Catalyst packing device of bubble tower-type slurry bed reactor and catalyst packing method of bubble tower-type slurry bed reactor

A filling device and filling method technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve problems such as clogging of pipes or valves, and achieve the effect of avoiding mechanical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

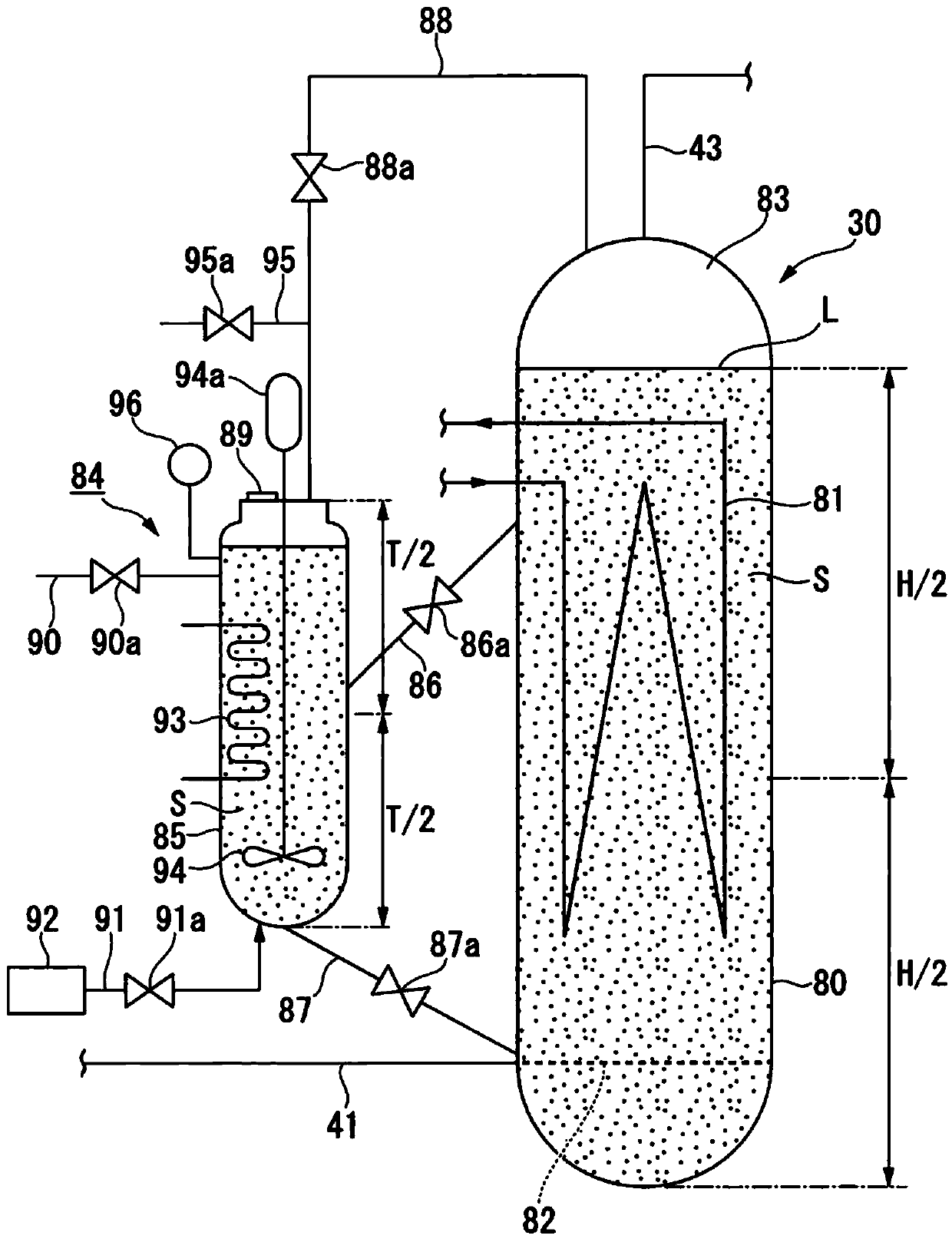

[0043] Next, the catalyst filling device for the bubble column slurry bed reactor and the catalyst filling method for the bubble column slurry bed reactor of the present invention will be described in detail.

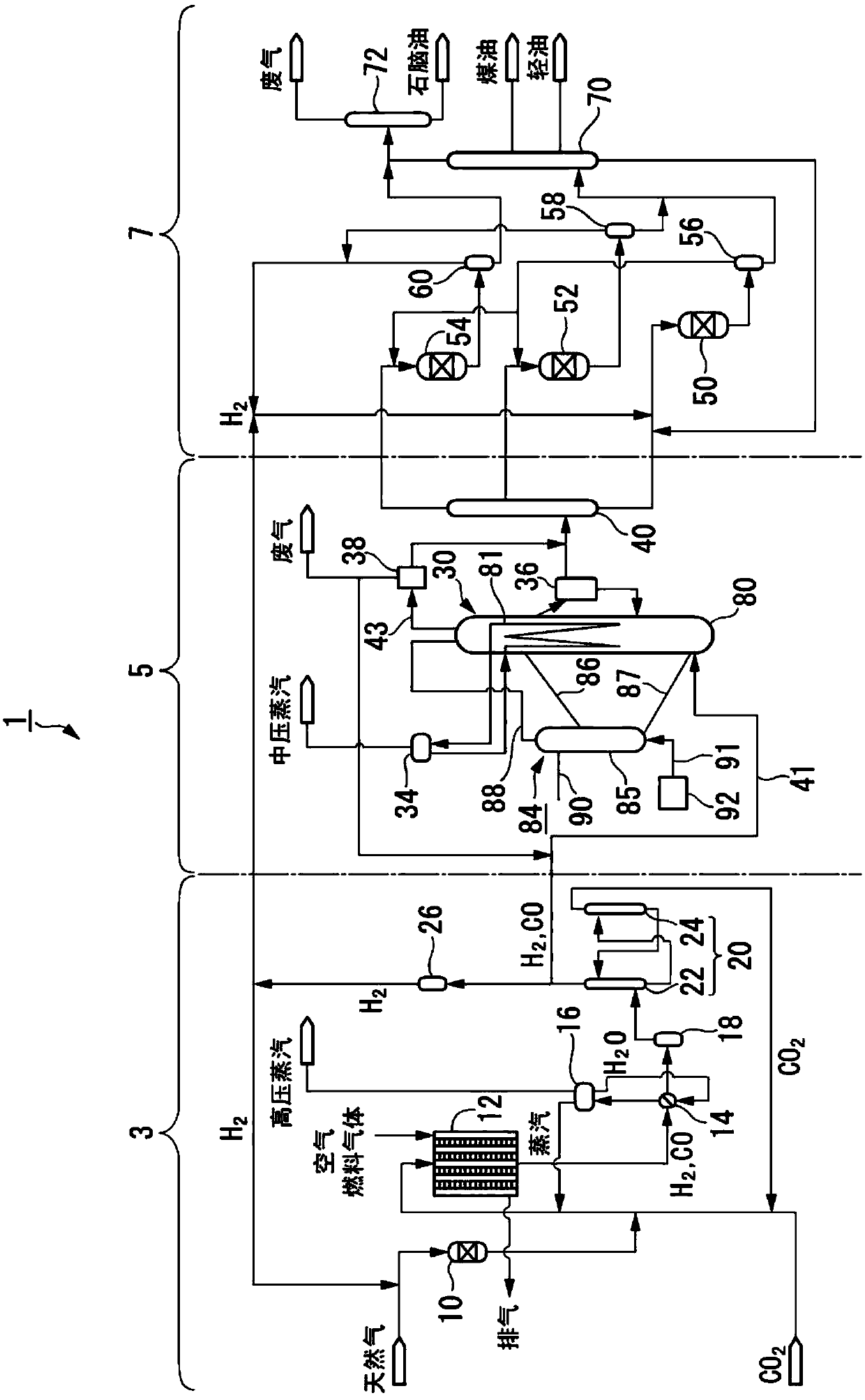

[0044] First, refer to figure 1 A liquid fuel synthesis system including a bubble column type slurry bed reactor according to the present invention will be described.

[0045] figure 1 The liquid fuel synthesis system 1 shown is a factory equipment for implementing the GTL process of converting hydrocarbon raw materials such as natural gas into liquid fuels.

[0046] The liquid fuel synthesis system 1 is composed of a synthesis gas production unit 3 , an FT synthesis unit 5 , and a product refining unit 7 . The synthesis gas production unit 3 reforms natural gas which is a hydrocarbon raw material to produce synthesis gas containing carbon monoxide gas and hydrogen gas. The FT synthesis unit 5 synthesizes liquid hydrocarbons from the synthesis gas produced in the syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com