Tower type air stripping defluorination method for phosphoric acid

A phosphoric acid and defluorination technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of insufficient contact between phosphoric acid and air, difficult continuous production of grooved defluorination process, high wind pressure, etc.

Active Publication Date: 2014-12-03

SINOPEC NANJING ENG & CONSTR +1

View PDF4 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] However, the tank-type defluorination process needs to blow high-temperature air into the phosphoric acid tank, and the air pipe is inserted below the phosphoric acid liquid level. The hot air contacts with the phosphoric acid to increase the temperature of the phosphoric acid and achieve the purpose of defluorination. Generally, multiple deoxidation tanks are required to carry out the process. , such as four 8-meter-high defluorination tanks with a height of 6 meters, the investment of this method is relatively high

In addition, since the continuous phase is phosphoric acid and the dispersed phase is air, part of the phosphoric acid in the defluorination tank is not in sufficient contact with the air, which affects the defluorination effect; the heating method is to blow hot air into the tank, and the air needs to be heated with steam; The method needs to blow hot air to 1-1.5 meters below the liquid level in the phosphoric acid tank, the fan needs high wind pressure (15000Pa), high power consumption, and the tank-type defluorination process is difficult for continuous production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

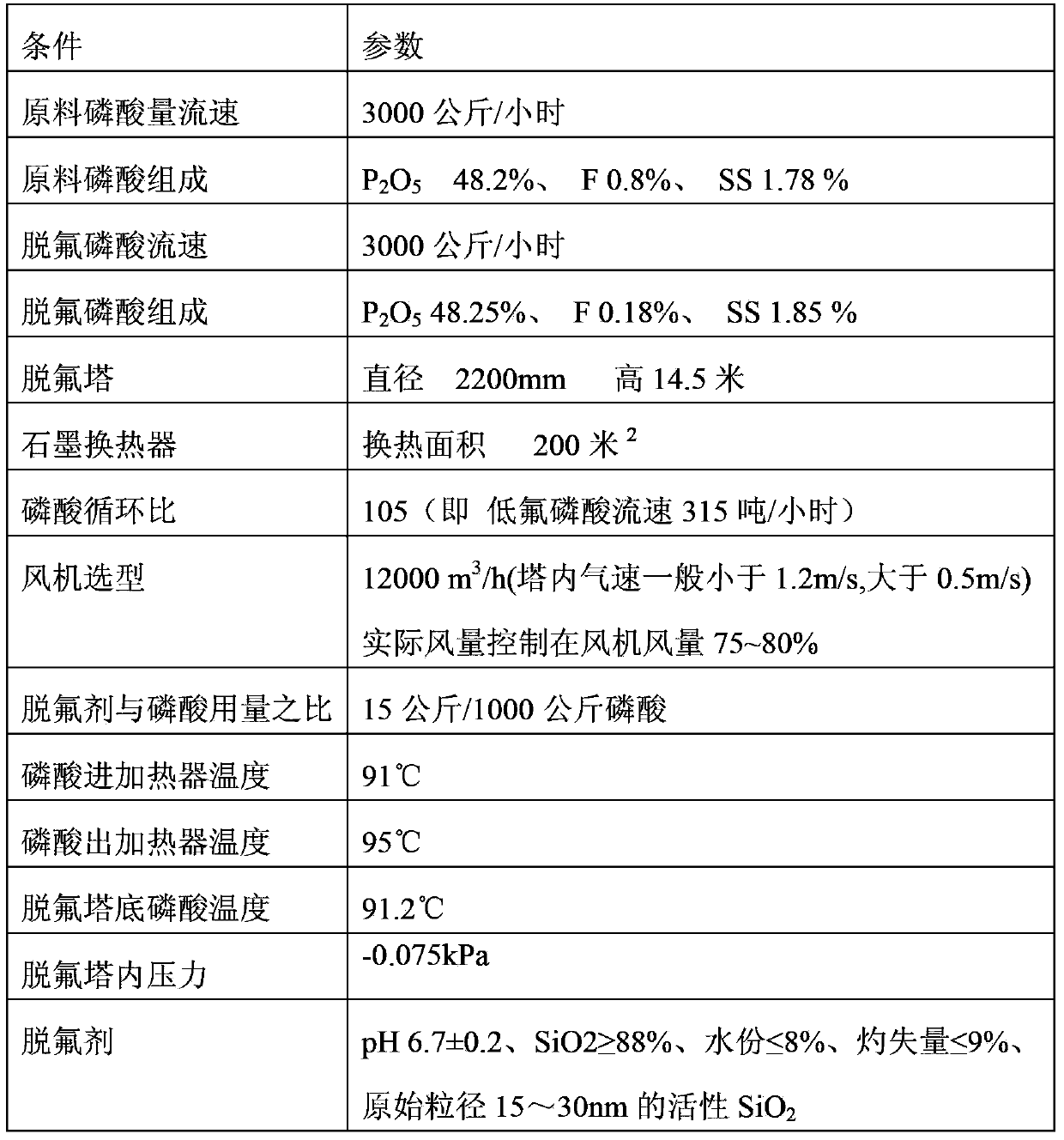

Embodiment 1

[0035] 20,000 tons / year phosphoric acid defluorination plant, the structure and operation process of the plant are as above, and the operating conditions are as follows:

[0036]

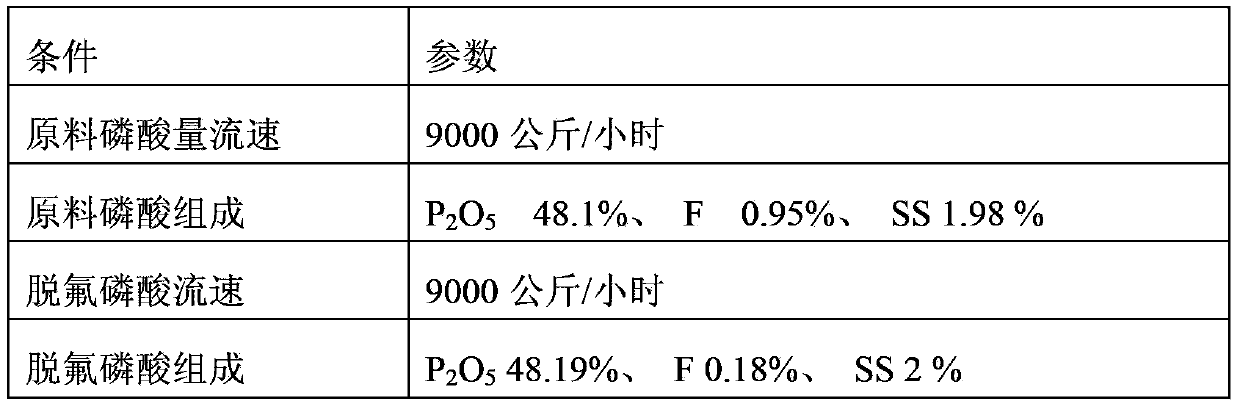

Embodiment 2

[0038] 60,000 tons / year phosphoric acid defluorination plant, the structure and operation process of the plant are as above, and the operating conditions are as follows:

[0039]

[0040]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

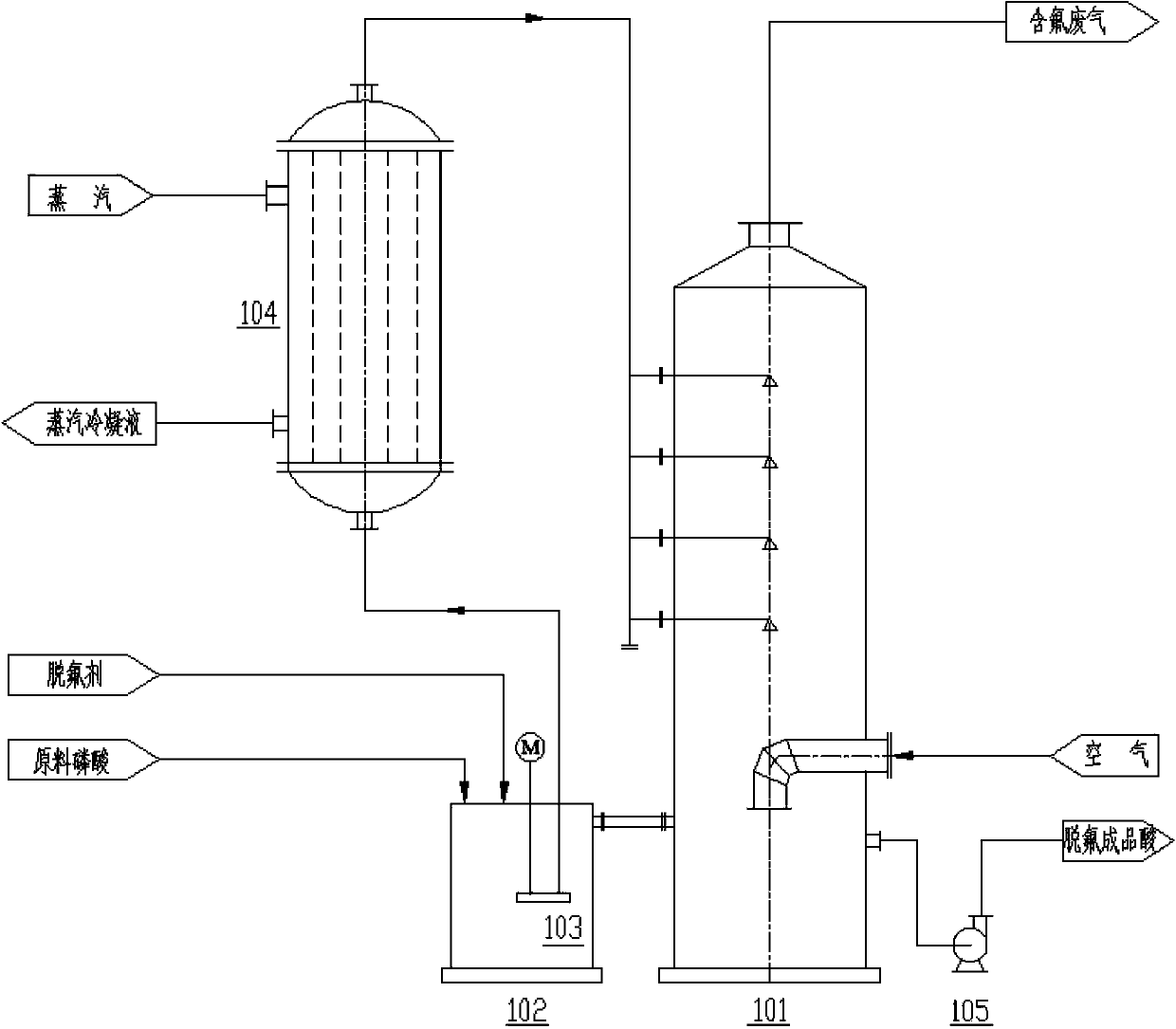

The invention discloses a tower type air stripping defluorination method for phosphoric acid. The method includes: firstly mixing the raw material fluorine-containing phosphoric acid, a defluorination agent and defluorinated phosphoric acid flowing out of the bottom of a defluorination tower to obtain low fluorine phosphoric acid, then heating the low fluorine phosphoric acid to 90-105DEG C, and leading it into the defluorination tower; spraying the low fluorine phosphoric acid in the tower through at least one layer of nozzles at the upper part inside the defluorination tower, introducing air from the lower part of the defluorination tower to make the low fluorine phosphoric acid and air fully contact to complete defluorination; discharging the fluorine-containing exhaust gas generated during defluorination from the top of the defluorination tower, mixing part or all of the defluorinated phosphoric acid generated at the bottom of a defluorination tower with the fluorine-containing phosphoric acid and the defluorination agent to obtain the low fluorine phosphoric acid to carry out defluorination circulation, and leading the other part of the defluorinated phosphoric acid out of the defluorination tower to obtain a finished phosphoric acid product. The process provided by the invention can reduce the fluorine content of phosphoric acid to a phosphorus-fluorine ratio (P2O5 / F) of greater than or equal to 260, and compared with the prior art, the fluorine content of the phosphoric acid is significantly reduced.

Description

technical field [0001] The invention belongs to the technical field of defluorination, and in particular relates to a tower-type air stripping phosphoric acid defluorination method. Background technique [0002] Since the 1950s, countries around the world have used wet-process phosphoric acid produced from phosphate rocks as a raw material to produce calcium phosphate salts as feed additives, among which calcium hydrogen phosphate is the main one. Feed grade phosphate is mainly calcium hydrogen phosphate (CaHPO 4 2H 2 O) DCP, calcium dihydrogen phosphate (Ca(H 2 PO 4 ) 2 ·H 2 O) MCP and tricalcium phosphate (Ca 3 (PO 4 ) 2 ·H 2 O) TCP. DCP and TCP are mainly used in the production of livestock and poultry feed, and MCP is mainly used in the production of aquatic feed. [0003] The source of phosphorus in feed-grade calcium hydrogen phosphate is mainly wet-process phosphoric acid. Generally, dilute phosphoric acid (with a concentration of 24% to 27%P) produced by a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B25/237

Inventor 孙国超孙菊萍李燕凤胡慧刘项

Owner SINOPEC NANJING ENG & CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com