Process for manufacturing electroless copper electroplating via hole type double-sided circuit board through UV printing method

A technology of via holes and circuit boards, which is applied in the directions of printed circuits, printed circuit manufacturing, and electrical connection formation of printed components, etc. It can solve the problems of high processing costs, many processing hours, and high material costs, and achieve high processing efficiency and low processing hours. The effect of less and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

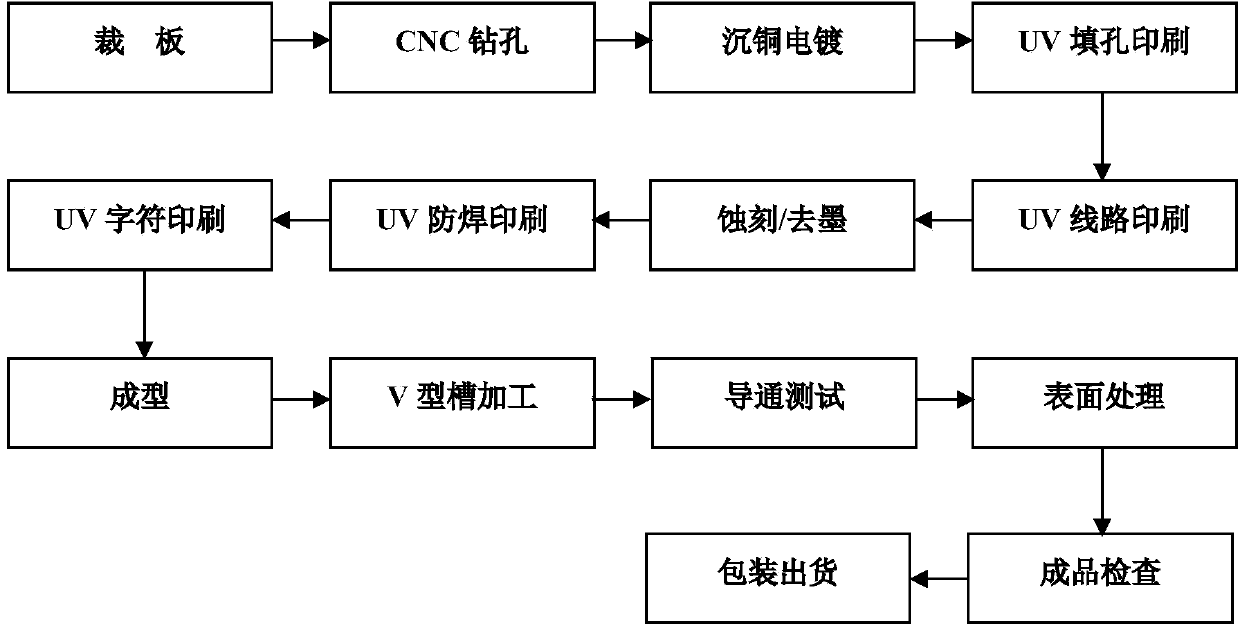

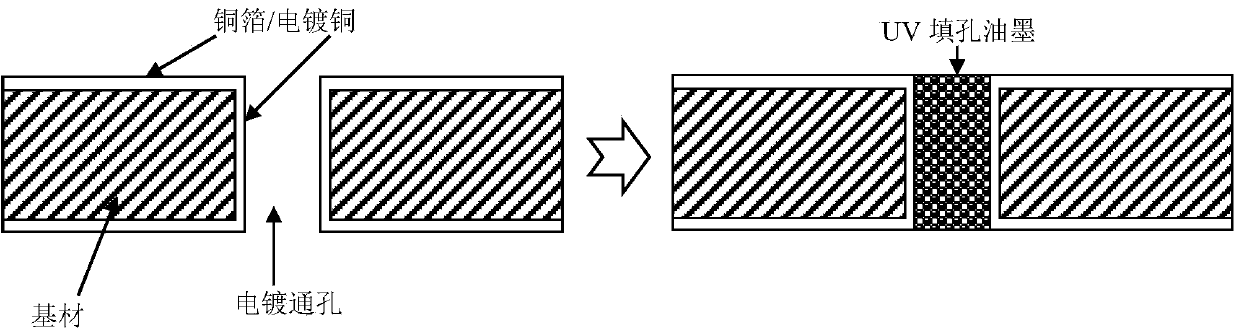

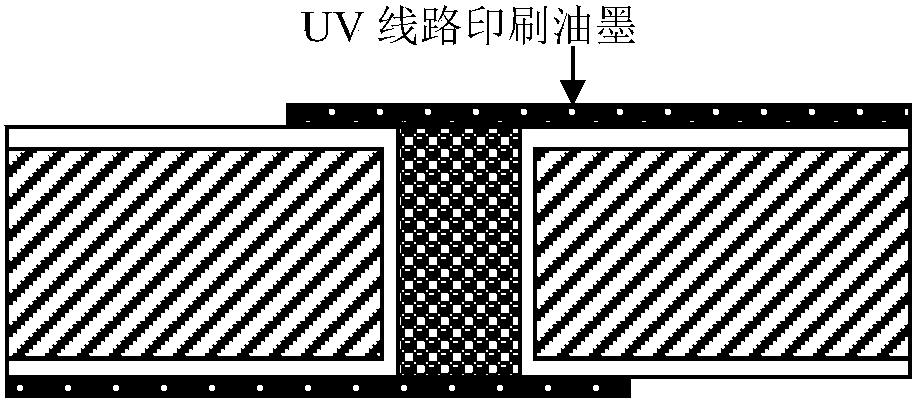

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a UV printing process for manufacturing double-sided circuit boards with copper plated via holes includes cutting board—CNC drilling—copper plating—UV hole filling printing—UV circuit printing—etching / ink removal—UV Solder mask printing—UV character printing—forming—V-groove processing—conduction test—surface treatment—finished product inspection—packaging and shipping, the specific process is as follows:

[0039] (1) Cutting board: Cut the large-area copper-clad laminate provided by the manufacturer into the working size required for production;

[0040] (2) CNC drilling: Drill through holes on the cut copper-clad laminates, which are used to connect the plug-in holes of copper plating and welding parts on both sides of the circuit;

[0041] (3) Copper sinking electroplating: copper sinking electroplating treatment for via holes used for line connection;

[0042] (4) UV hole-fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com