Method for suspending motor rotor of micro motor mechanical pump

A technology of micro-machines and rotors, which is applied in the direction of controlling mechanical energy, electrical components, electromechanical devices, etc. It can solve the problems of poor positioning of the rotor center, low precision of rotor assembly, and complex systems, and achieves reduced vibration and noise, simple structure, and increased The effect of operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings.

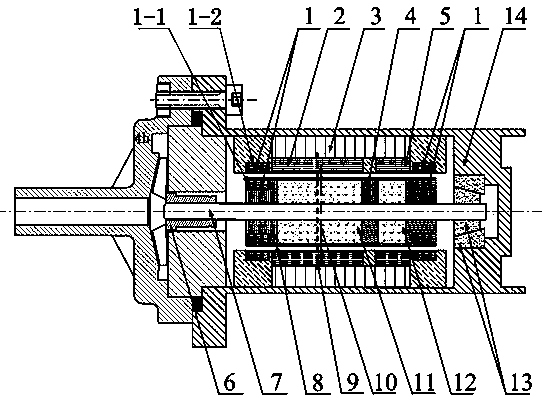

[0008] see figure 1 , the present invention includes a permanent magnetic bearing 1 , a stator assembly 3 , a rotor assembly 4 , and a tapered sliding bearing 13 . The permanent magnetic bearing 1 includes an inner magnetic steel ring 1-1 and an outer magnetic steel ring 1-2. The magnetic poles are in the same direction and exhibit repulsive force. The stator assembly 3 includes a secondary stator coil 2 and a primary stator coil 5. The rotor assembly 4 includes A secondary permanent magnet rotor 11, a primary permanent magnet rotor 12, a motor shaft 7, and a rotor protective sleeve 8. The secondary stator coil 2, the primary stator coil 5 and the outer magnetic steel ring 1-2 of the permanent magnetic bearing are potted and fixed on the motor casing 14 with epoxy resin, and the secondary permanent magnet rotor 11 and the primary permanent magnet rotor 12 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com