Machining machine tool of special pipe

A technology for processing machine tools and special-shaped pipes, which is applied in metal processing machinery parts, metal processing equipment, workpieces, etc., can solve the problems of inconvenient repeated positioning, complex structure of special-shaped pipes, and non-compliance with processing requirements of special-shaped pipes, and achieves good consistency. , The punching and cutting force is strong, the direction is stable and the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

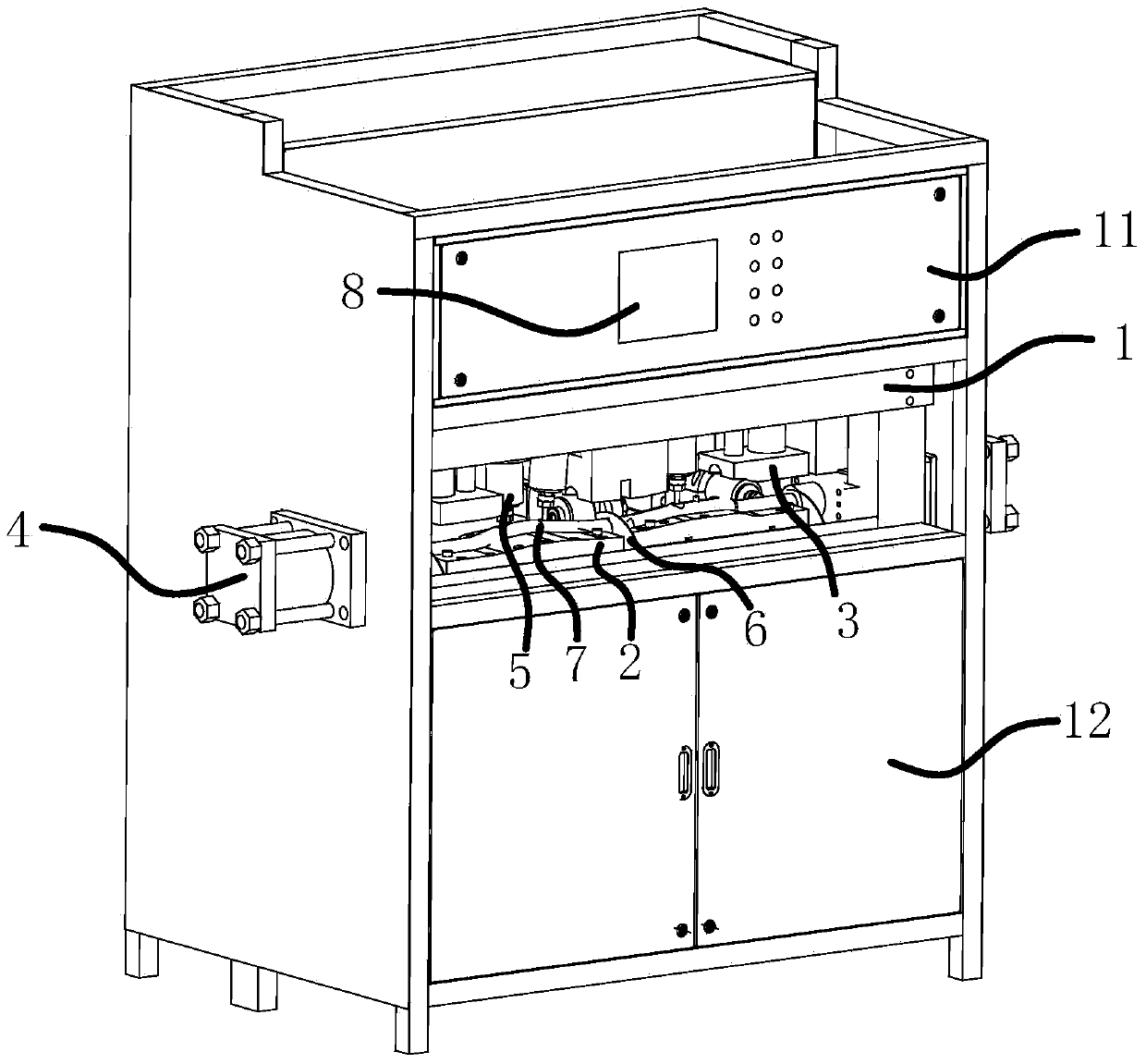

[0034] Examples, see figure 1 Shown: a machine tool for processing special-shaped pipes, including a frame 1, a positioning mechanism 2 installed on the frame 1, a clamping mechanism 3, a pipe end forming mechanism 4, a punching and cutting mechanism 5, a cutting mechanism 6 and a control system 8 , the frame 1 is in the shape of a cuboid, including an upper top surface 13, a lower bottom surface 14, a left side 15 and a right side 16, and an installation cabinet 12 is arranged below the frame 1, and an oil tank or an air pump is installed in the installation cabinet 12. An electrical cabinet 11 is installed above the frame 1, and the control system 8 is installed on the electrical cabinet 11.

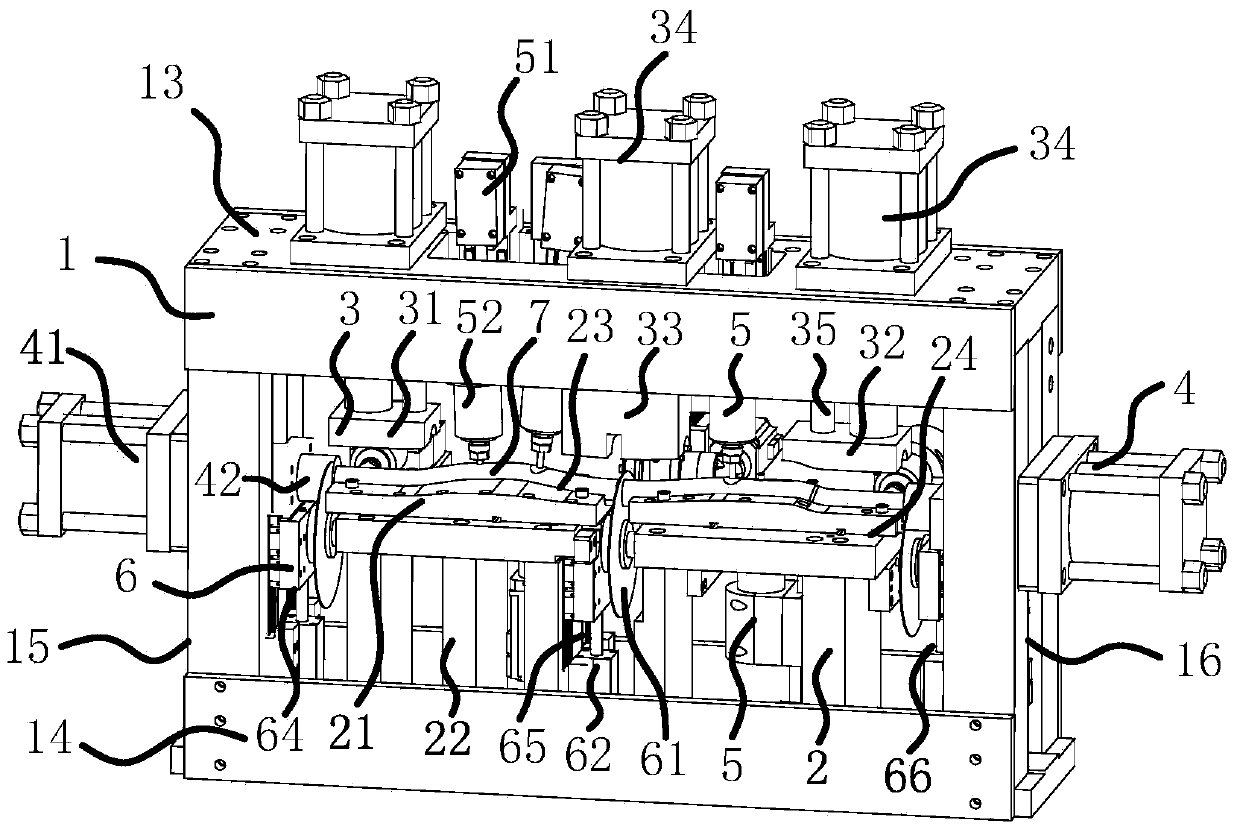

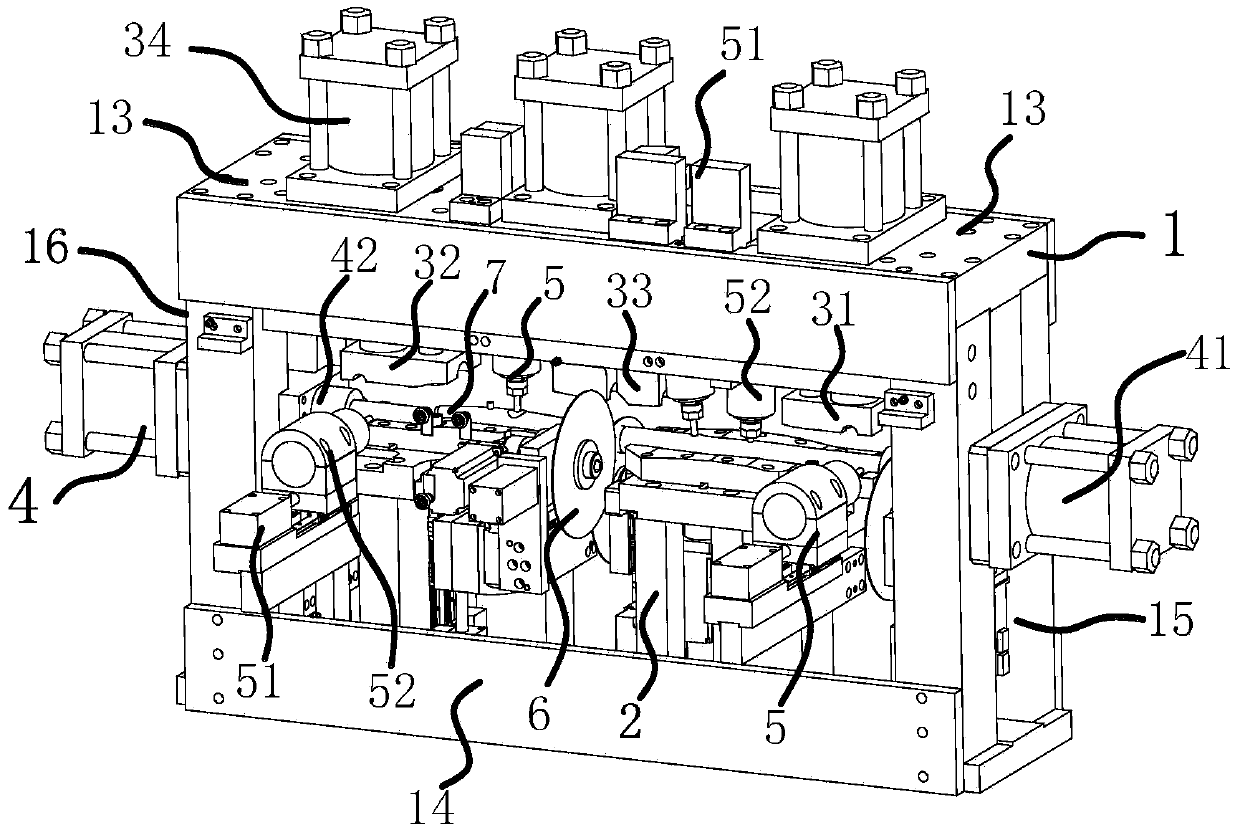

[0035] See Figure 2 to Figure 3 As shown: the positioning mechanism 2 is composed of several positioning modules 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com