Method for preparing bismuth hydroxide/bismuth tungstate compound photo-catalyst by heating one-pot solvent

A solvothermal method and composite light technology, which are applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effect of simple and economical preparation process and easy to scale up production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

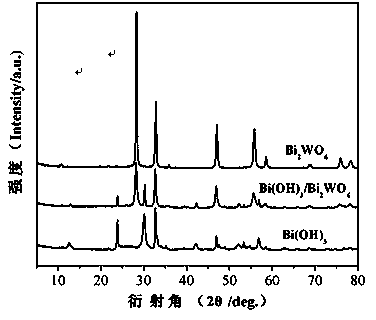

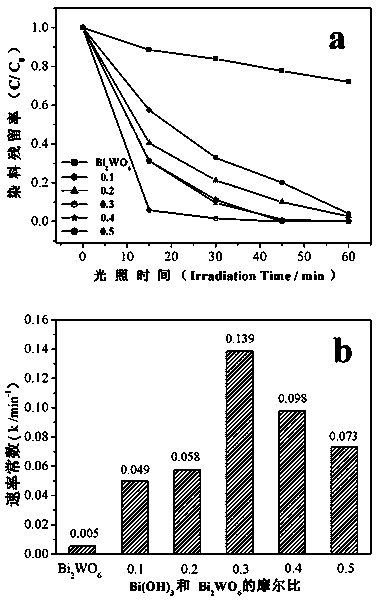

Embodiment 1

[0040] Weigh 0.40mmol Na 2 WO 4 2H 2 O, add 3.0ml distilled water and stir until fully dissolved; weigh 0.84mmol Bi(NO 3 ) 3 ·5H 2 O in a 25ml polytetrafluoroethylene reactor lining, add 5ml distilled water and magnetically stir for 15min, Na 2 WO 4 2H 2 The O solution was added dropwise into the reaction kettle, and magnetic stirring was continued for 30 min, then 9.0 ml of absolute ethanol was added dropwise, and after stirring for 10 min, the suspension was solvothermally reacted at 200° C. for 6 h. After cooling to room temperature, the product was centrifuged, washed and dried to obtain Bi(OH) 3 / Bi 2 WO 6 -0.1 photocatalyst sample. By adjusting Bi(NO 3 ) 3 ·5H 2 The amount of O, repeat the above operation, can get different compound ratio of Bi(OH) 3 / Bi 2 WO 6 Composite photocatalyst, performance as attached image 3 Described. As explained above, Bi(OH) 3 It is a product, not a reactant, but an excess of Bi(NO 3 ) 3 ·5H 2 O, and Bi(OH) was obtaine...

Embodiment 2

[0042] Weigh 0.40mmol Na 2 WO 4 2H 2 O, add 3ml of distilled water and stir until fully dissolved; weigh 0.92mmol Bi(NO 3 ) 3 ·5H 2 O in the polytetrafluoroethylene reactor liner of 25ml, add 11ml distilled water and magnetically stir for 15min, Na 2 WO 4 2H 2The O solution was added dropwise into the reaction kettle, continued magnetic stirring for 30 min, added dropwise 3.0 ml of absolute ethanol, stirred for 10 min, and reacted the white suspension at 180° C. for 6 h by solvothermal reaction. After being cooled to room temperature, the product was centrifuged, washed and dried to obtain an alcohol-water volume ratio of 3:14, Bi(OH) 3 / Bi 2 WO 6 -0.3 Pale yellow photocatalyst powder. By adjusting the ethanol content and repeating the above operation, a series of Bi(OH) with different ethanol content can be obtained. 3 Bi(OH) with a molar ratio of 0.3 3 / Bi 2 WO 6 composite photocatalyst.

[0043] Table 1 Bi(OH) 3 / Bi 2 WO 6 -0.3, the photocatalytic perform...

Embodiment 3

[0047] Weigh 0.40mmol Na 2 WO 4 2H 2 O, add 3ml of distilled water and stir until fully dissolved; weigh 0.88mmol Bi(NO 3 ) 3 ·5H 2 O in the polytetrafluoroethylene reactor liner of 25ml, add 5ml distilled water and magnetically stir for 15min, Na 2 WO 4 2H 2 The O solution was added dropwise into the reaction kettle, and magnetic stirring was continued for 30 minutes, then 9ml of absolute ethanol was added dropwise, and after stirring for 10 minutes, the white suspension was solvothermally reacted at 160°C for 12 hours. After cooling to room temperature, the product was centrifuged, washed and dried, and Bi(OH) with a molar ratio of 0.2 3 / Bi 2 WO 6 Photocatalyst samples. By setting the temperature at 160°C, 180°C, 200°C, and adjusting the Bi(NO 3 ) 3 ·5H 2 The amount of O, repeat the above operation, you can get a series of Bi(OH) with different molar ratios under different reaction temperature conditions 3 / Bi 2 WO 6 composite photocatalyst.

[0048] Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com