Fluidized bed sludge drying system

A sludge drying and fluidized bed technology, which is applied in dehydration/drying/concentrated sludge treatment, energy wastewater treatment, etc., can solve the problem of affecting the drying effect of sludge particles, high energy consumption of the air preheater, and sludge lumps The problem of different sizes can achieve the effect of improving the drying effect, prolonging the service life and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

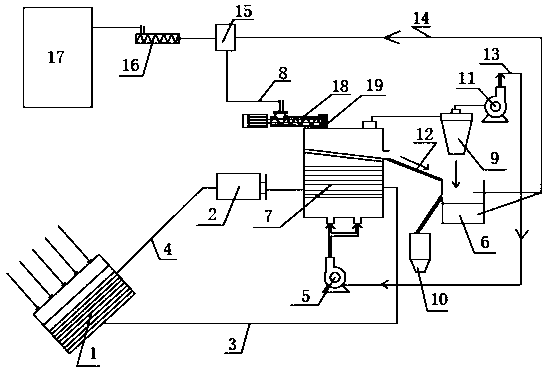

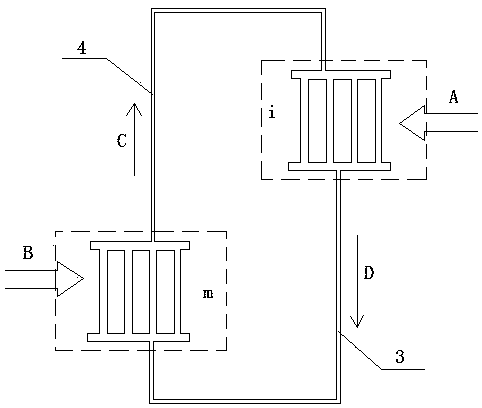

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

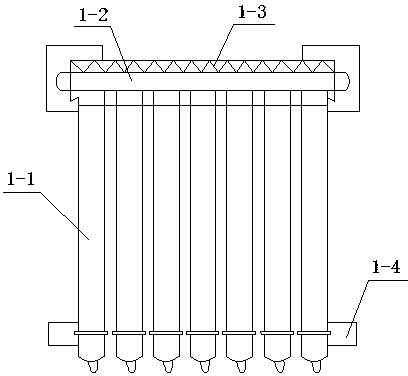

[0027] Such as figure 1 As shown, the present invention includes a sludge mixing device, a sludge breaking device, a fluidized bed 7, a heater and a sludge collecting device. The sludge mixing device is used to uniformly mix sludge in different states into a viscous state. The sludge disintegration device is connected with the sludge mixing device through a viscous sludge conveying pipeline 8, and is used for converting the sludge in a viscous state into a lumpy sludge. The fluidized bed 7 is used to dry the lumpy sludge, and the heater provides heat for the working medium in the heat pipe heat exchanger of the fluidized bed 7, and the sludge collection device separates the dried lumpy sludge, Gather together.

[0028] The fluidized bed 7 includes a heat pipe heat exchanger layer, a sludge drying layer and an air box layer, the inlet of the air box layer is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com