Preparation method for fluorescent powder with structure similar to Si3N4 and prepared fluorescent powder

A fluorescent powder, -si3n4 technology, applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of harsh synthesis conditions, poor reactivity, residues, etc., to shorten the production cycle, meet the crystallinity and light efficiency, and improve the synthesis reaction speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The Si-like prepared in this example 3 N 4 The chemical formula of structural phosphor is (Sr 0.999 / 3 Al 0.81 / 3 Si 4 / 3 ) 3 (N 6.8 / 4 ) 4 :0.001Eu 2+ . Its preparation method is: weigh an appropriate amount of Sr according to the stoichiometric ratio of each element in the chemical formula 3 N 2 、Si 3 N 4 , AlN, EuN as raw materials and grind and mix evenly, where Si 3 N 4 The raw material is made of α-Si 3 N 4 and β-Si 3 N 4 Composed of, and β-Si 3 N 4 and α-Si 3 N 4 The molar ratio is 0.005. The mixed raw materials were put into a crucible, and then kept at 1650° C. for 8 hours in a nitrogen atmosphere. After the reaction is completed, take out the product when the temperature drops below 100°C, and finally perform crushing, washing, drying and other treatments to obtain a Si-like 3 N 4 Structured Phosphors. The light color data such as the main peak position and relative luminous brightness of the phosphor powder are shown in Table 1.

Embodiment 2-6

[0030] The fluorescent powder preparation method of embodiment 2-6 is substantially the same as embodiment 1, and is (M a1 Al b1 Si cl ) 3 (N d1 ) 4 :x 1 Eu 2+ The preparation method of phosphor, the difference is the element composition in the chemical formula and the β-Si in the raw material 3 N 4 and α-Si 3 N 4 The molar ratio is shown in Table 1.

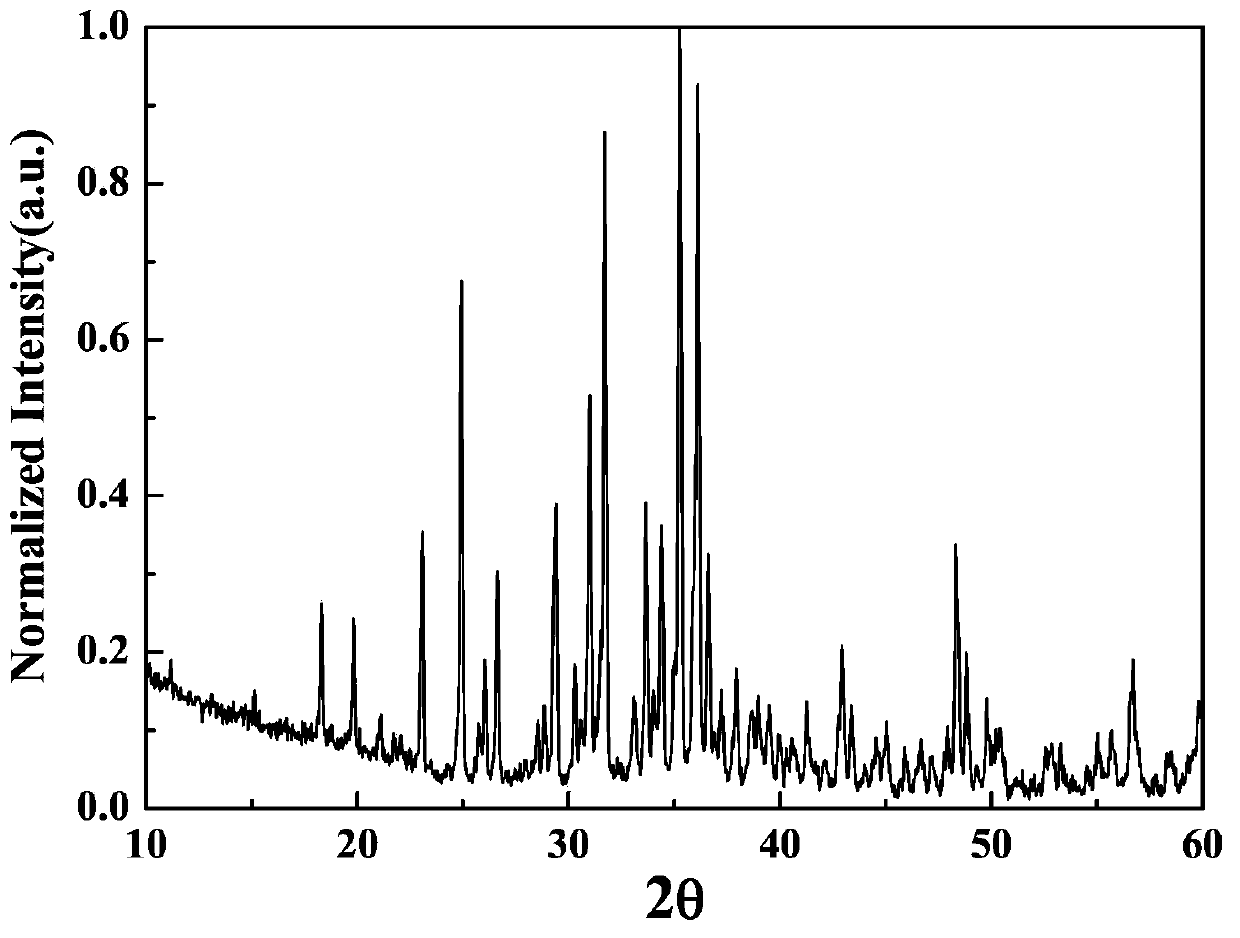

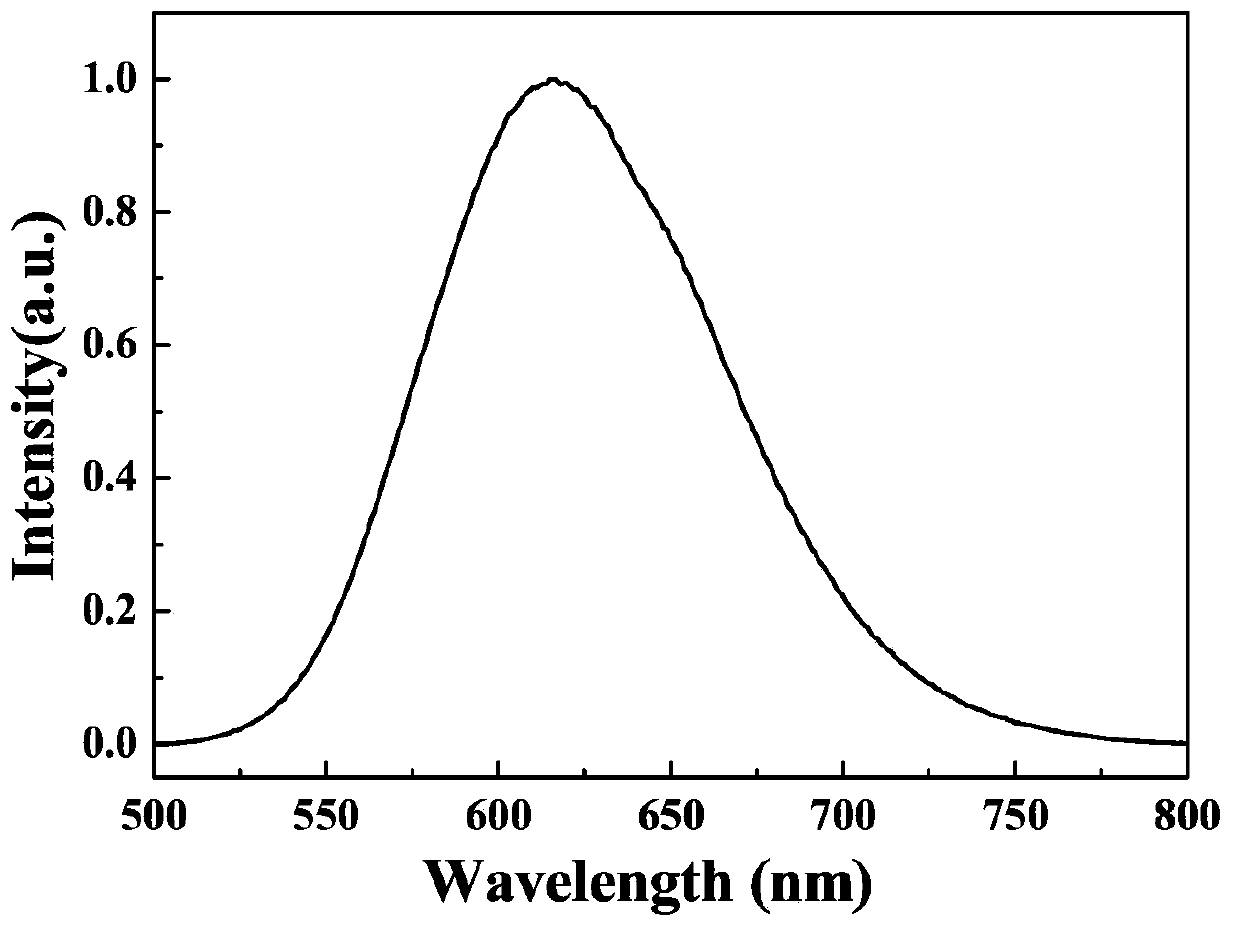

[0031] The light color data such as the main peak position and relative luminous brightness of the phosphor powders of these embodiments are shown in Table 1. Apply XRD, SEM and fluorescence spectrum to characterize embodiment 5 fluorescent powder, the result that obtains is respectively as follows figure 1 , figure 2 and image 3 shown. From figure 1 It can be seen that the prepared phosphor has a single phase (Sr 0.9 / 3 Al 1.2 / 3 Si 4 / 3 ) 3 (N 7.2 / 4 ) 4 :0.1Eu 2+ , and, from figure 2 It can be seen that the crystallinity of the phosphor powder is good, and the crystal morphology is clear and columnar. F...

Embodiment 7

[0033] The Si-like prepared in this example 3 N 4 The chemical formula of structural phosphor is (Sr 0.95 / 3 Ca 0.25 / 3 Al 1 / 3 Si 3.81 / 3 ) 3 (N 6.98 / 4 ) 4 :0.15Eu 2+ . Its preparation method is: weigh an appropriate amount of Ca according to the stoichiometric ratio of each element in the chemical formula 3 N 2 、Sr 3 N 2 、Si 3 N 4 , AlN, EuN as raw materials and grind and mix evenly, where Si 3 N 4 The raw material is made of α-Si 3 N 4 and β-Si 3 N 4 Composed of, and β-Si 3 N 4 and α-Si 3 N 4 The molar ratio is 0.5. The mixed raw materials were put into a crucible, and then kept at 1650° C. for 8 hours in a nitrogen atmosphere. After the reaction is completed, take out the product when the temperature drops below 100°C, and finally perform crushing, washing, drying and other treatments to obtain a Si-like 3 N 4 Structured Phosphors. The light color data such as the main peak position and relative luminous brightness of the phosphor powder are shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com