Quick pneumatic cam clamping device

A clamper and fast technology, applied in the direction of clamping device, clamping, support, etc., can solve the problems of affecting the centering accuracy of the workpiece, affecting the production and processing efficiency, and reducing the processing accuracy of the workpiece, so as to improve production efficiency and shorten positioning Clamping time and the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

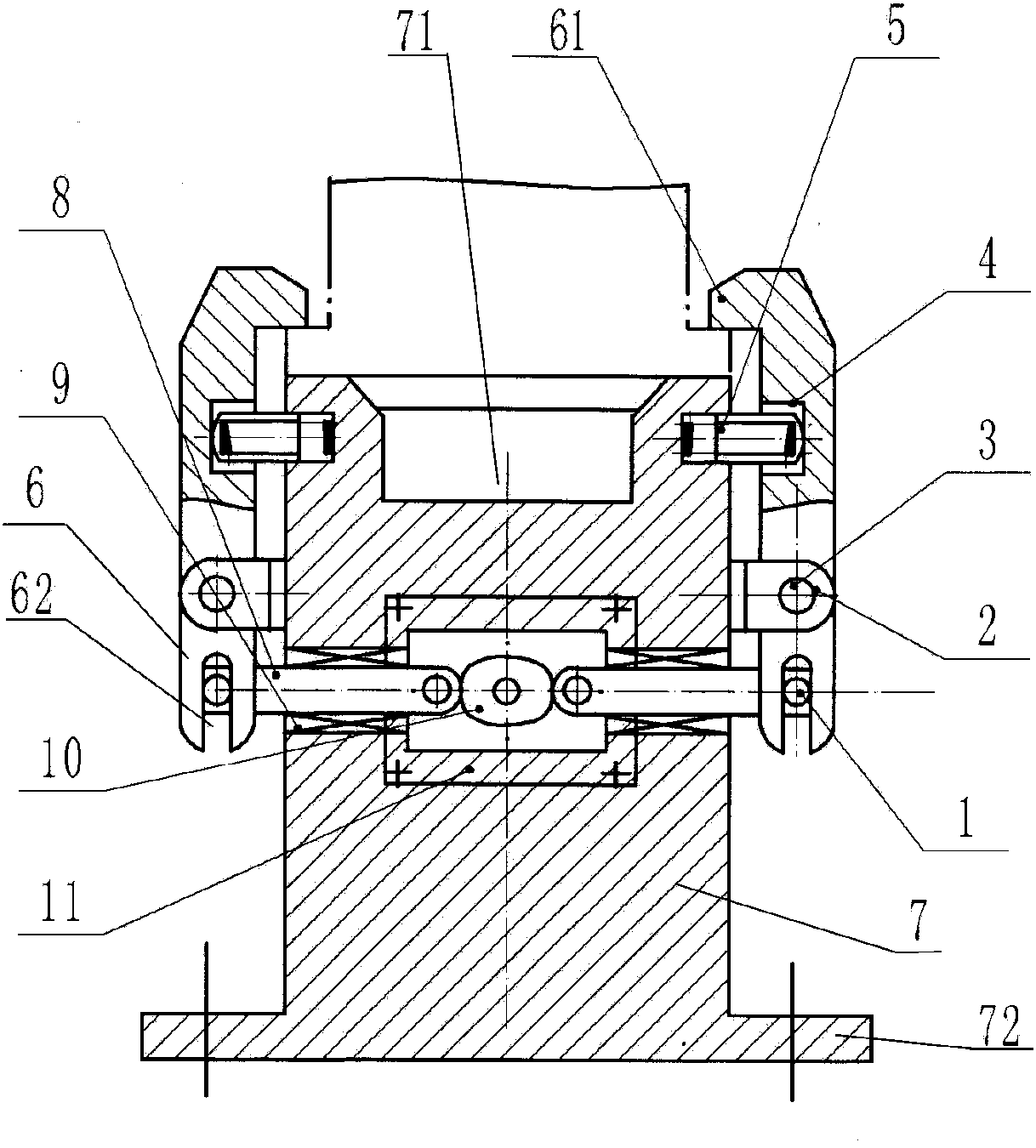

[0018] Such as figure 1 A pneumatic cam quick clamp shown includes bracket 2, pin I1, pin II3, return spring 5, pressure plate 6, base 7, push rod 8, linear bearing 9, double-sided cam 10 and rotary cylinder 11.

[0019] The rotary cylinder 11 is installed on the base 7, the double-sided cam 10 is installed on the rotary cylinder 11, and the base 7 on both sides of the double-sided cam 10 is respectively provided with a linear bearing 9, and the linear bearing 9 is provided with a push rod 8, and the push rod One end of 8 is in contact with double-sided cam 10, and the other end is provided with pin I1. Both sides of the base 7 are respectively provided with pressure plates 6, one end of the pressure plate 6 has a notch structure 62, and the other end is provided with a chuck 61, the chucks 61 of the two pressure plates 6 are arranged oppositely, and the pressure plate 6 is close to the groove structure. One side of 62 is provided with a pin II3, and the pin II3 movably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com