Anti-seize control system and method for ordinary drilling machine

A technology of control system and ordinary drilling machine, which is applied in the direction of manufacturing tools, metal processing machinery parts, metal processing, etc., can solve the problems of low processing accuracy, waste of resources, jamming, etc., to reduce the incidence of accidents, reduce maintenance costs, solve The effect of the stuck problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

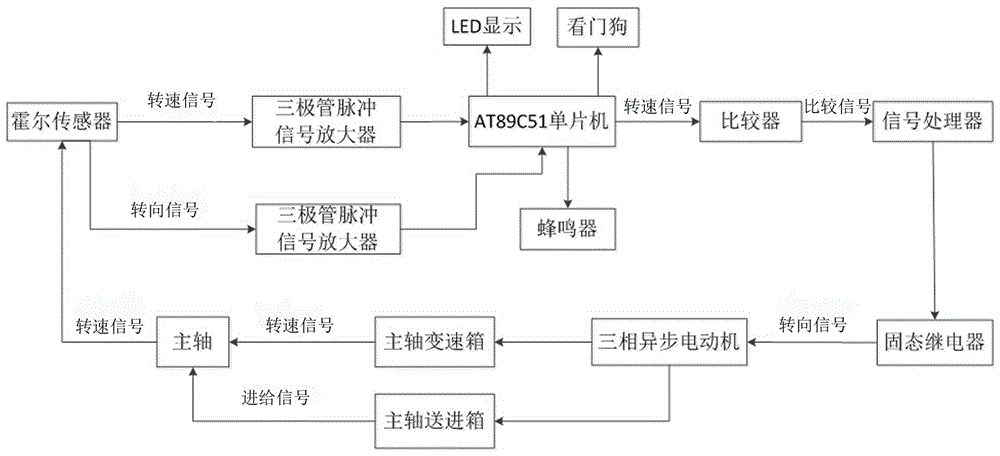

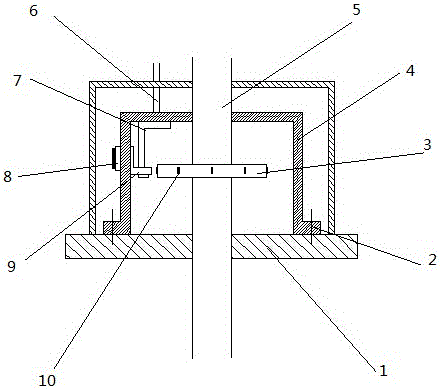

[0016] Such as figure 1 , 2 , an anti-jamming control system for ordinary drilling machines, including a spindle box base 1, an external fixed point 2, a speed plate 3, an internal support frame 4, a spindle 5, a signal output line 6, a triode pulse signal amplifier 7, and fixing screws 8. Hall sensor 9, magnetic sheet 10, AT89C51 microcontroller, comparator, signal processor, solid state relay, three-phase asynchronous motor, spindle gearbox, spindle feeding box, spindle, LED display, buzzer, watchdog The spindle gearbox and the spindle feeding box are fixedly installed in the spindle box, the Hall sensor is fixed on the spindle box, the input terminal of the triode pulse signal amplifier is connected to the Hall sensor, and the output terminal is connected to the input terminal of the AT89C51 single-chip microcomputer through the signal output line , the serial output port of the AT89C51 single-chip microcomputer is connected with the LED display and the comparator respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com