A kind of waste battery recycling system and recycling method

A waste battery and recycling system technology, applied in the field of comprehensive utilization of resources, can solve problems such as low solubility, recovery rate of less than 2%, and affecting treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

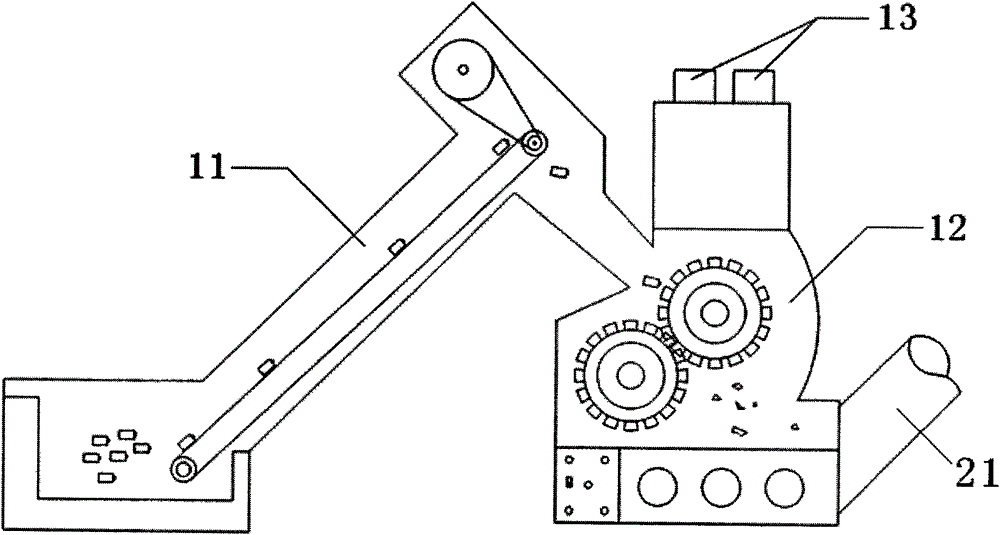

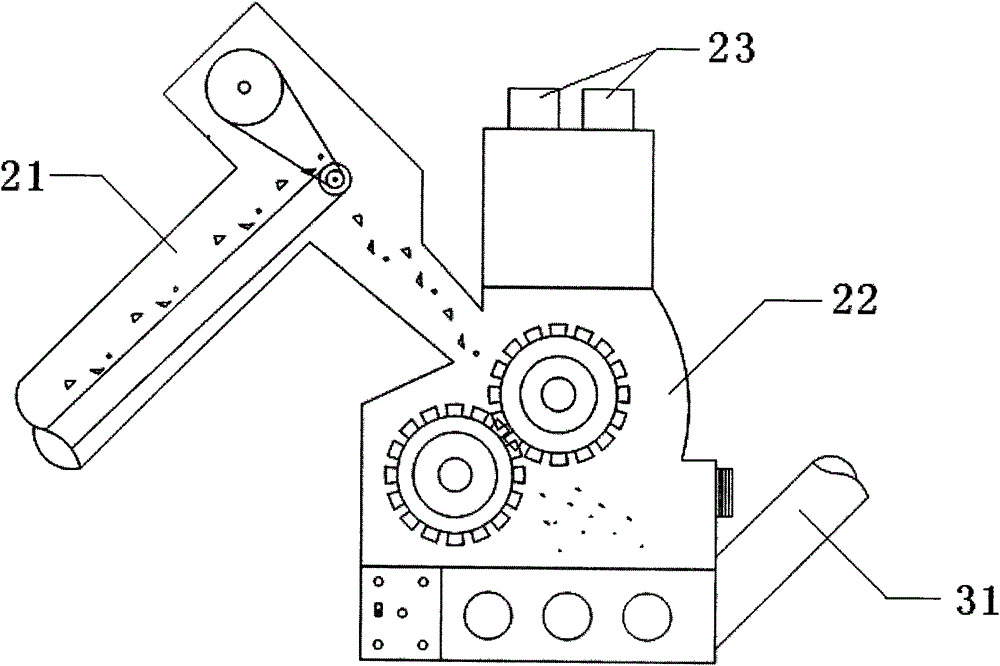

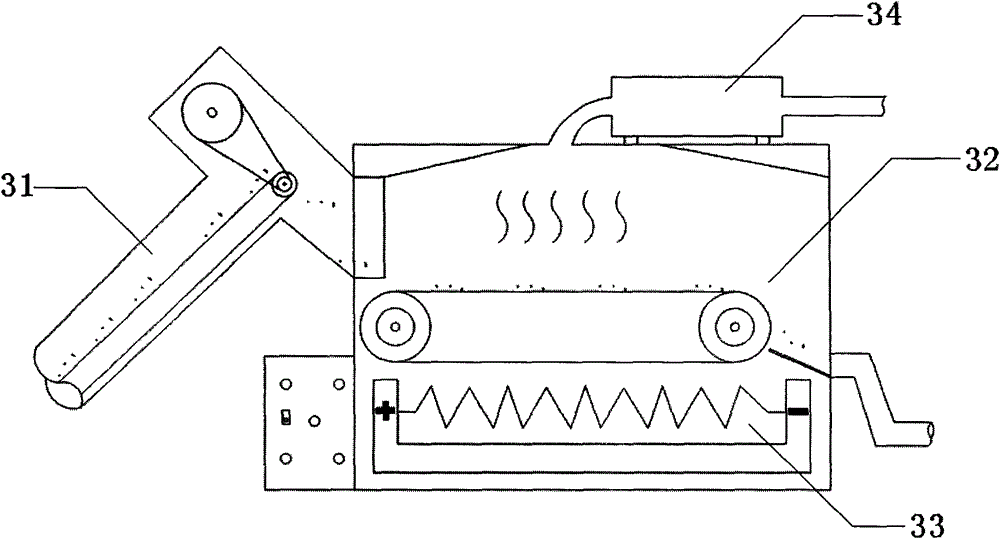

[0040] Such as Figure 1 to Figure 11As shown, a waste battery recycling system, the system mainly includes a waste battery feeding bin connected in sequence, a 4500*450mm (outer diameter) horizontal + slope skirt conveyor belt 11, a 20HP primary crusher 12, and a 4000*450mm (outer diameter) horizontal + slope skirt conveyor belt 21, 20HP secondary crusher 22, 4500*450mm (outer diameter) parallel + climbing skirt conveyor belt 31, 5000*600mm / 5 layers 200 degree drying conveyor 32. Storage bin for drying and removing mercury battery debris, 2000*Φ159mm screw conveyor 41, 1500*700mm single-layer vibrating screen 51, 1800*Φ159mm screw conveyor, 1500*700mm vibrating screen 71, 4500*550mm (outer diameter) Horizontal + slope skirt magnetic separation conveyor belt 72, biaxial crusher, 1500*700mm single-layer vibrating screen, 4000*450mm (outer diameter) parallel + climbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com