Method for recycling metal elements in waste lithium battery positive electrode material

A technology for waste lithium batteries and positive electrode materials, which is applied in the field of recycling metal elements in the positive electrode materials of waste lithium batteries, and can solve the problems of high cost, waste liquid and waste gas discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108]A kind of method for reclaiming metal element cobalt of anode material in the waste lithium battery, carries out according to the following steps:

[0109] Step 1: Routine pretreatment of spent lithium batteries

[0110] 1) Put the used mobile phone lithium battery in saturated salt water for 12 hours to completely release the residual power.

[0111] 2) Take the battery out of the salt water, rinse it with pure water, and dry it, then disassemble the battery to obtain the positive electrode sheet.

[0112] 3) Place the positive electrode sheet in a tube furnace, and perform vacuum cracking at 400° C. to remove the binder. Then, the positive electrode sheet is cooled to room temperature, and the positive electrode material is peeled off from the positive electrode sheet.

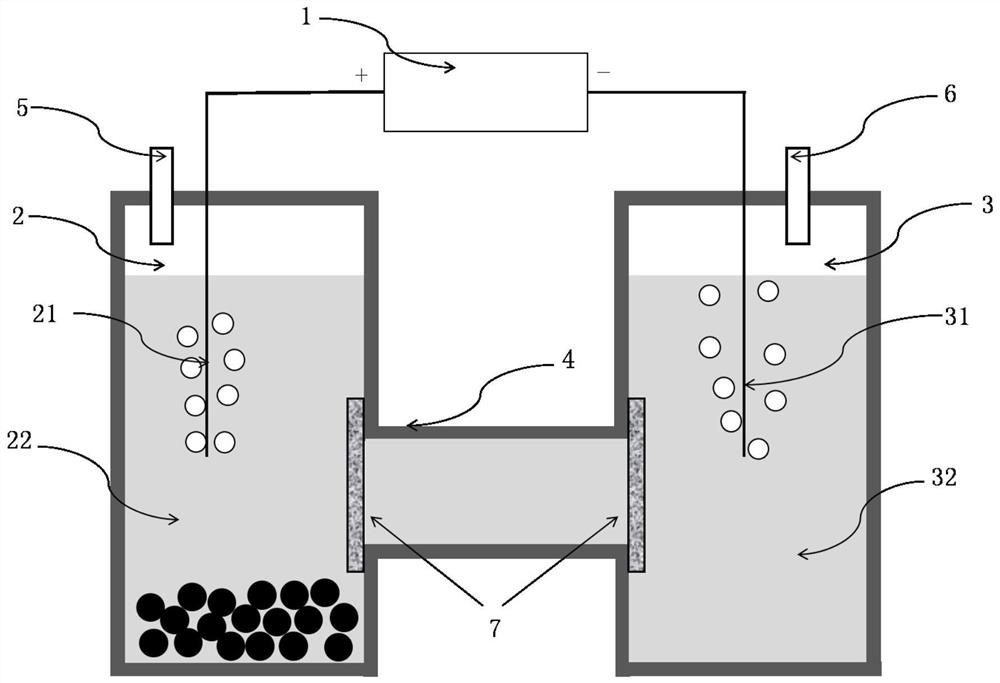

[0113] Step 2: Assemble the Electrolytic Cell

[0114] 1) Add about 60ml of 1mol / L NaNO 3 The aqueous electrolyte is added to the H-type electrolytic cell. The volume of the anode electrolysis cha...

Embodiment 2

[0124] A kind of method for reclaiming metal element cobalt of anode material in the waste lithium battery, carries out according to the following steps:

[0125] Step 1: Routine pretreatment of spent lithium batteries

[0126] With embodiment 1. The difference is that the stripped positive electrode material is calcined at 800°C to remove the carbon therein.

[0127] Step 2: Assemble the Electrolytic Cell

[0128] With embodiment 1. The difference is that both the anode and the cathode use platinum wires with a diameter of 1mm.

[0129] Step 3: Electrolysis

[0130] With embodiment 1. The difference is: the experimental temperature is set to 80°C.

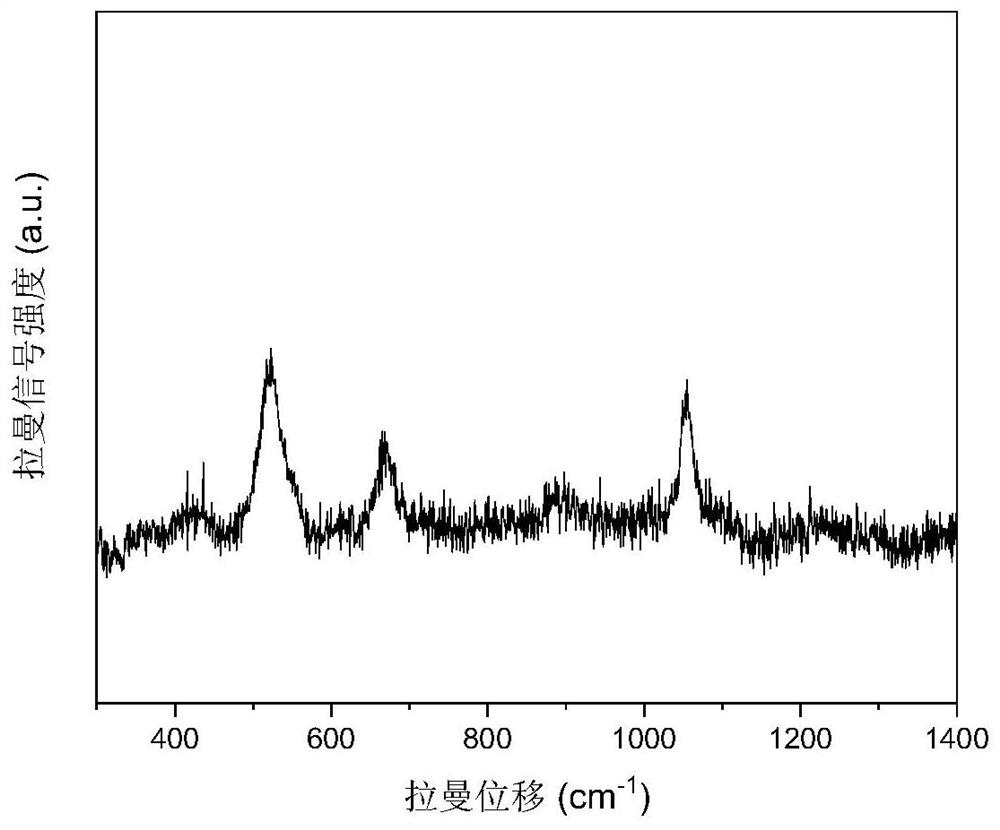

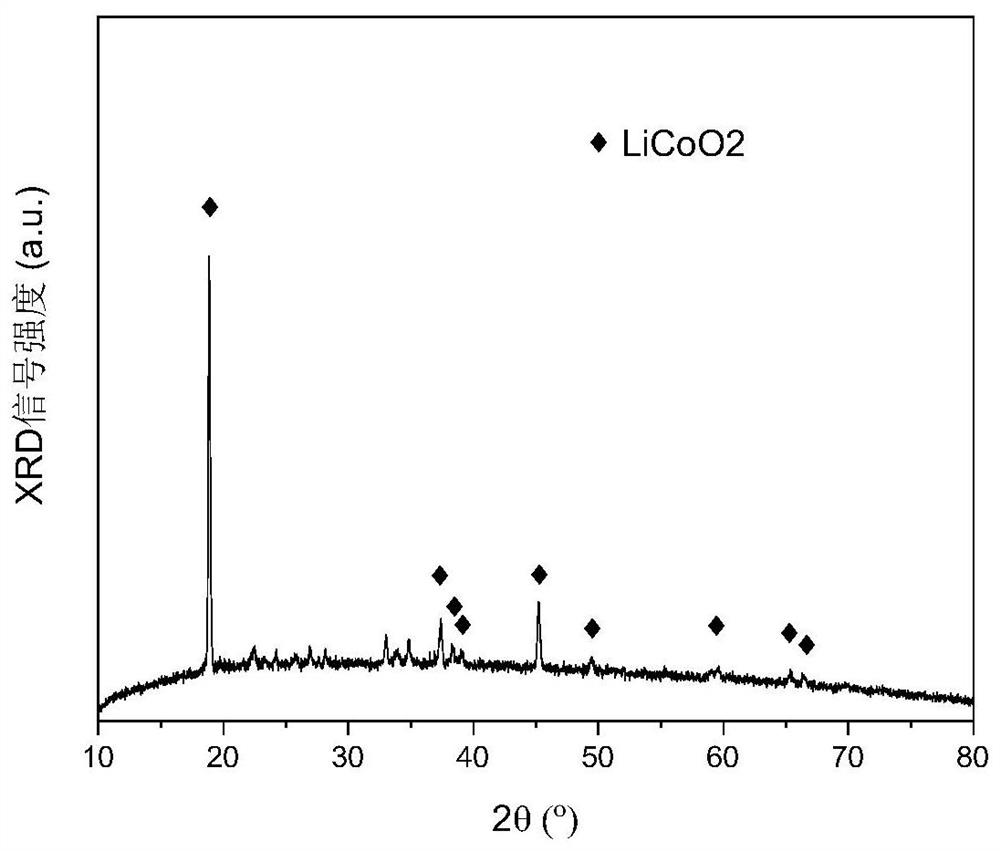

[0131] Step 4: Extraction of valuable metal element cobalt

[0132] The precipitate generated in the cathode electrolysis chamber 32 on the cathode side was separated by suction filtration, washed with water, and dried in a drying oven at 100° C. for 2 hours. The obtained powder was pink and had a mass of about 0.05 g. Th...

Embodiment 3

[0134] A kind of method for reclaiming metal element cobalt of anode material in the waste lithium battery, carries out according to the following steps:

[0135] step 1:

[0136] Routine pretreatment of used lithium batteries

[0137] With embodiment 1.

[0138] Step 2:

[0139] With embodiment 1. The difference is: the volume of the anode electrolysis chamber 22 on the anode side of the H-type electrolytic cell is about 50 ml, and the volume of the cathode electrolysis chamber 32 on the cathode side is about 50 ml. The volume of the communicating chamber 4 of the two anode electrolysis chambers 22 is approximately 10 ml. Add about 100ml of 1mol / L NaNO 3 The aqueous electrolyte is added to the H-type electrolytic cell.

[0140] Step 3: Electrolysis

[0141] With embodiment 1.

[0142] Step 4: Extraction of valuable metal element cobalt

[0143] The precipitate generated in the cathode electrolysis chamber 32 on the cathode side was separated by suction filtration, wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com