A new type of reinforced concrete drainage pipe and its manufacturing method

A technology for reinforced concrete and drainage pipes, applied in the direction of pipes/pipe joints/pipe fittings, coatings, sleeve/socket connections, etc. problems, to achieve the effect of strong integration, solving the problems of land subsidence and subsidence, and easy docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

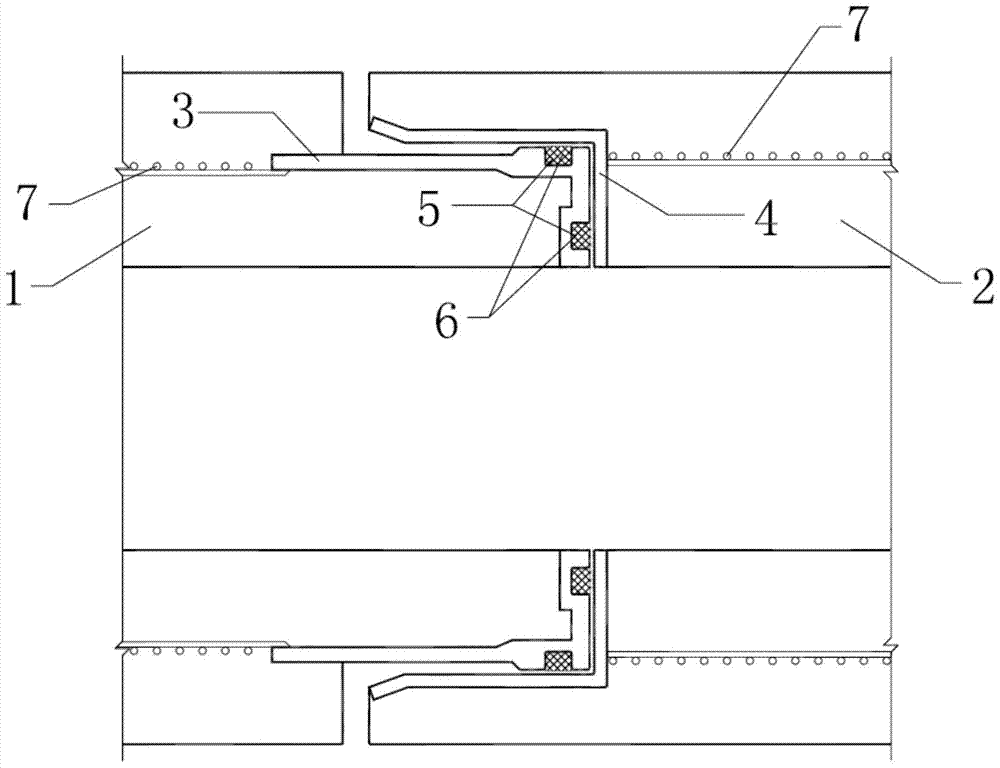

Image

Examples

Embodiment 1

[0028] The novel reinforced concrete drainage pipe material of the present embodiment is prepared by the following method, and the method comprises the following steps:

[0029] a. Production of reinforced concrete drainage pipes: Reactive Powder Concrete (RPC) is used as the raw material. The specific ingredients of the reactive powder concrete are cement: sand: quartz powder: silica fume according to the mass ratio of 2:0.5:0.32:0.15, The amount of water reducing agent is 2% of the total mass of cement, sand, quartz powder and silica fume, the length of steel fiber is 3-13mm, the diameter is 0.15-0.20mm, the volume content is 1%, and the water-binder ratio is 0.18. Use this raw material to make drainage pipes according to conventional methods. The compressive strength of RPC concrete with this optimal mass ratio can reach 150Mpa, while the thickness of the pipe wall can be reduced to about half of the conventional pipe, and the weight can be reduced to about 60% of the conven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com