Method for preparing lithium deuteride by using high-temperature direct manner

A lithium deuterium, direct method technology, applied in the intersection of material science and nuclear technology, can solve the problems of many lithium deuterium defects, small deuterium/lithium atomic ratio, insufficient deuterium absorption, etc., and achieves good product stability and preparation. The effect of simple and easy-to-buy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

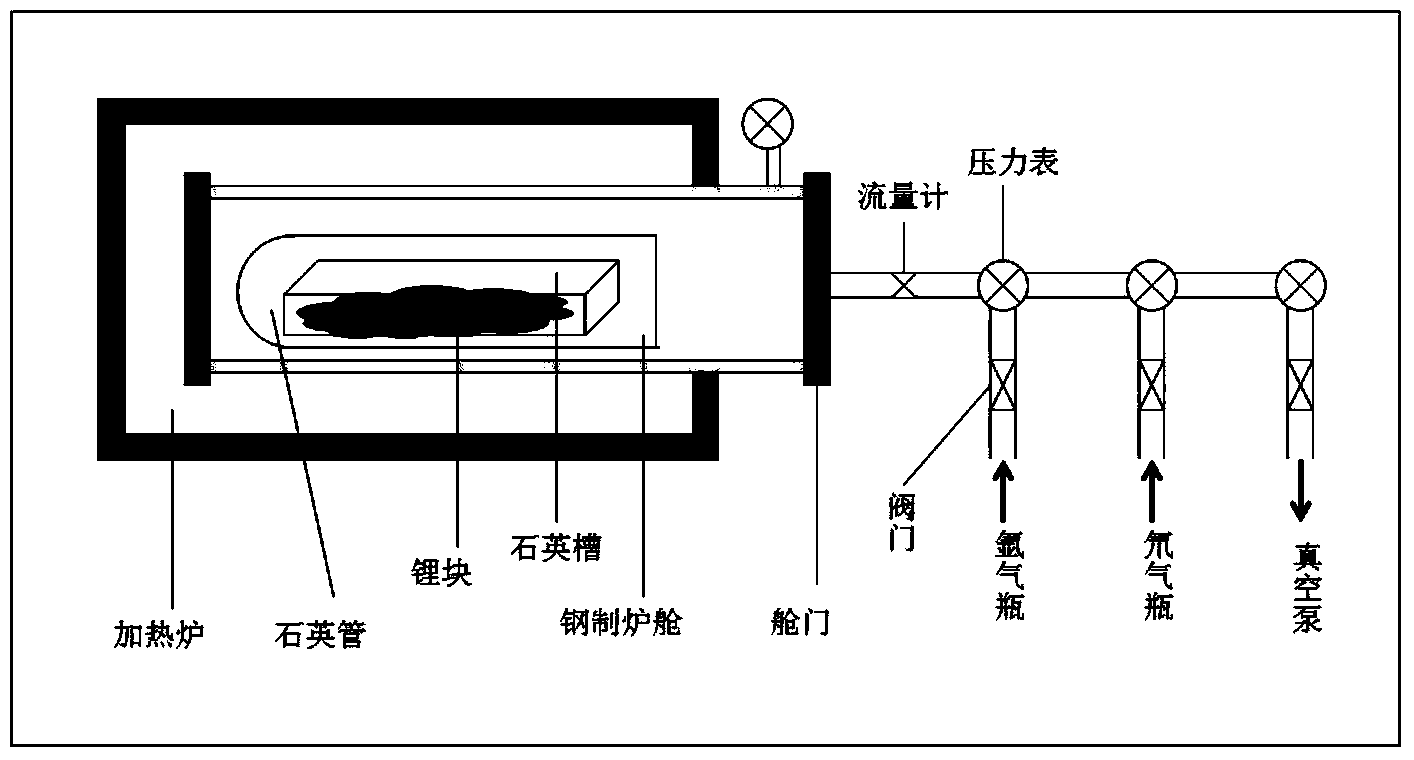

[0022] Under the protection of argon, cut the lithium block with a purity of 99.99% into small pieces with a particle size of 5mm, weigh 308g and place it in an open quartz tank, place the quartz tank in a glass tube made of quartz, and place the quartz tube in Heating the furnace cabin at high temperature and closing the furnace cabin quickly (such as figure 1 Shown); Pass in argon gas to replace the gas in the cabin, pump the pressure in the cabin to a negative pressure of 0.021MPa, pass in 99.999% high-purity deuterium gas, pump it again to a vacuum of 0.014MPa, and repeat the operation 2 times; Maintain the above-mentioned vacuum degree, and rapidly raise the temperature to 175°C at a heating rate of 15°C / min; then pass deuterium gas at a flow rate of 5441ml / min, and react for 30 minutes; continue to raise the temperature at a heating rate of 5°C / min over 6 minutes To 195°C, react for 50 minutes; control the deuterium flow rate unchanged, and raise the temperature in the f...

Embodiment 2

[0024] Under the protection of argon, cut the lithium block with a purity of 99.99% into small pieces with a particle size of 10mm, weigh 703g and place it in an open quartz tank, place the quartz tank in a glass tube made of quartz, and place the quartz tube in Heating the furnace cabin at high temperature and closing the furnace cabin quickly (such as figure 1 Shown); Pass in argon gas to replace the gas in the cabin, pump the pressure in the cabin to a negative pressure of 0.020MPa, pass in 99.999% high-purity deuterium gas, and pump again to a vacuum of 0.015MPa, repeat the operation 3 times; Maintain the above-mentioned vacuum degree and quickly raise the temperature to 167°C at a heating rate of 10°C / min; then pass deuterium gas at a flow rate of 11279ml / min for 42 minutes; After 21 minutes, the temperature was raised to 216°C, and the reaction was carried out for 50 minutes; the deuterium flow rate was kept constant, and the temperature in the furnace cabin was raised t...

Embodiment 3

[0026] Under the protection of argon, cut a lithium block with a purity of 99.99% into small pieces with a particle size of 2mm, weigh 1253g and place it in an open quartz tank, place the quartz tank in a glass tube made of quartz, and place the quartz tube in Heating the furnace cabin at high temperature and closing the furnace cabin quickly; introducing argon gas to replace the gas in the cabin, pumping the cabin pressure to a negative pressure of 0.018MPa, feeding 99.999% high-purity deuterium gas, and pumping again to a vacuum degree of 0.013MPa, repeat the operation 3 times; maintain the above vacuum degree, raise the temperature to 161°C at a heating rate of 20°C / min; After 4 minutes at a heating rate of 10°C / min, the temperature was raised to 185°C, and then reacted for 70 minutes; the deuterium flow rate was kept constant, and the temperature in the furnace cabin was raised to 574°C at a speed of 15°C / min for 35 minutes, and then the temperature was stopped. Constant t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com