An airgel composite material for high temperature insulation

A composite material and airgel technology, which is applied in the field of high-temperature heat-insulating airgel composite materials, can solve problems such as complex use environments, achieve high porosity and specific surface area, improve high-temperature heat insulation performance, and good heat insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

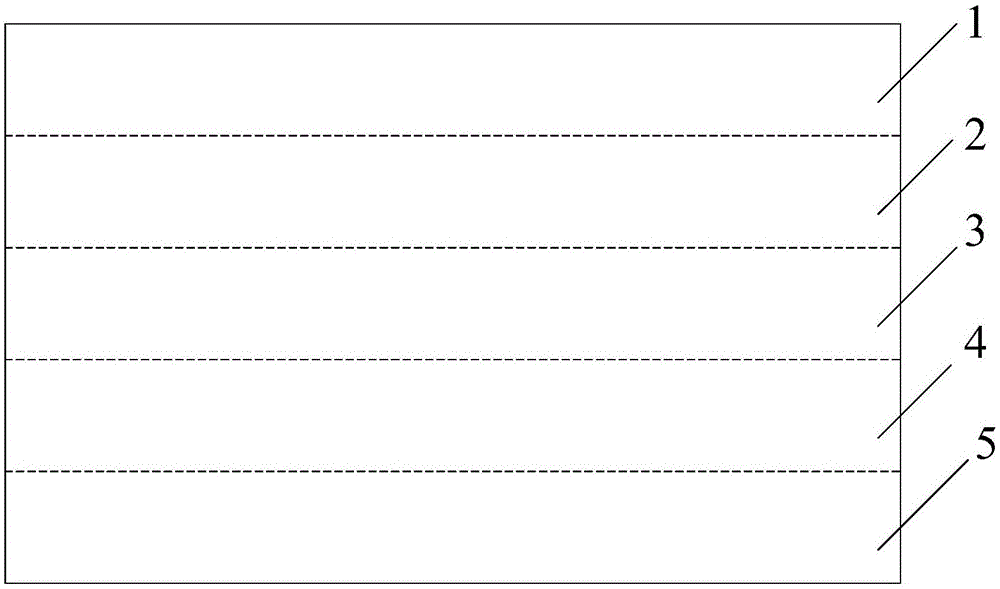

[0022] Doped SiO 2 The airgel composite material is distributed layer by layer from the outer surface to the inside as the first doped layer, the second doped layer and the third doped layer, and the first doped layer is carbon black-SiO 2 Airgel composite material, the particle size of carbon black is 2.7 μm, and the mass percentage of carbon black in the first doped layer is 45%; the second doped layer is SiC-SiO 2 Airgel composite material, the particle size of SiC is 3.2 μm, the mass percentage of SiC in the second doped layer is 80%; the third doped layer is SiC-SiO 2 In the airgel composite material, the particle size of SiC is 2.6 μm, and the mass percentage of SiC in the third doped layer is 84%.

[0023] The resulting doped SiO 2 The thermal conductivity of the airgel composite is 0.042W / m K at 300°C, 0.047W / m K at 600°C, 0.054W / m K at 900°C, and 0.054W / m K at 1200°C. The thermal conductivity is 0.058W / m·K.

Embodiment 2

[0025] The SiO2 airgel composite material is distributed layer by layer from the outer surface to the inside as the first doped layer, the second doped layer, the third doped layer and the fourth doped layer, and the first doped layer is carbon black- SiO 2 Airgel composite material, the particle size of carbon black is 2.9 μm, and the mass percentage of carbon black in the first doped layer is 42%; the second doped layer is SiC-SiO 2 Airgel composite material, the particle size of SiC is 3.5 μm, the mass percentage of SiC in the second doped layer is 75%; the third doped layer is SiC-SiO 2 Airgel composite material, the particle size of SiC is 3.1 μm, the mass percentage of SiC in the third doped layer is 81%; the fourth doped layer is SiC-SiO 2 In the airgel composite material, the particle size of SiC is 2.5 μm, and the mass percentage of SiC in the fourth doping layer is 85%.

[0026] The resulting doped SiO 2 The thermal conductivity of the airgel composite material is...

Embodiment 3

[0028] Doped SiO 2 The airgel composite material is distributed layer by layer from the outer surface to the inside and is arranged as the first doped layer, the second doped layer, the third doped layer, the fourth doped layer and the fifth doped layer, the first doped layer layer is carbon black-SiO 2 Airgel composite material, the particle size of carbon black is 2.8 μm, and the mass percentage of carbon black in the first doped layer is 43.5%; the second doped layer is SiC-SiO 2 Airgel composite material, the particle size of SiC is 3.4 μm, the mass percentage of SiC in the second doped layer is 77%; the third doped layer is SiC-SiO 2 Airgel composite material, the particle size of SiC is 3.0 μm, the mass percentage of SiC in the third doped layer is 79%; the fourth doped layer is SiC-SiO 2 Airgel composite material, the particle size of SiC is 2.8 μm, the mass percentage of SiC in the fourth doped layer is 82%; the fifth doped layer is SiC-SiO 2 In the airgel composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com