Preparation method for PEDOT (polymer ethylenedioxy thiophene)/nano titanium dioxide aqueous dispersion

A nano-titanium dioxide and dispersion technology, applied in the field of inorganic semiconductors and organic semiconductors, can solve problems such as the decrease of electrical conductivity, and achieve the effect of good electrical conductivity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

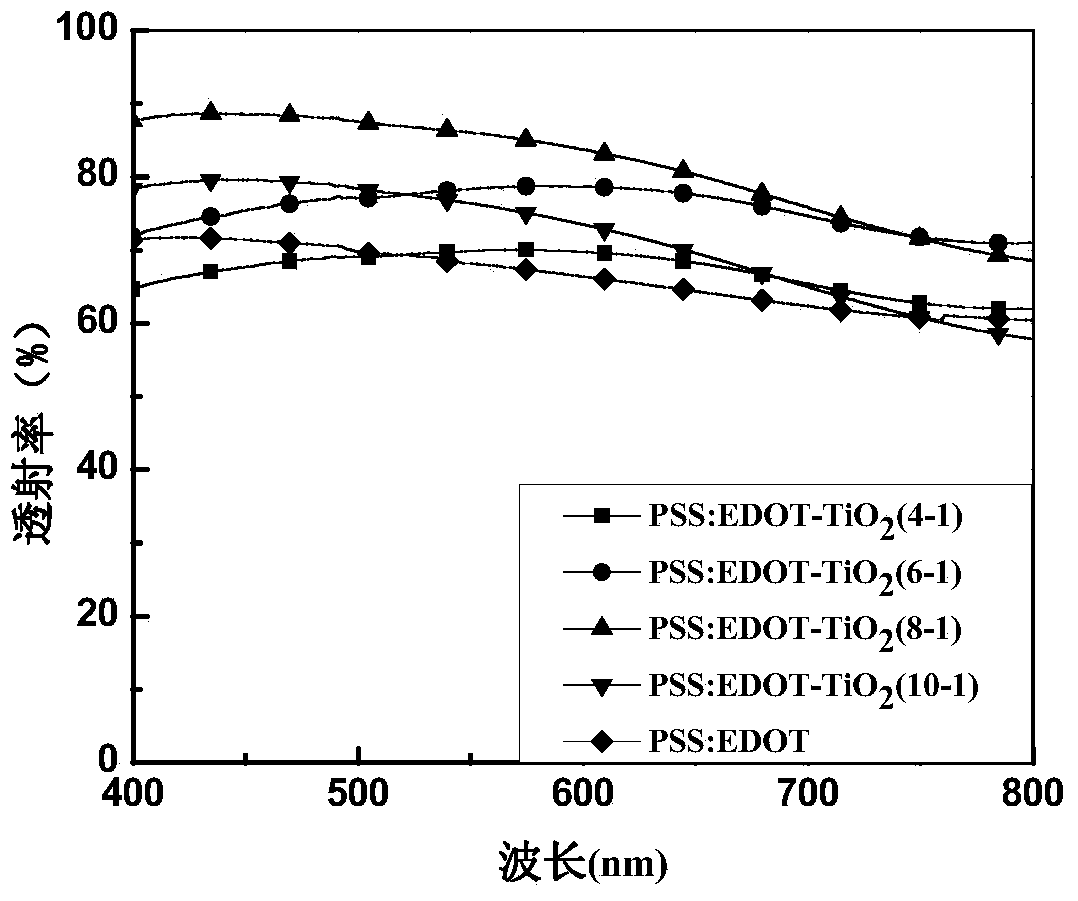

Image

Examples

Embodiment 1a

[0022] (1) At room temperature, add 1.6gPSS (Mn=40000), 0.64gEDOT, 0.8g nano-TiO to a 250ml reaction bottle 2 Dispersion (Nano TiO 2 The solid content of the dispersion is 20%), 80ml deionized water, dissolve and stir until clear, then add 3.08g (NH 4 ) 2 S 2 o 8 , 0.0036gFe 2 (SO 4 ) 3 , 40ml of deionized water, dissolved and stirred evenly, stirred and reacted at 35°C for 24 hours to obtain an aqueous dispersion;

[0023] (2) Centrifuge the aqueous dispersion prepared in step (1) to obtain solid-liquid stratification, remove the upper layer, take the lower layer of solid and dissolve it with distilled water to the quality of the initial aqueous dispersion, repeat the above operations three times (i.e. repeat 3 times After the operation of "centrifugation of the aqueous dispersion → removal of the upper layer → dissolving the solid in the lower layer with distilled water", the obtained aqueous dispersion was dispersed by ultrasonic (600W) for 1 hour to obtain the PEDOT...

Embodiment 1b

[0027] (1) At room temperature, add 0.64g EDOT and 0.8g nano-TiO to a 250ml reaction bottle 2 Dispersion (Nano TiO 2 The solid content of the dispersion is 20%), 80ml deionized water, dissolve and stir until clear, then add 3.08g (NH 4 ) 2 S 2 o 8 , 0.0036gFe 2 (SO 4 ) 3 , 40ml of deionized water, dissolved and stirred evenly, stirred and reacted at 35°C for 24 hours to obtain an aqueous dispersion;

[0028] (2) Centrifuge the aqueous dispersion prepared in step (1) to obtain solid-liquid stratification, remove the upper layer, take the lower layer of solid and dissolve it with distilled water to the quality of the initial aqueous dispersion, repeat the above operations three times (i.e. repeat 3 times After the operation of "centrifugation of the aqueous dispersion → removal of the upper layer → dissolving the solid in the lower layer with distilled water", the obtained aqueous dispersion was dispersed by ultrasonic (600W) for 1 hour to obtain the PEDOT / nano-titanium d...

Embodiment 2

[0032] (1) At room temperature, add 2.4gPSS (Mn=80000), 0.275gEDOT, 0.67g nano-TiO to a 250ml reaction bottle 2 Dispersion (Nano TiO 2 The solid content of the dispersion is 20%), 60ml deionized water, dissolve and stir until clear, then add 0.7672gK 2 S 2 o 8 , 0.0038gFe 2 (SO 4 ) 3 , 33ml of deionized water, dissolved and stirred evenly, stirred and reacted at 40°C for 18 hours to obtain an aqueous dispersion;

[0033] Step (2) is identical with embodiment 1. After the obtained PEDOT / nano-titanium dioxide dark blue aqueous dispersion was placed at 26° C. for 140 days, the dispersion liquid was observed and found to be transparent without delamination or precipitation.

[0034] The PEDOT / nano-titanium dioxide dark blue aqueous dispersion prepared in this example was coated on the PP film, dried at 80°C for 6 hours, and the resistance of the dried film was measured with four probes, and the surface sheet resistance was 247.1kΩ / □.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com