insulating high-resilience car main carpet anti-shock pad, comprising two layers of horizontally laid sound-absorbing layer 1 and two layers of vertically laid high-elastic layer 2, the sound-absorbing layer 1 and high-elastic layer 2 are interlaced and composited into one, The square gram weight of the sound-absorbing layer 1 is 400g / ㎡, the square gram weight of the high elastic layer 2 is 1100g / ㎡, the sound-absorbing layer 1 adopts ultrafine hollow fibers, and the sound-absorbing layer 1 includes 80% superfine hollow fibers and 20% L-PET fibers; the high elastic layer 2 adopts three-dimensional crimped fibers, and by mass percentage, the high elastic layer 2 includes 70% thick Danny three-dimensional crimped PET fibers and 30% L-PET fibers - PET fiber, an antistatic layer 3 is provided under the high elastic layer 2 of the outer layer, an anti-slip layer 4 is provided under the anti-static layer 3, and an anti-slip pattern is provided on the anti-slip...

Embodiment 2

[0093]A composite sound-insulating high-resilience car main carpet anti-shock pad, comprising two layers of horizontally laid sound-absorbing layer 1 and two layers of vertically laid high-elastic layer 2, the sound-absorbing layer 1 and high-elastic layer 2 are interlaced and composited into one, The square gram weight of the sound-absorbing layer 1 is 500g / ㎡, the square gram weight of the high elastic layer 2 is 1200g / ㎡, the sound-absorbing layer 1 adopts ultrafine hollow fibers, and the sound-absorbing layer 1 includes 85% superfine hollow fibers and 15% L-PET fibers; the high elastic layer 2 adopts three-dimensional crimped fibers, and by mass percentage, the high elastic layer 2 includes 75% thick Denier three-dimensional crimped PET fibers and 25% L-PET fibers - PET fiber, an antistatic layer 3 is provided under the high elastic layer 2 of the outer layer, an anti-slip layer 4 is provided under the anti-static layer 3, and an anti-slip pattern is provided on the anti-slip...

Embodiment 3

[0124] A composite sound-insulating high-resilience car main carpet anti-shock pad, comprising two layers of horizontally laid sound-absorbing layer 1 and two layers of vertically laid high-elastic layer 2, the sound-absorbing layer 1 and high-elastic layer 2 are interlaced and composited into one, The square gram weight of the sound-absorbing layer 1 is 600g / ㎡, the square gram weight of the high elastic layer 2 is 1300g / ㎡, the sound-absorbing layer 1 adopts ultrafine hollow fibers, and the sound-absorbing layer 1 includes 90% superfine hollow fibers and 10% L-PET fibers; the high elastic layer 2 adopts three-dimensional crimped fibers, and by mass percentage, the high elastic layer 2 includes 80% thick Denier three-dimensional crimped PET fibers and 20% L-PET fibers - PET fiber, an antistatic layer 3 is provided under the high elastic layer 2 of the outer layer, an anti-slip layer 4 is provided under the anti-static layer 3, and an anti-slip pattern is provided on the anti-sli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square gram weight | aaaaa | aaaaa |

| Square gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com