LED display screen

A technology of LED display screen and LED light board, which is applied in cooling/heating devices of lighting devices, lighting devices, light sources, etc., can solve the cost of raw materials for aluminum radiators, high maintenance costs, unsatisfactory heat dissipation effects, and post-maintenance Not in time and other problems, to achieve the effect of light weight, improved heat dissipation effect, increased heat exchange area and heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1. Different from the existing LED display screen that uses fans for heat dissipation, a second heat dissipation device is added on the integrated circuit welding surface of the LED lamp board. The second heat dissipation device is a layered heat dissipation device made of thermomagnetic working fluid The thickness of the second radiator is 0.1-0.2mm. The heat dissipation effect of the thermomagnetic radiator is much better than that of ordinary copper radiators, aluminum radiators and fans, and the average power consumption per watt is only It needs 8-20g of thermal magnetic working fluid material, which is only equivalent to 1 / 5-1 / 10 of the aluminum heat sink. It is light in weight, low in carbon emissions in the material manufacturing process, energy-saving and environmentally friendly, and at the same time improves the performance of the LED display. The heat dissipation effect prolongs the service life of the LED display.

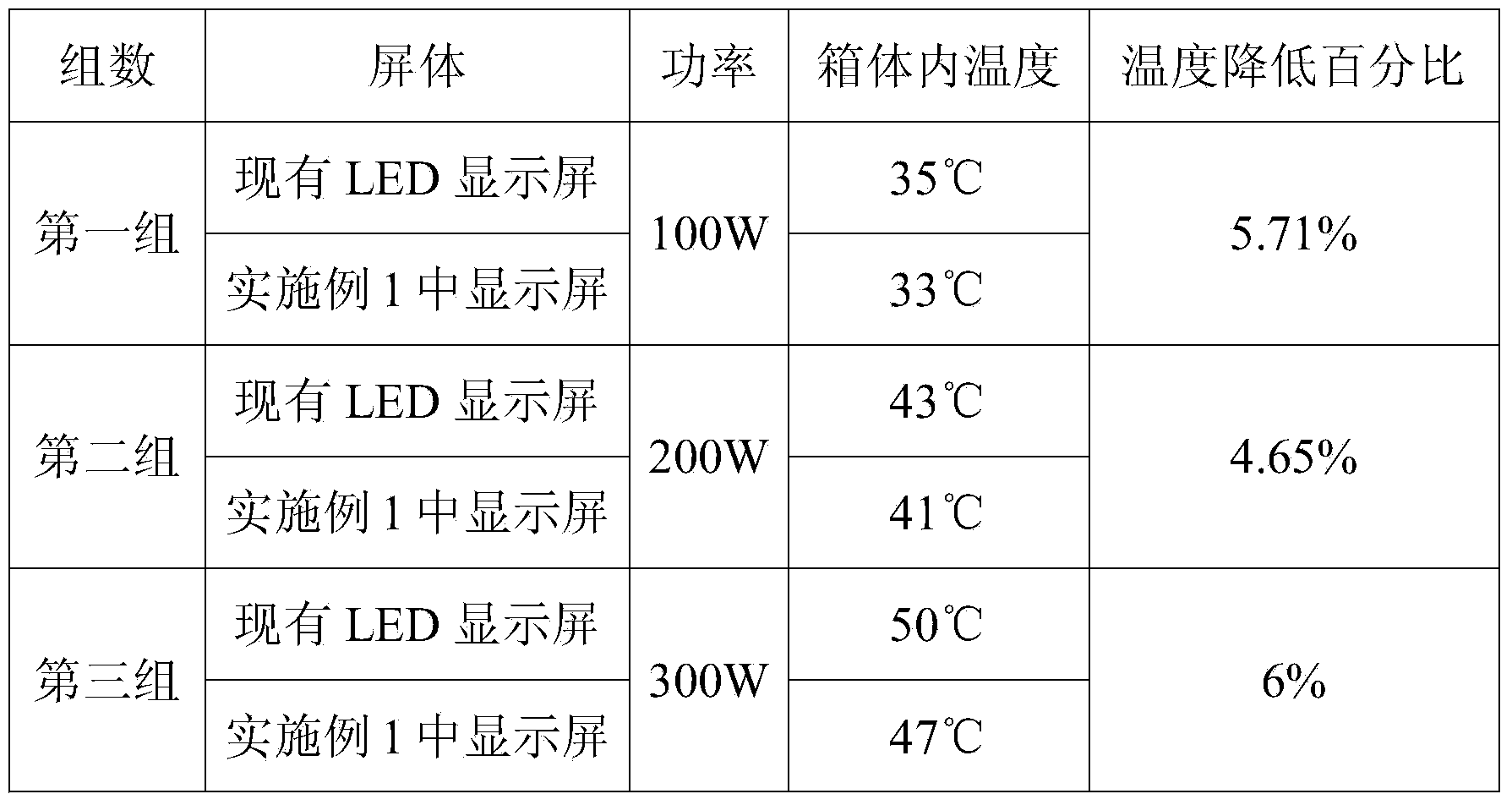

[0017] Three groups of experim...

Embodiment 2

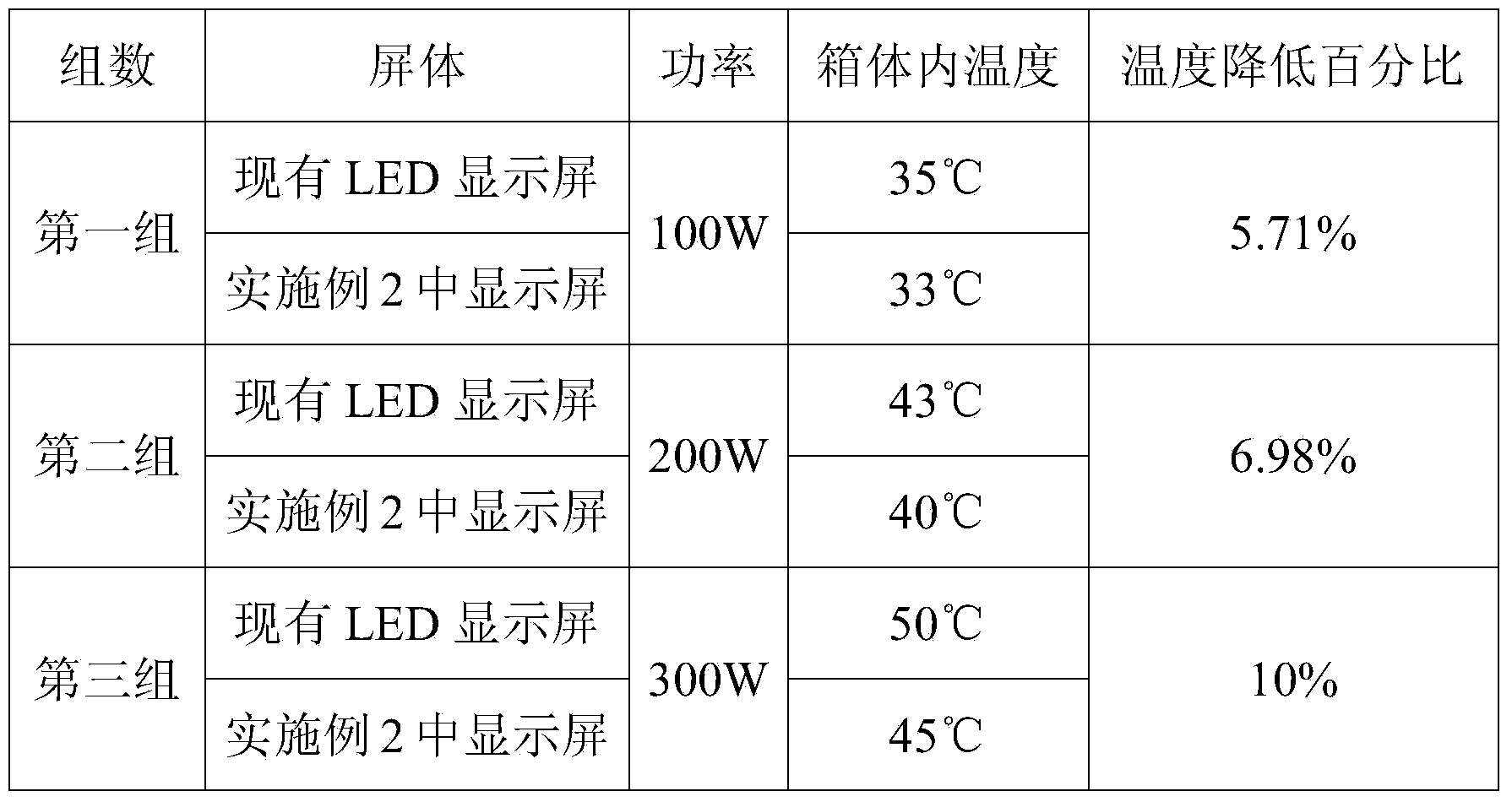

[0021] Embodiment 2. What is different from the existing LED display screen that uses a fan to dissipate heat is that the first heat dissipation device is not a fan but a thermomagnet radiator made of thermomagnetic working fluid material. The first heat dissipation device is arranged on the rear cover 3 The inner surface of the first heat sink has a thickness of 0.1-0.2mm. Compared with fans, the thermomagnetic working fluid material itself does not generate power consumption and heat, saving energy. Compared with aluminum radiators, the average power consumption per watt is only 8-20g of thermomagnetic working fluid material, which is only equivalent to 1 / 5 to 1 / 10 of the aluminum radiator, the cost of the thermomagnetic working fluid material is slightly lower than that of ordinary aluminum, and at the same time it has the characteristics of light weight, less consumables, and high processing efficiency. Therefore, the LED display screen The total cost is greatly reduced. ...

Embodiment 3

[0026] Embodiment 3, what is different from the existing LED display screens that use fans to dissipate heat is that the first heat dissipation device is not a fan, but a layered thermomagnet radiator made of thermomagnetic working fluid material, the first heat dissipation device is set On the inner surface of the rear cover 3, the thickness of the first heat sink is 0.1-0.2 mm; at the same time, a second heat sink is added on the integrated circuit welding surface of the LED lamp board, and the second heat sink is made of a thermomagnetic working fluid material. A layered thermomagnet radiator with a thickness of 0.1-0.2 mm is formed.

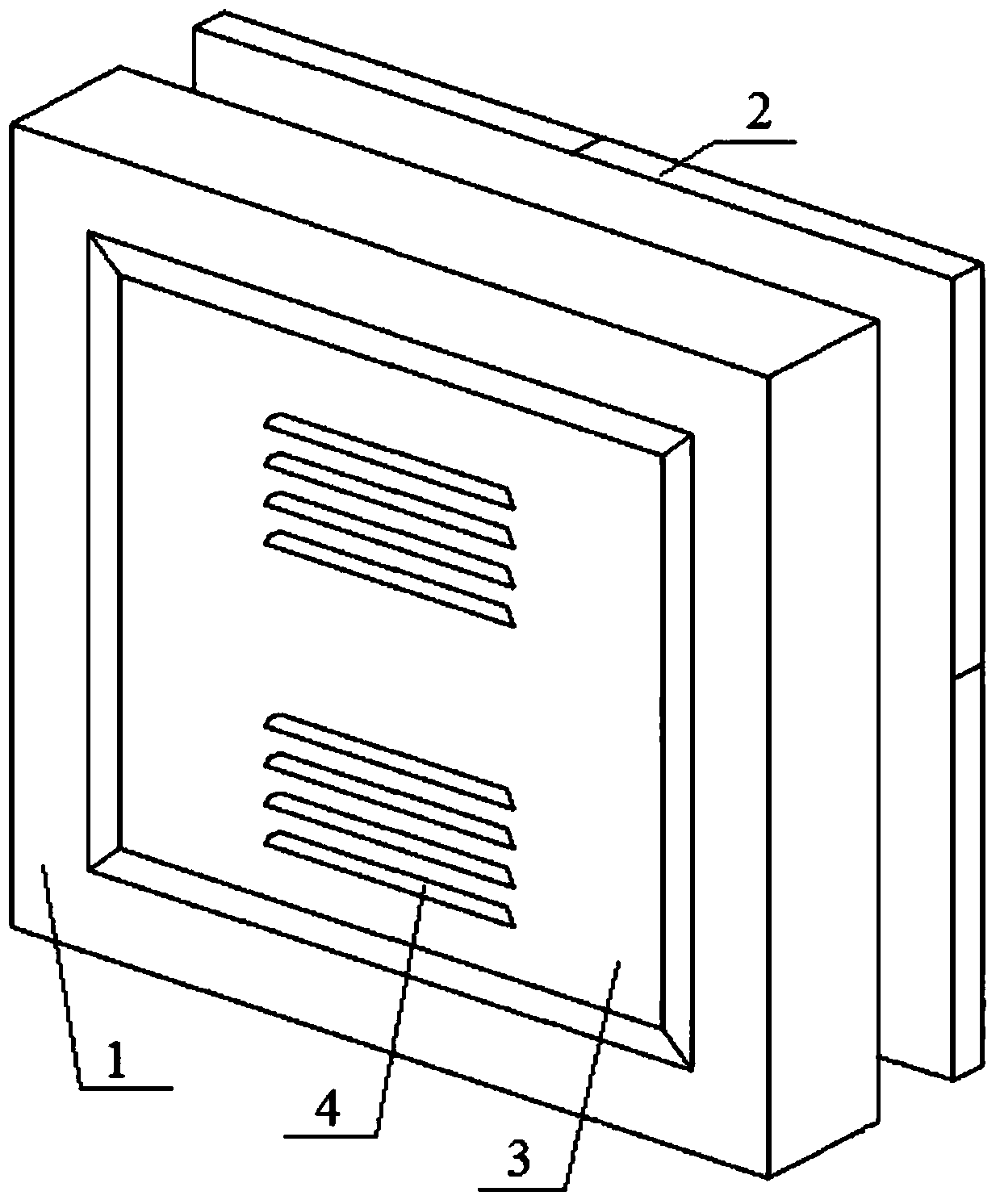

[0027] Such as figure 1 As shown, an LED display screen includes a box body 1, a module 2, a power supply, and a control box, and the module 2, power supply, and control box are all fixedly connected to the box body 1, and the power supply is a regulated power supply from AC to DC. The power factor of the power supply is greater than 0.95, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com