Method for making color-changing simulated plants

A technology for simulating plants and a production method, applied in the field of simulating plants, can solve problems such as small living space, and achieve the effects of convenient life, reduced space occupied, and reduced waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method for making the color-changing simulated plant of the present invention is realized through the following preparation process: comprising the following steps:

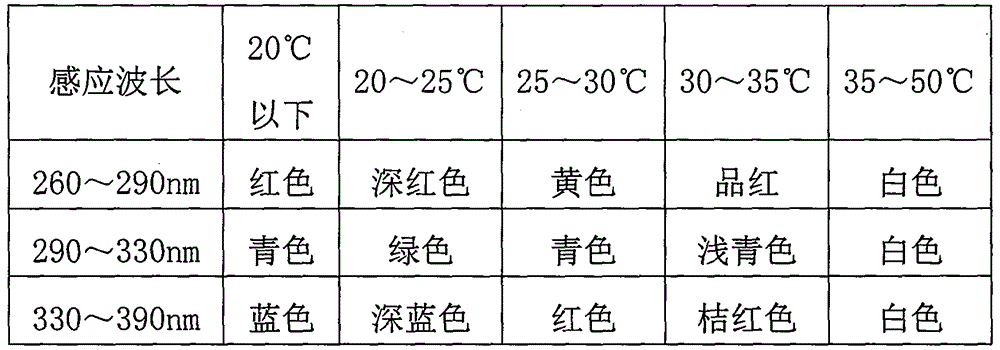

[0027] a, prepare 100kg of color-changing paint, which is formulated by the following components: water is 40kg; 3,3-bis(4-dimethylaminophenyl)-6-dimethylaminophenyl peptide is 3kg, diphenol base Propane is 9kg, photochromic additive is 3kg; hydroxypropyl methylcellulose is 13kg, 3-diethylamino-7,8-benzofuran is 5kg, ethylene-vinyl acetate copolymer is 4kg, phenylethyl alcohol oleate 6kg for sodium lactate, 12kg for acrylic resin, and 5kg for acrylic resin.

[0028] The preparation technology of described discoloration paint comprises the steps:

[0029] a1, water with a predetermined weight of 40kg, 3kg of 3,3-bis(4-dimethylaminophenyl)-6-dimethylaminophenylpeptide and 9kg of diphenolic propane are dropped into the water successively to make 3,3- Bis(4-dimethylaminophenyl)-6-dimethylaminophenyl pept...

Embodiment 2

[0043] The method for making the color-changing simulated plant of the present invention is realized through the following preparation process: comprising the following steps:

[0044] a, prepare 100kg of color-changing paint, which is formulated by the following components: water is 30kg; 3,3-bis(4-dimethylaminophenyl)-6-dimethylaminophenyl peptide is 6kg, diphenol base Propane is 10kg, photochromic additive is 1kg; hydroxypropyl methylcellulose is 15kg, 3-diethylamino-7,8-benzofuran is 6kg, ethylene-vinyl acetate copolymer is 5kg, phenylethyl alcohol oleate is 3kg, sodium lactate is 18kg, and acrylic resin is 6kg.

[0045] The preparation technology of described discoloration paint comprises the steps:

[0046] a1, 30kg of water is scheduled, and 6kg of 3,3-bis(4-dimethylaminophenyl)-6-dimethylaminophenylpeptide and 10kg of diphenolic propane are successively dropped into the water to make 3,3-bis (4-dimethylaminophenyl)-6-dimethylaminophenyl peptide and diphenolic propane...

Embodiment 3

[0059] The method for making the color-changing simulated plant of the present invention is realized through the following preparation process: comprising the following steps:

[0060] a, prepare 100kg of color-changing paint, which is formulated by the following components by weight: water is 45kg; 3,3-bis(4-dimethylaminophenyl)-6-dimethylaminophenyl peptide is 5kg, diphenol base Propane is 12kg, photochromic additive is 1kg; hydroxypropyl methylcellulose is 10kg, 3-diethylamino-7,8-benzofuran is 8kg, ethylene-vinyl acetate copolymer is 3kg, phenylethyl alcohol oleate is 3.5kg, sodium lactate is 10kg, and acrylic resin is 2.5kg.

[0061] The preparation technology of described discoloration paint comprises the steps:

[0062] a1, 45kg of water is scheduled, and 5kg of 3,3-bis(4-dimethylaminophenyl)-6-dimethylaminophenylpeptide and 12kg of diphenolic propane are successively dropped into the water to make 3,3-bis (4-dimethylaminophenyl)-6-dimethylaminophenyl peptide and diph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com