3D-TSV (Through Silicon Via) in-situ tension test sample and preparation method thereof

A 3D-TSV, in-situ stretching technology, applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problem that the mechanical properties of the film cannot be completely replaced, the cylindrical material cannot be tested, and the size of the clamping part is too small and other problems to achieve the effect of optimizing multi-step molding design, improving preparation repeatability, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

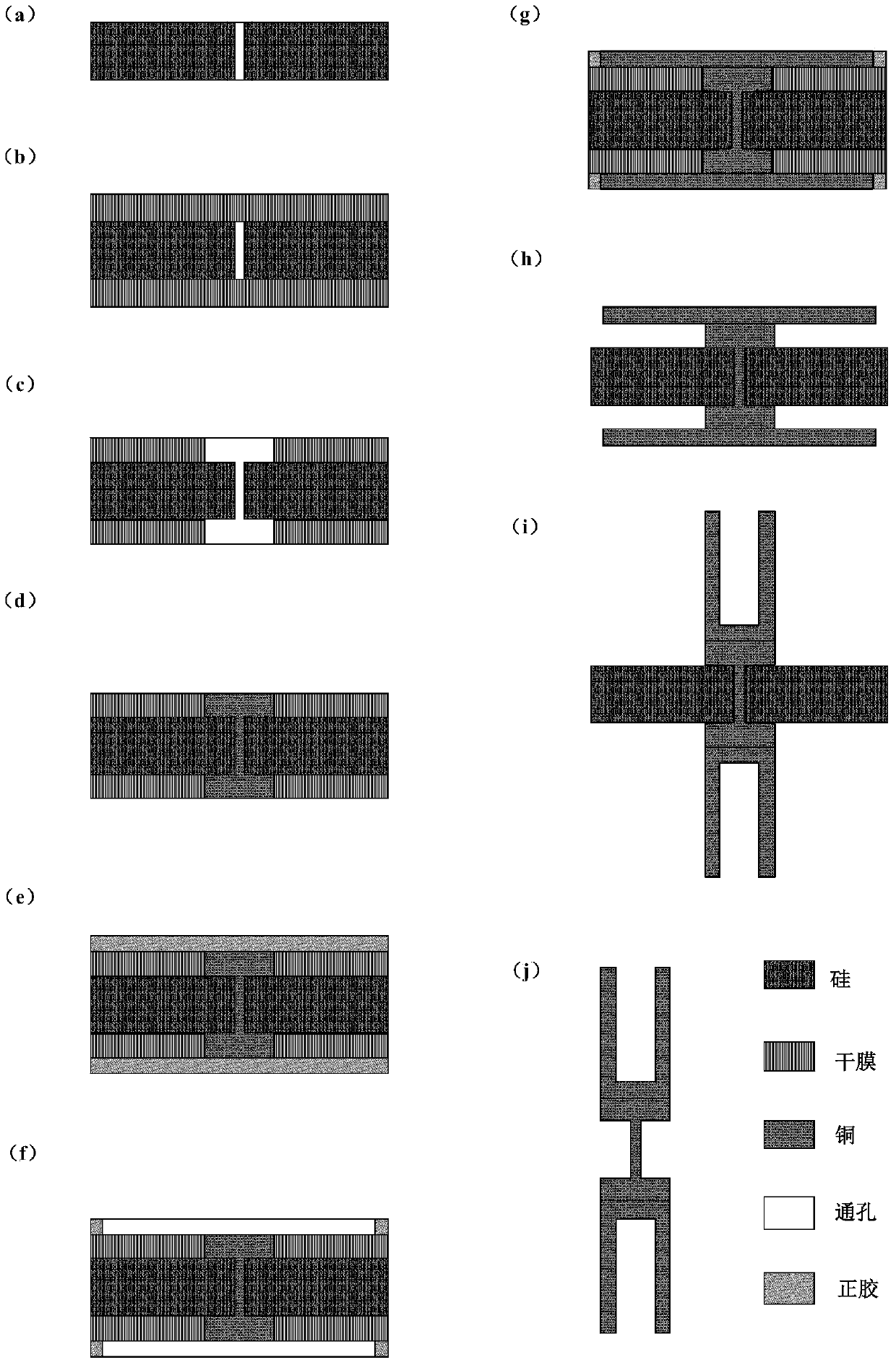

Method used

Image

Examples

Embodiment 1

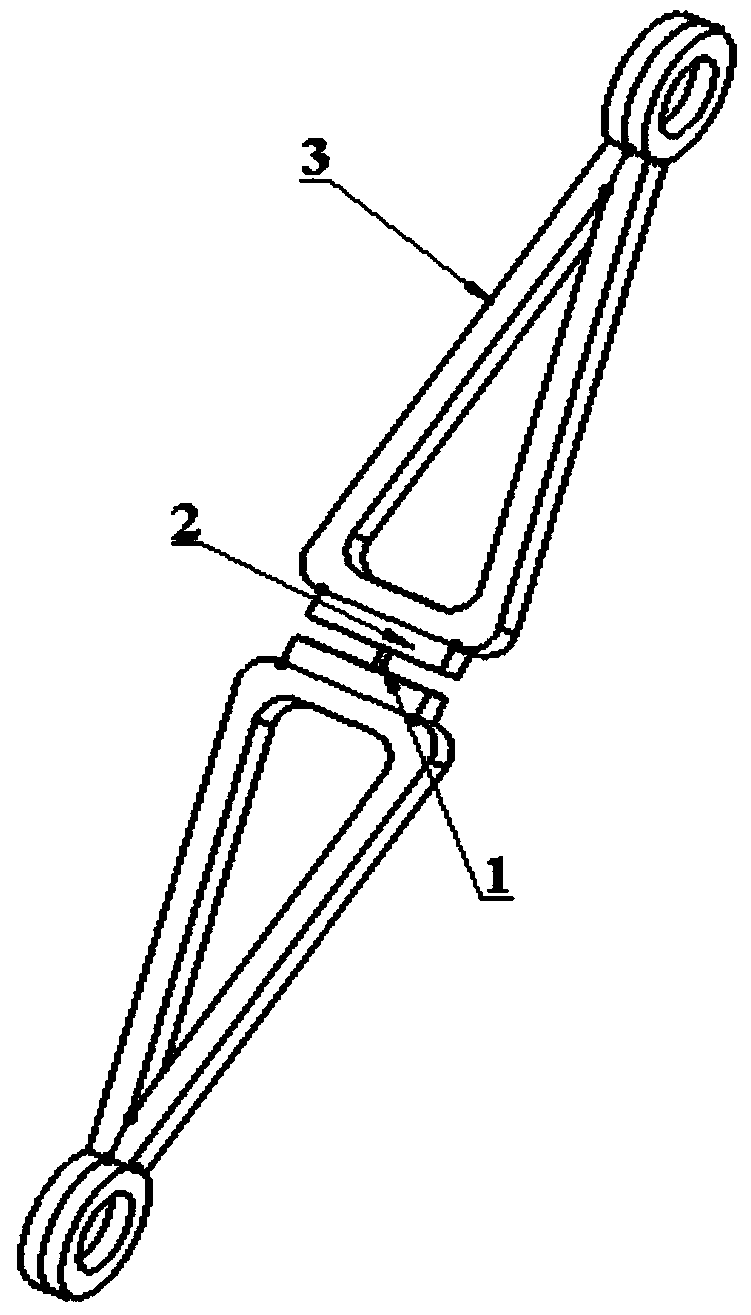

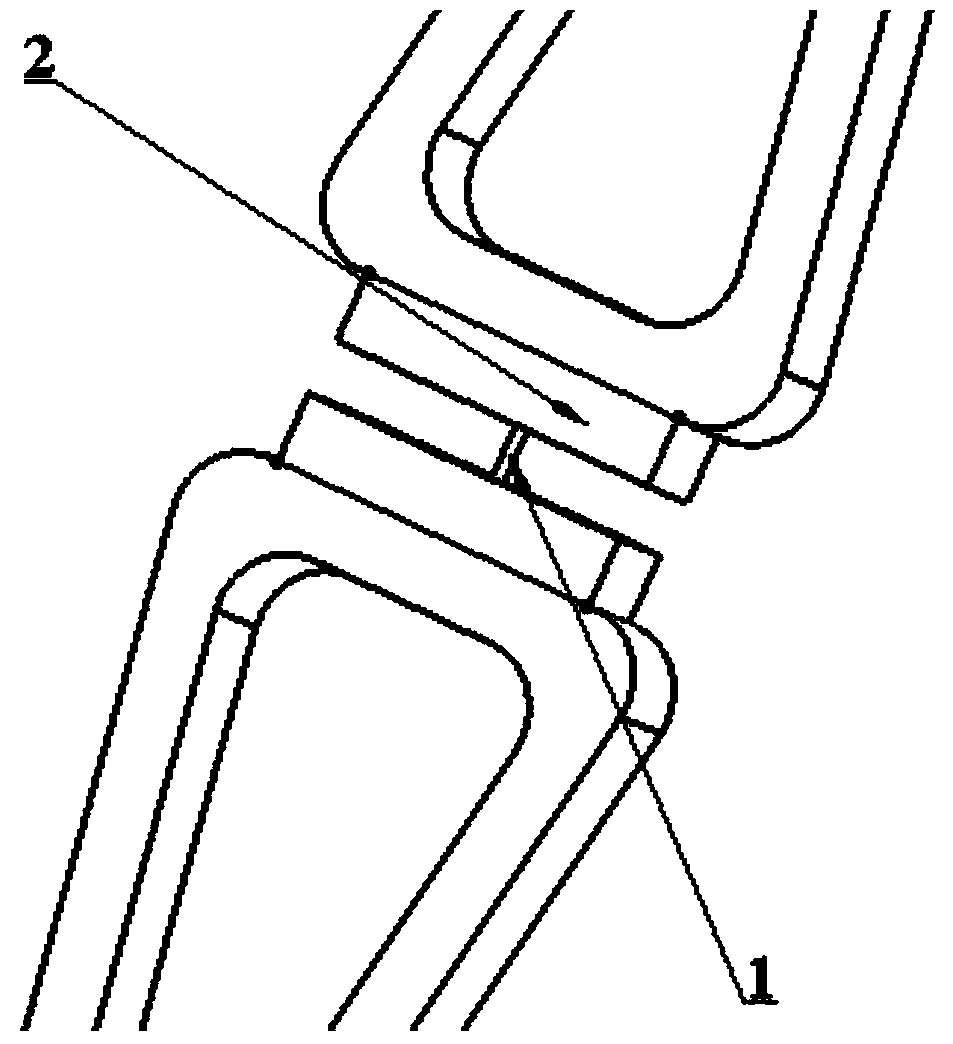

[0044] Such as figure 1 , 2 As shown, this embodiment provides an in-situ tensile sample for testing the mechanical properties of 3D-TSV copper interconnection materials. The in-situ tensile sample includes a sample column part 1, a fixed part 2 and a clip The holding parts 3 are prepared and interconnected by electroplating, wherein:

[0045] The sample column part 1 is a metal column formed in a through-silicon via, and the material of the metal column is copper;

[0046] The fixed part 2 is a metal block that completes the growth together with the sample column part, and replaces the sample column part 1 in the sample column part 1 prepared by electroplating when the clamping part 3 is bent to prevent the test Part 1 of the sample column is deformed; the material of the metal block is copper;

[0047] The clamping part 3 is an electroplated metal with a ring connected to the fixed part 2, and the material is copper or nickel.

[0048] In this embodiment, the shape of the ...

Embodiment 2

[0064] Such as Figure 4 , 5 As shown, this embodiment provides an in-situ tensile sample for testing the mechanical properties of 3D-TSV copper interconnection materials. The in-situ tensile sample includes a sample column part 1, a fixed part 2 and a clip The holding part 3, the sample column part 1, the fixing part 2 and the clamping part 3 are connected to each other by adhesive or welding, wherein:

[0065] The sample column part 1 is a metal column formed in a through-silicon via, and the material is copper;

[0066] The fixed part 2 is a metal block that completes the growth together with the sample column part 1, and is used to provide the clamping part 3 with a sufficient contact area to ensure that the force acts directly on the sample column part 1 during the stretching process. for copper;

[0067] The clamping part 3 is a metal structure connected with the fixed part 2 and has a ring, which is prepared separately and plays a clamping role in actual operation, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com