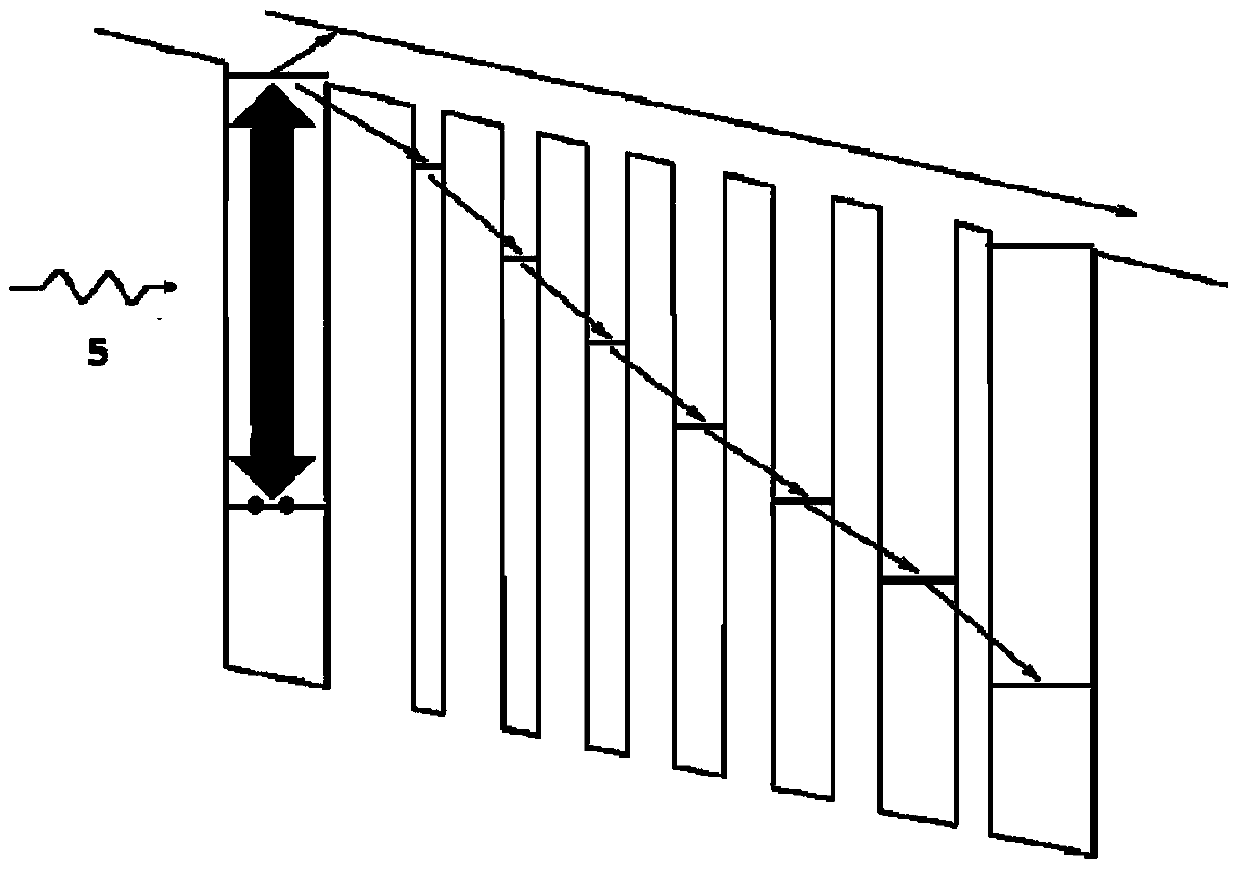

Potential barrier cascading quantum well infrared detector

A technology of infrared detectors and quantum wells, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of device detection rate decrease, increase dark current, etc., achieve high quantum efficiency and response rate, and improve quantum efficiency and response The effect of high efficiency, easy and accurate output and reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

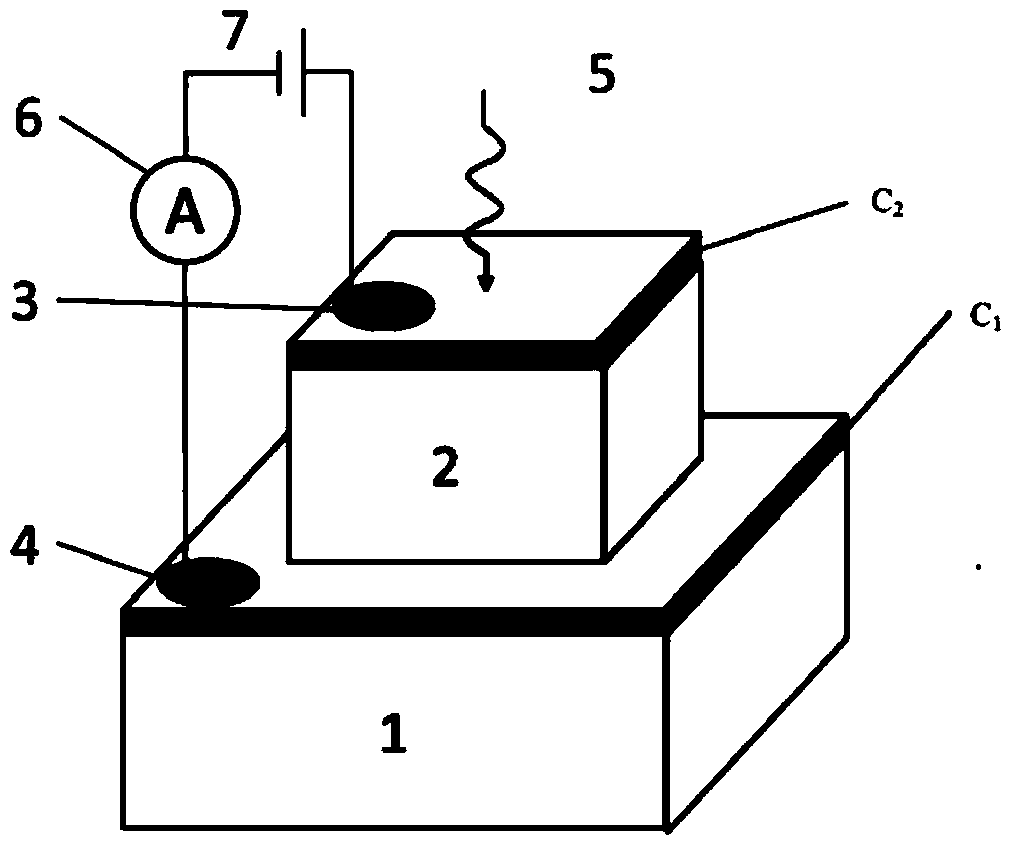

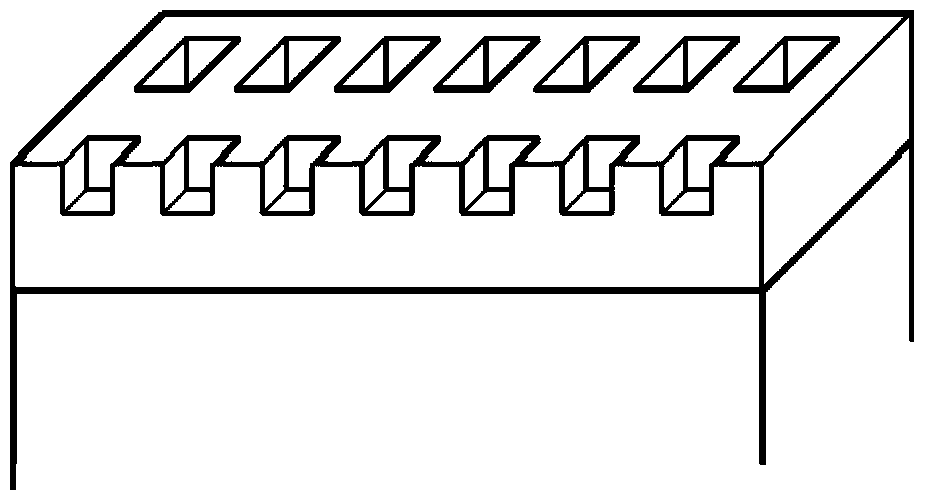

[0028] (1) Growth of thin film materials for multiple quantum well chips:

[0029] The following structure is sequentially grown on the GaAs substrate 1 by molecular number epitaxy (MBE), C 1 For GaAs:Si, the concentration is 10 18 / cm 3 , with a thickness of 0.5 μm; L 1 for Al 0.16 Ga 0.84 As, 40nm thick; QW 1 For GaAs:Si, the concentration is 10 17 / cm 3 , with a thickness of 6.8nm; L 1 ’ for Al 0.16 Ga 0.84 As, with a thickness of 5.65nm; QW 2 For GaAs, the thickness is 2nm; L 2 ’ for Al 0.16 Ga 0.84 As, with a thickness of 3.96nm; QW 3 For GaAs, the thickness is 2.3nm; L 3 ’ for Al 0.16 Ga 0.84 As, with a thickness of 3.1nm; QW 4 For GaAs, the thickness is 2.8nm; L 4 ’ for Al 0.16 Ga 0.84 As, with a thickness of 3.1nm; QW 5 For GaAs, the thickness is 3.3nm; L 5 ’ for Al 0.16 Ga 0.84 As, with a thickness of 3.1nm; QW 6 For GaAs, the thickness is 4nm; L 6 ’ for Al 0.16 Ga 0.84 As, with a thickness of 3.1nm; QW 7 For GaAs, the thickness is 5nm; t...

example 2

[0036] (1) Growth of thin film materials for multiple quantum well chips:

[0037] The following structure is sequentially grown on the GaAs substrate 1 by molecular number epitaxy (MBE), C 1 For GaAs:Si, the concentration is 10 18 / cm 3 , with a thickness of 0.75 μm; L 1 for Al 0.15 Ga 0.85 As, 50nm thick; QW 1 For GaAs:Si, the concentration is 10 17 / cm 3 , with a thickness of 7.6nm; L 1 ’ for Al 0.15 Ga 0.85 As, with a thickness of 5.8nm; QW 2 For GaAs, the thickness is 2.2nm; L 2 ’ for Al 0.15 Ga 0.85 As, with a thickness of 4.1nm; QW 3 For GaAs, the thickness is 2.5nm; L 3 ’ for Al 0.15 Ga 0.85 As, with a thickness of 3.3nm; QW 4 For GaAs, the thickness is 3nm; L 4 ’ for Al 0.15 Ga 0.85 As, with a thickness of 3.3nm; QW 5 For GaAs, the thickness is 3.5nm; L 5 ’ for Al 0.15 Ga 0.85 As, with a thickness of 3.3nm; QW 6 For GaAs, the thickness is 4.2nm; L 6 ’ for Al 0.15 Ga 0.85 As, with a thickness of 3.3nm; QW 7 For GaAs, the thickness is 5.2nm...

example 3

[0044] (1) Growth of thin film materials for multiple quantum well chips:

[0045] The following structure is sequentially grown on the GaAs substrate 1 by molecular number epitaxy (MBE), C 1 For GaAs:Si, the concentration is 10 18 / cm 3 , with a thickness of 1 μm; L 1 for Al 0.14 Ga 0.86 As, 60nm thick; QW 1 For GaAs:Si, the concentration is 10 17 / cm 3 , with a thickness of 8nm; L 1 ’ for Al 0.14 Ga 0.86 As, 6nm thick; QW 2 For GaAs, the thickness is 2.4nm; L 2 ’ for Al 0.14 Ga 0.86 As, with a thickness of 4.3nm; QW 3 For GaAs, the thickness is 2.7nm; L 3 ’ for Al 0.14 Ga 0.86 As, with a thickness of 3.5nm; QW 4 For GaAs, the thickness is 3.2nm; L 4 ’ for Al 0.14 Ga 0.86 As, with a thickness of 3.5nm; QW 5 For GaAs, the thickness is 3.7nm; L 5 ’ for Al 0.14 Ga 0.86 As, with a thickness of 3.5nm; QW 6 For GaAs, the thickness is 4.4nm; L 6 ’ for Al 0.14 Ga 0.86 As, with a thickness of 3.5nm; QW 7 For GaAs, the thickness is 5.4nm; then QW 1 to QW ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com